Titanium dioxide-based photocatalytic material selectively modified by noble metal nanoparticles and its preparation method and application

A photocatalytic material, titanium dioxide technology, applied in the field of solar energy utilization and environmental protection, can solve the problems of low photocatalytic reduction efficiency and low solar light energy capture efficiency, achieve high photocatalytic reduction activity, simple process flow, and avoid self-forming. nuclear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is the preparation of nano-scale titanium dioxide crystals with surface-optimized growth, and the specific process is as follows:

[0049] First, dissolve 1.6g of titanium tetrafluoride in 400mL of tert-butanol solution to obtain a light yellow clear reaction solution; secondly, transfer the resulting solution into a polytetrafluoroethylene inner container, seal it with an autoclave outer container, and The reaction was incubated at ℃ for 72 hours to generate a suspension containing surface-optimized titanium dioxide crystals; finally, the resulting suspension was centrifuged, and the obtained powder was alternately washed 8 times with deionized water and absolute ethanol, and dried at 60 After drying at ℃ for 10 h, it was ground for later use.

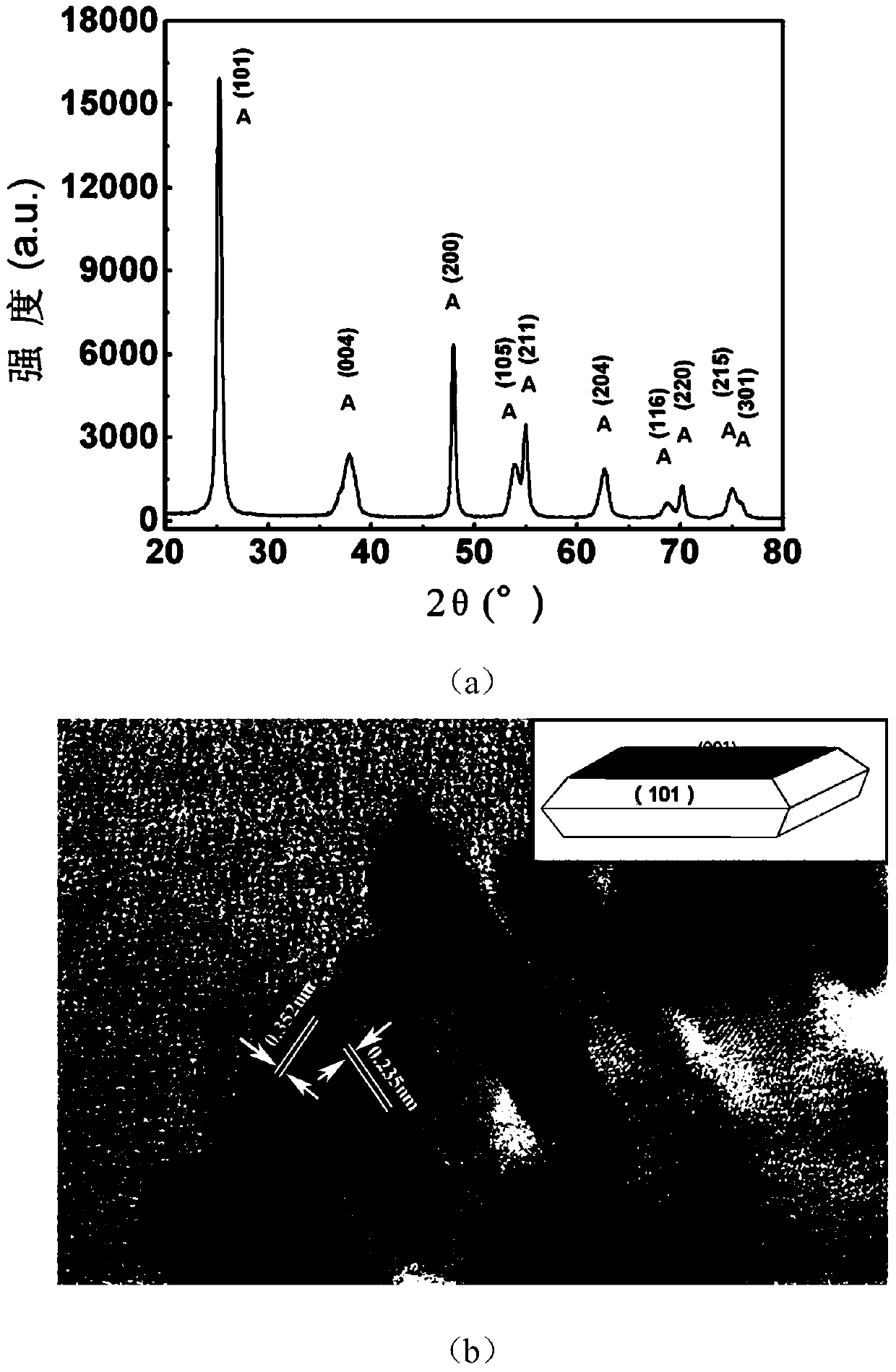

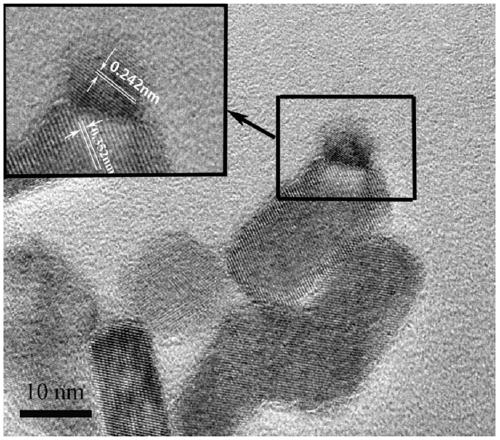

[0050] The powder obtained in this embodiment is the titanium dioxide crystal grown on the surface, figure 1 (a) is the XRD pattern of the crystal, it can be seen that it is an anatase phase titanium dioxide cr...

Embodiment 2

[0052] This embodiment is the preparation of titanium dioxide-based photocatalytic materials selectively modified by silver nanoparticles, and the specific process is as follows:

[0053] 1) Ultrasonic disperse 50 mg of the powder obtained in Example 1 in 5 mL of absolute ethanol to obtain a suspension of titanium dioxide. Use a spin coater to coat 1 mL of the suspension on a quartz plate to form a thin film and dry it at 60° C. for 10 h for use.

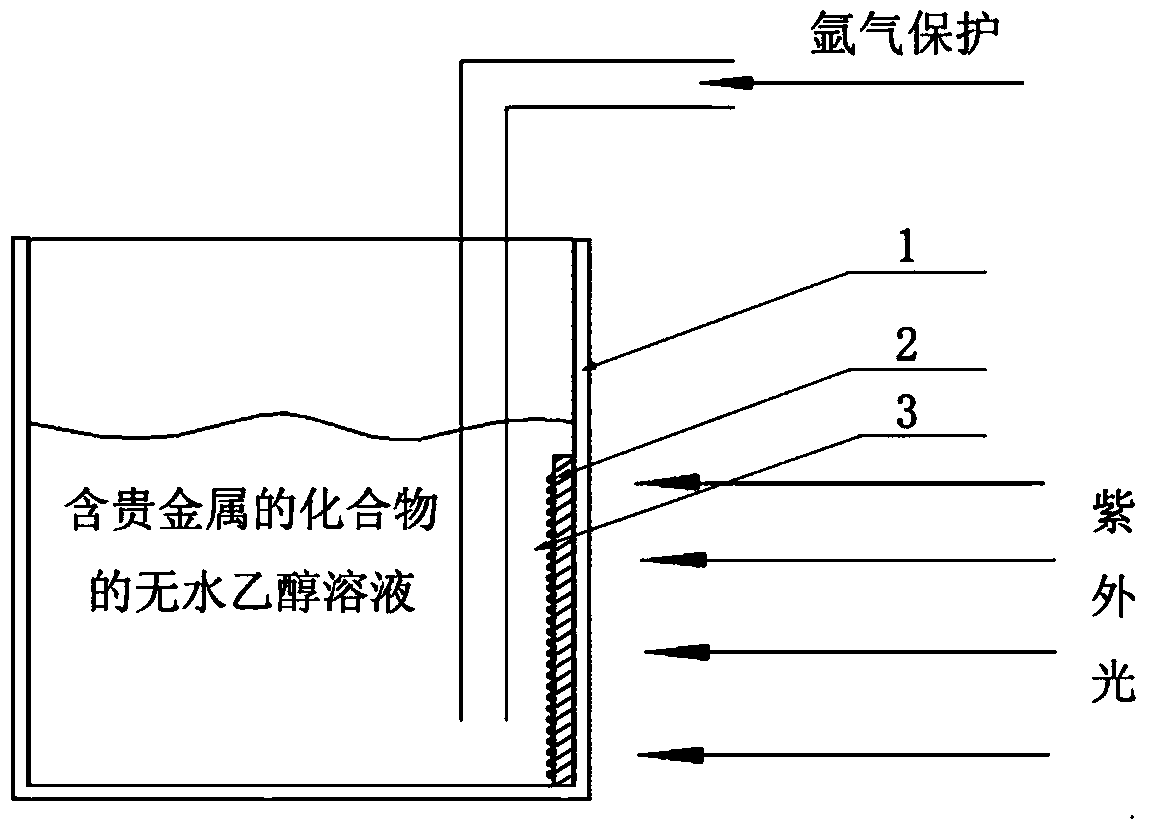

[0054] 2) the quartz plate of the coating film obtained in step 1) is fixed on one side of the self-made reaction tank, and the dehydrated ethanol solution of 100mL silver nitrate is added in the reaction tank (Ag in the solution + Concentration is 10 -4 mol / L), high-purity argon was passed into the solution for half an hour in advance to blow oxygen and a protective atmosphere was maintained during the reaction process, and the light intensity was placed at 5mW / cm 2 The photodeposition reaction was carried out under ultraviolet li...

Embodiment 3

[0062] This example is the preparation of a micron-sized titanium dioxide-based photocatalytic material selectively modified by gold nanoparticles, and the specific process is as follows:

[0063] 1) Preparation of micron-scale surface-optimized titanium dioxide crystals, the process is as follows:

[0064] First, dissolve 0.32g of titanyl sulfate and 1.5mL of 40% hydrofluoric acid in 400mL of secondary deionized water to obtain a light yellow clear reaction solution; secondly, transfer the resulting solution into a polytetrafluoroethylene liner, and use an autoclave to The outer tank is well sealed, and the temperature is kept at 180 °C for 2 hours to generate a suspension containing titanium dioxide crystals grown on the surface; finally, the obtained suspension is centrifuged, and the obtained product is alternately washed with deionized water and absolute ethanol twice. powder 5 times, and after drying at 60°C for 10 h, grind it for later use.

[0065] 2) Ultrasonic dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com