Mineral processing process for recycling barium carbonate from baric carbonate ore

A carbonate ore and process technology, applied in the field of mineral processing, can solve the problems of low barium carbonate content in barium-containing carbonate ore, unsatisfactory barium carbonate grade and recovery rate in concentrates, etc., so as to improve the beneficiation efficiency and avoid roasting. It is not conducive to the effect of protecting the environment and reducing economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

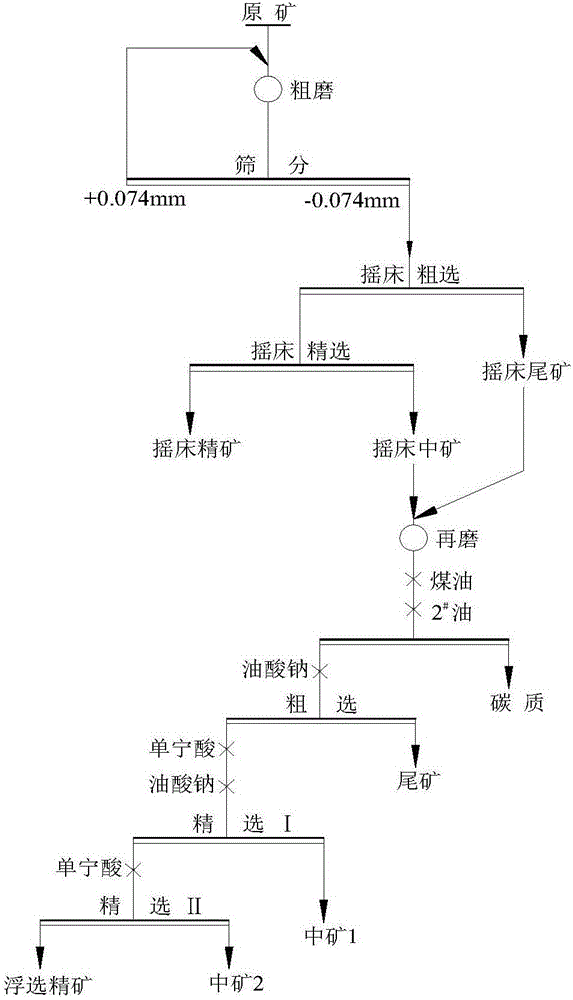

[0045] A kind of beneficiation process of barium carbonate ore, its technological process sees figure 1 ; The main mineral composition of the barium-containing carbonate ore that adopts wherein: witherite content is 45.53wt%, barite content is 15.96wt%, waltzite and barite content are all less than 1% (due to content less , the specific value cannot be measured), quartz 17.56%, calcite 7.47%, dolomite 11.82%, pyrite and organic matter are all less than 1% (due to the small content, the specific value cannot be measured); phase analysis shows that the Barium-containing carbonate ores are mainly witherite and barium calcite, and also contain impurity minerals quartz, calcite and a small amount of dolomite and barite; the content of barium carbonate in the raw ore is 56.85% (the barium carbonate in the raw ore comes from Witherite is also derived from the decomposition of other barium-containing minerals such as barite and sentinite), and its beneficiation process includes the fo...

Embodiment 2

[0055] A beneficiation process of barium-containing carbonate ore; the main mineral composition of the barium-containing carbonate ore used in it is: witherite content of 45.53wt%, barium calcite content of 15.96wt%, sendonite and barite The stone content is less than 1% (the specific value cannot be measured due to the small content), quartz 17.56%, calcite 7.47%, dolomite 11.82%, pyrite and organic matter are all less than 1% (due to the small content, it cannot be measured) specific value); phase analysis shows that the barium-containing carbonate ore is mainly based on witherite and barite, and also contains impurity minerals quartz, calcite and a small amount of dolomite and barite; after determination, the ore barium carbonate The content is 56.85% (raw ore barium carbonate is derived from witherite, and also from the decomposition of other barium-containing minerals such as barite and sendonite), and its beneficiation process includes the following steps:

[0056] 1) Co...

Embodiment 3

[0065] A beneficiation process for barium-containing carbonate ore, wherein the main mineral composition of the barium-containing carbonate ore is: witherite content of 45.53wt%, barium calcite content of 15.96wt%, sendonite and barite The stone content is less than 1% (the specific value cannot be measured due to the small content), quartz 17.56%, calcite 7.47%, dolomite 11.82%, pyrite and organic matter are all less than 1% (due to the small content, it cannot be measured) specific value); phase analysis shows that the barium-containing carbonate ore is mainly based on witherite and barite, and also contains impurity minerals quartz, calcite and a small amount of dolomite and barite; after determination, the ore barium carbonate The content is 56.85% (raw ore barium carbonate is derived from witherite, and also from the decomposition of other barium-containing minerals such as barite and sendonite), and its beneficiation process includes the following steps:

[0066] 1) Coar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com