Saussurea involucrate culture composition and glossy ganoderma tea and preparation method thereof

A technology of snow lotus culture and composition, which is applied in the field of snow lotus composition Ganoderma lucidum tea and its preparation, which can solve the problems of poor taste and difficult to solve the bitter taste, improve the taste and fragrance, solve the difficulty of artificial planting, and make up for the gaps in utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

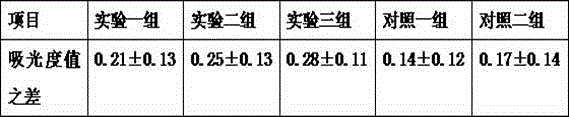

Embodiment 1

[0029] Take 4kg fresh fruit of snow lotus culture for ultrasonic cleaning, let it cool for 12 hours, set the temperature of the hot air blower at 80°C, preheat the fresh fruit of snow lotus culture for 30 minutes, then enter the microwave killing machine, evacuate until the vacuum degree is less than 20Pa, and then put it in the microwave The chamber of the degreening machine is filled with argon gas, under the microwave power of 2000W, intermittent microwave irradiation, irradiating for 1min, intermittently for 1min, irradiating 10 times in this way, after the completion, leave the chamber for vacuum drying, and crush the dried snow lotus culture fresh fruit ; Take 1 kg of snow lotus culture and carry out ultrasonic cleaning, then carry out vacuum drying at 55 ° C, and then pulverize by a pulverizer to obtain snow lotus culture powder; then mix the crushed snow lotus culture fresh fruit, 1 kg of water and 0.4 kg of protease , and stirred at room temperature for 1 hour; followe...

Embodiment 2

[0032] Take 2kg fresh fruit of snow lotus culture for ultrasonic cleaning, let it cool for 12 hours, set the temperature of the hot air blower at 90°C, preheat the fresh fruit of snow lotus culture for 30 minutes, then enter the microwave killing machine, vacuumize until the vacuum degree is less than 20Pa, and then put it in the microwave The chamber of the degreening machine is filled with argon gas, under the microwave power of 2000W, intermittent microwave irradiation, irradiating for 1min, intermittently for 1min, irradiating 10 times in this way, after the completion, leave the chamber for vacuum drying, and crush the dried snow lotus culture fresh fruit Get 1kg snow lotus culture after ultrasonic cleaning, carry out vacuum drying at 55 ℃, then pulverize by pulverizer, obtain snow lotus culture powder; Then the fresh fruit of snow lotus culture after pulverization, 0.4kg water and 0.1kg protease are processed Mix and stir at room temperature for 1 hour; then carry out ult...

Embodiment 3

[0035] Take 3kg fresh fruit of snow lotus culture for ultrasonic cleaning, let it cool for 12 hours, set the temperature of the hot air blower at 100°C, preheat the fresh fruit of snow lotus culture for 30 minutes, and then enter the microwave killing machine, vacuumize until the vacuum degree is less than 20Pa, and then put it in the microwave The chamber of the degreening machine is filled with argon gas, under the microwave power of 2000W, intermittent microwave irradiation, irradiating for 1min, intermittently for 1min, irradiating 10 times in this way, after the completion, leave the chamber for vacuum drying, and crush the dried snow lotus culture fresh fruit Get 1kg snow lotus culture after ultrasonic cleaning, carry out vacuum drying at 55 ℃, then pulverize by pulverizer, obtain snow lotus culture powder; Then the fresh fruit of snow lotus culture after pulverization, 0.65kg water and 0.24kg protease are processed Mix and stir at room temperature for 1 hour; then carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com