Fermentation freezing solid dairy product and preparation method thereof

A dairy product and fermented milk technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as inapplicability, achieve high viable bacteria count, good flavor and taste, and optimize the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

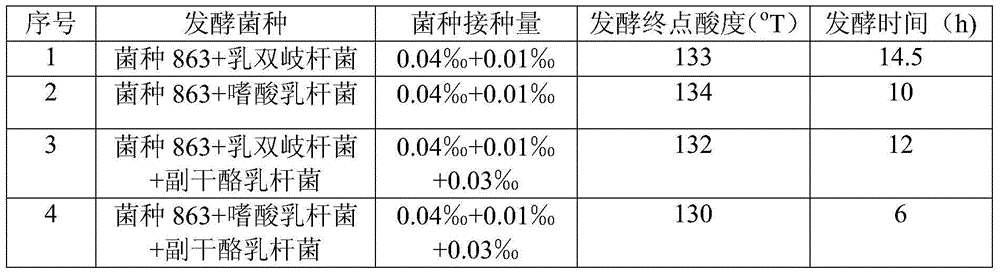

Method used

Image

Examples

Embodiment 1

[0063] Preparation of fermentation bottom material liquid: fully mix 8% white sugar, 25% cream, 10% skim milk powder, locust bean gum and monoglyceride fatty acid ester (3:5 by weight) 4‰ and the rest of water, The total solids content of the fermentation bottom material liquid is 43%. The fermentation bottom material liquid is homogenized (primary pressure 50MPa, secondary pressure 180MPa), sterilized at 90°C for 300s and then cooled to 43°C, inoculated with strains 863, Lactobacillus acidophilus and Lactobacillus paracasei, the total inoculum amount is 0.04‰, the weight ratio of strain 863, Lactobacillus acidophilus and Lactobacillus paracasei is 4:1:3, and the temperature is stirred at 50 rpm Ferment at 43°C until the titrated acidity reaches 130°T to obtain fermented milk;

[0064] Mix the fermented milk and the post-mixture at a weight ratio of 4:1 to obtain a frozen yogurt mixture; the post-mixture consists of 40% white sugar, 5% anhydrous butter, 15% fructose syrup, loc...

Embodiment 2

[0067] Preparation of fermentation bottom material liquid: fully mix white granulated sugar 4%, anhydrous butter 20%, whole milk powder 15%, locust bean gum 3.5‰ and the rest of water, the total solid content of the fermentation bottom material liquid is 42 %, the fermentation bottom material liquid is cooled to 43°C after being homogenized and sterilized, inoculated with fermentation strains, fermented under stirring at 40 rpm, and fermented to a titrated acidity of 135°T to obtain fermented milk; The fermentation strains are strain 863, Lactobacillus acidophilus and Lactobacillus paracasei, and the dosages thereof are 0.03‰, 0.01‰ and 0.025‰ respectively.

[0068] Mix the fermented milk and the post-mixture at a weight ratio of 8:1 to obtain a frozen yogurt mixture; the post-mixture consists of 35% white sugar, 6% 82 cream, 20% glucose syrup, and 4‰ of locust bean gum and the remaining amount of water are mixed, homogenized, sterilized and cooled;

[0069] The resulting fro...

Embodiment 3

[0071]Preparation of fermentation bottom material liquid: fully mix white granulated sugar 12%, cream 30%, skim milk powder 25%, locust bean gum 5‰ and the rest of the water, the total solid content of the fermentation bottom material liquid is 46%, The fermentation bottom material liquid is cooled to 43°C after being homogenized and sterilized, inoculated with fermentation strains, fermented under stirring at 60 rpm, and fermented to a titrated acidity of 145°T to obtain fermented milk; the fermented strain The species are strain 863, Lactobacillus acidophilus, Lactobacillus paracasei, the dosages are 0.04‰, 0.01‰ and 0.03‰ respectively;

[0072] Mix the fermented milk and the post-mixture at a weight ratio of 18:1 to obtain a frozen yogurt mixture; the post-mixture consists of 50% white sugar, 10% anhydrous butter, 10% maltose, and locust bean gum 4‰ and the remaining amount of water are mixed, homogenized, sterilized and cooled;

[0073] The resulting frozen yoghurt mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com