Hard alloy and preparation method thereof

A cemented carbide, cubic phase technology, applied in the field of alloys, can solve the problems of limited wide application, can not take into account the toughness, wear resistance and hardness at the same time, to improve the strength and wear resistance, good toughness, save the cost of mold manufacturing and the effect of machining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

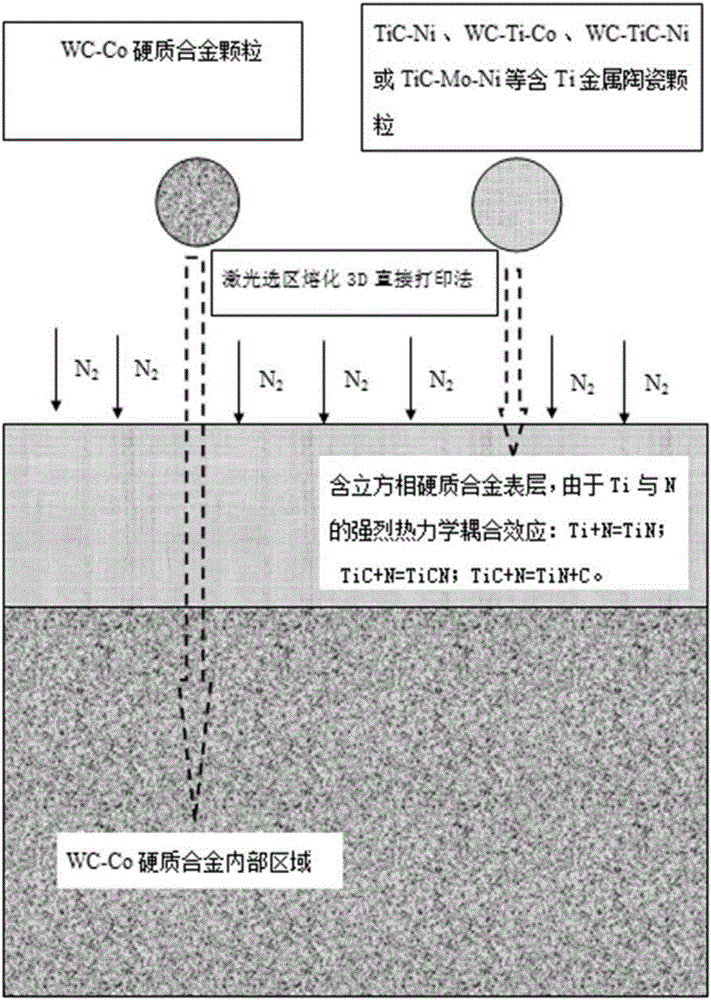

[0040] The present invention provides a kind of preparation method of cemented carbide in the above technical scheme, comprising:

[0041] 3D direct printing of Ti-containing cermet particles by laser selective melting to form a hard alloy surface layer;

[0042] On the surface of the cemented carbide surface, WC-Co cemented carbide particles are 3D directly printed by laser selective melting to form a cemented carbide core;

[0043]On the surface of the hard alloy core, the Ti-containing cermet particles are subjected to laser selective melting and 3D direct printing to form a hard alloy surface layer to obtain a hard alloy.

[0044] In the present invention, the composition of the Ti-containing cermet particles is consistent with the composition of the Ti-containing cermet in the above technical solution, and will not be repeated here. In the present invention, the particle size of the Ti-containing cermet particles is preferably 20-150 μm, more preferably 30-120 μm, and mo...

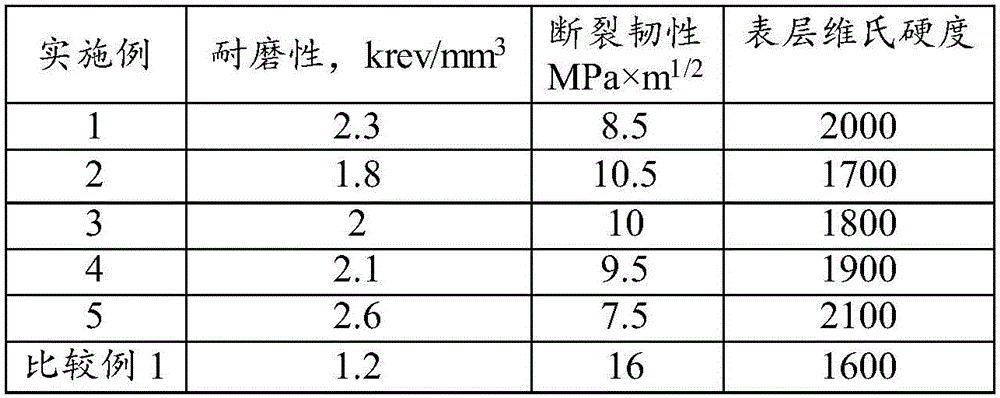

Embodiment 1

[0077] 1) Prepare WC-12Co spherical cemented carbide particles according to the following method:

[0078] Mix Co, WC and paraffin to obtain a mixture; wet mill the mixture at a ball milling speed of 200r / min for 48 hours, dry at 60°C, sieve, and granulate; dewaxing at 1200°C for 2 hours, and then sintering under vacuum at 1200°C to obtain spherical powder particles of WC-12Co. The WC-12Co spherical cemented carbide particles prepared in Example 1 of the present invention have a particle size of 50 μm and a composition of 88 wt.% WC and 12 wt.% Co, wherein the particle size of WC is 100 nm.

[0079] 2) Prepare TiC-20Ni cermet particles according to the following method:

[0080] TiC and Ni and 2wt.% paraffin were mixed to obtain a mixture; the mixture was wet-milled at a ball milling speed of 200r / min for 48 hours, dried at 60°C, sieved, and granulated; Dewaxing is performed at 400° C. for 2 hours in hydrogen, and then sintered at 1200° C. under vacuum to obtain TiC-20Ni sph...

Embodiment 2

[0087] 1) Prepare WC-12Co spherical cemented carbide particles according to the following method:

[0088] Mix Co, WC and paraffin to obtain a mixture; wet mill the mixture at a ball milling speed of 200r / min for 48 hours, dry at 60°C, sieve, and granulate; dewaxing at 1200°C for 2 hours, and then sintering under vacuum at 1200°C to obtain spherical cemented carbide particles of WC-12Co. The WC-12Co spherical cemented carbide particles prepared in Example 2 of the present invention have a particle size of 50 μm and a composition of 88 wt.% WC and 12 wt.% Co, wherein the particle size of WC is 100 nm.

[0089] 2) Prepare WC-30Ti-10Co cermet particles according to the following method:

[0090] WC, Ti, Co and 2wt.% paraffin were mixed to obtain a mixture; the mixture was wet milled at a ball milling speed of 200r / min for 48 hours, dried at 60°C, sieved, and granulated; the obtained balls were The particles were dewaxed in hydrogen at 400°C for 2 hours, and then sintered at 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tile thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com