Method for preparing air purification material from microporous medium through catalytic oxidation and air purification material

A technology of air purification materials and microporous media, applied in the field of air purification, can solve the problems of lack of good visual experience, slow purification rate, and low purification rate, and achieve good air purification performance and thorough purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

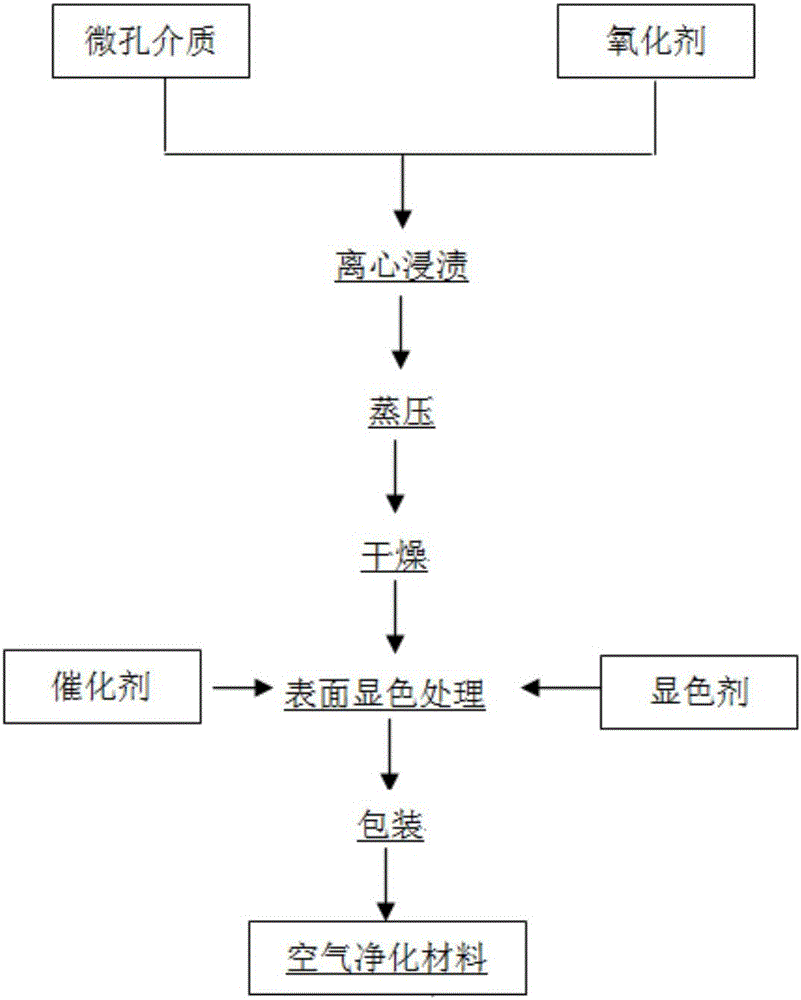

Method used

Image

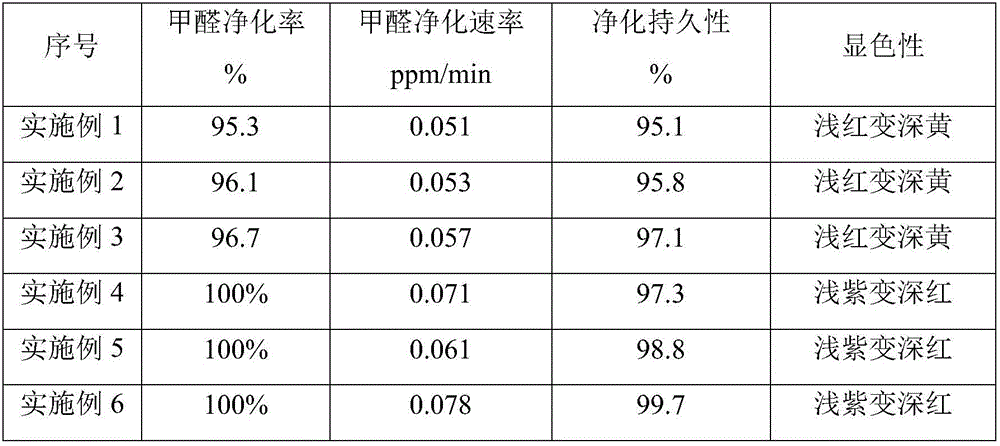

Examples

Embodiment 1

[0029] A kind of air purification material, it is prepared by following method:

[0030] 30 kilograms of activated carbon and 100 kilograms of calcium peroxide solution with a concentration of 1.8wt% were put into a centrifuge, impregnated with a centrifugal speed of 50 r / min for 8 hours, and then autoclaved in an autoclave with a saturated vapor pressure of 0.6 MPa , autoclave for 12 hours, after natural drying, put the activated carbon dry particles loaded with oxidant in a rolling polisher for polishing, and use a spray gun to compound 1 kg of methyl orange, 2 kg of water and 0.5 kg of titanium dioxide photocatalyst to obtain The spraying liquid is evenly sprayed on the surface of the dry particles, and the air purification material is obtained after spraying.

Embodiment 2

[0032] A kind of air purification material, it is prepared by following method:

[0033] 30 kilograms of pure diatoms and 100 kilograms of sodium percarbonate solution with a concentration of 1.8wt% were put into a centrifuge, immersed for 8 hours at a centrifugal speed of 50 r / min, and then autoclaved in an autoclave with a saturated vapor pressure of 0.6 MPa, autoclaved for 12 hours, after natural drying, the pure dry diatom particles loaded with oxidants are placed in a rolling polisher for polishing. While polishing, 1 kg of methylene blue, 2 kg of water and 0.5 kg of titanium dioxide are mixed with a spray gun. The spray liquid obtained by compounding the photocatalyst is uniformly sprayed on the surface of the dry particles, and the air purification material is obtained after spraying.

Embodiment 3

[0035] A kind of air purification material, it is prepared by following method:

[0036] 30 kilograms of nano-mineral crystals and 100 kilograms of potassium persulfate solution with a concentration of 1.8wt% were put into a centrifuge, impregnated for 8 hours at a centrifugal speed of 50 r / min, and then autoclaved in an autoclave with a saturated vapor pressure of 0.6 MPa, autoclaved for 12 hours, after natural drying, the nano-mineral dry particles loaded with oxidant are placed in a rolling polisher for polishing, while polishing, 1 kg of methyl orange, 2 kg of clear water and 0.5 kg of The spray liquid obtained by compounding the vanadium oxide photocatalyst is uniformly sprayed on the surface of the dry particles, and the air purification material is obtained after spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com