Gold/quaternary carbon dot core-shell nanocomposite and preparation method thereof

A nano-composite material and composite material technology, which are applied in the field of gold/quaternary carbon point core-shell nano-composite materials and preparation, can solve the problems of implanted heat source, low heating efficiency, uneven thermal field distribution, etc. Good, low toxicity, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

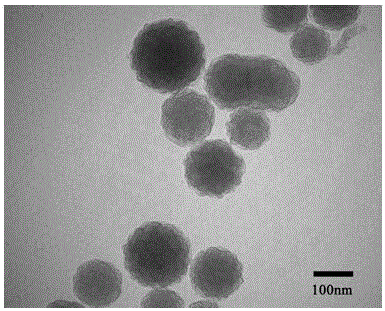

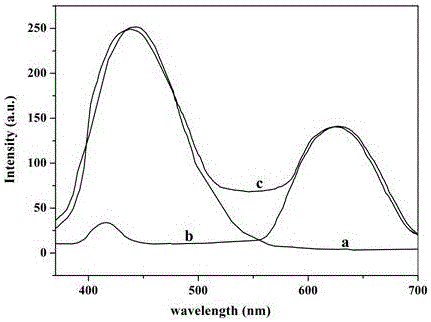

Image

Examples

Embodiment 1

[0021] (1) Preparation of quaternary carbon dots:

[0022] Weigh 1 g of betaine hydrochloride and dissolve it in 20 mL of deionized water, then add tris in a molar ratio of 1:1, and after it is completely dissolved, add excess isopropanol, and the obtained slurry is at 70 o Dry under vacuum at C for 36h. Muffle furnace 250 for dried sticky white matter o After heating at C for 2 hours, 0.8 g of brown solid was obtained, which was added to 50 mL of deionized water. The amount of deionized water used here was 50-100 times the weight of the brown solid, and the formed brown dispersion was precipitated with 65 mL of acetone. , the dosage ratio of acetone and deionized water in the brown dispersion liquid is 1:1-2:1, and the dark brown powder can be obtained by drying at room temperature, that is, the quaternary carbon dots.

[0023] (2) Preparation of gold nanoparticles:

[0024] Weigh 2g of sapphire gum into 20mL of deionized water, centrifuge at 11000rpm for 6 minutes with a ...

Embodiment 2

[0028] (1) Preparation of quaternary carbon dots:

[0029] Weigh 1.5g of betaine hydrochloride and dissolve it in 30mL of deionized water, then add tris(hydroxymethylaminomethane) with a molar ratio of 1:1, and after it is completely dissolved, add excess isopropanol to obtain a slurry at 65 o Dry under vacuum for 48h. Muffle furnace 250 for dried sticky white matter o After heating at C for 2 hours, 1.2 g of brown solid was obtained, which was added to 100 mL of deionized water. The amount of deionized water used here was 50-100 times the weight of the brown solid, and the formed brown dispersion was precipitated with 150 mL of acetone. , the dosage ratio of acetone and the deionized water in the brown dispersion liquid is 1:1-2:1, and the dark brown powder can be obtained by drying at room temperature, that is, the quaternary carbon dots.

[0030] (2) Preparation of gold nanoparticles:

[0031] Weigh 2.5g of sapphire gum into 30mL of deionized water, centrifuge at 12000rp...

Embodiment 3

[0035] (1) Preparation of quaternary carbon dots:

[0036] Weigh 2g of betaine hydrochloride and dissolve it in 40mL of deionized water, then add tris(hydroxymethylaminomethane) with a molar ratio of 1:1, after it is completely dissolved, add excess isopropanol, and the obtained slurry is at 70 o Dry under vacuum at C for 48h. Muffle furnace 250 for dried sticky white matter o After heating at C for 2 hours, 1.4 g of brown solid was obtained, which was added to 90 mL of deionized water. The amount of deionized water used here was 50-100 times the weight of the brown solid, and the formed brown dispersion was precipitated with 120 mL of acetone, The dosage ratio of acetone and deionized water in the brown dispersion liquid is 1:1-2:1, and the dark brown powder can be obtained by drying at room temperature, that is, the quaternary carbon dots.

[0037] (2) Preparation of gold nanoparticles:

[0038] Weigh 2.2g of sapphire gum into 35mL of deionized water, centrifuge at 10,000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com