Electrode wire for unidirectional wire electric discharge machining and preparation method thereof

An electrode wire and electric spark technology is applied in the field of electrode wire for unidirectional wire EDM and its preparation. Advanced problems, to achieve the effect of rapid discharge cutting, shortening the ignition delay time, and optimizing the discharge energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

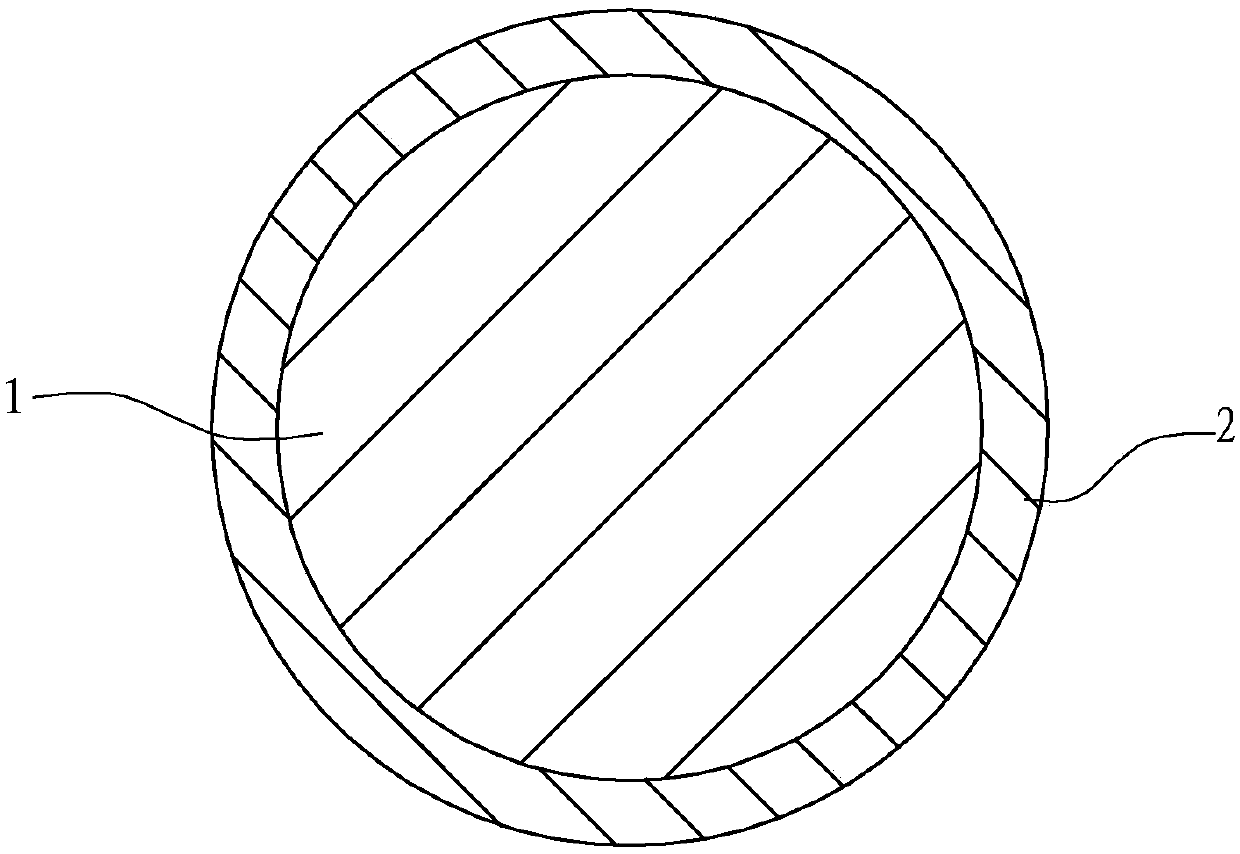

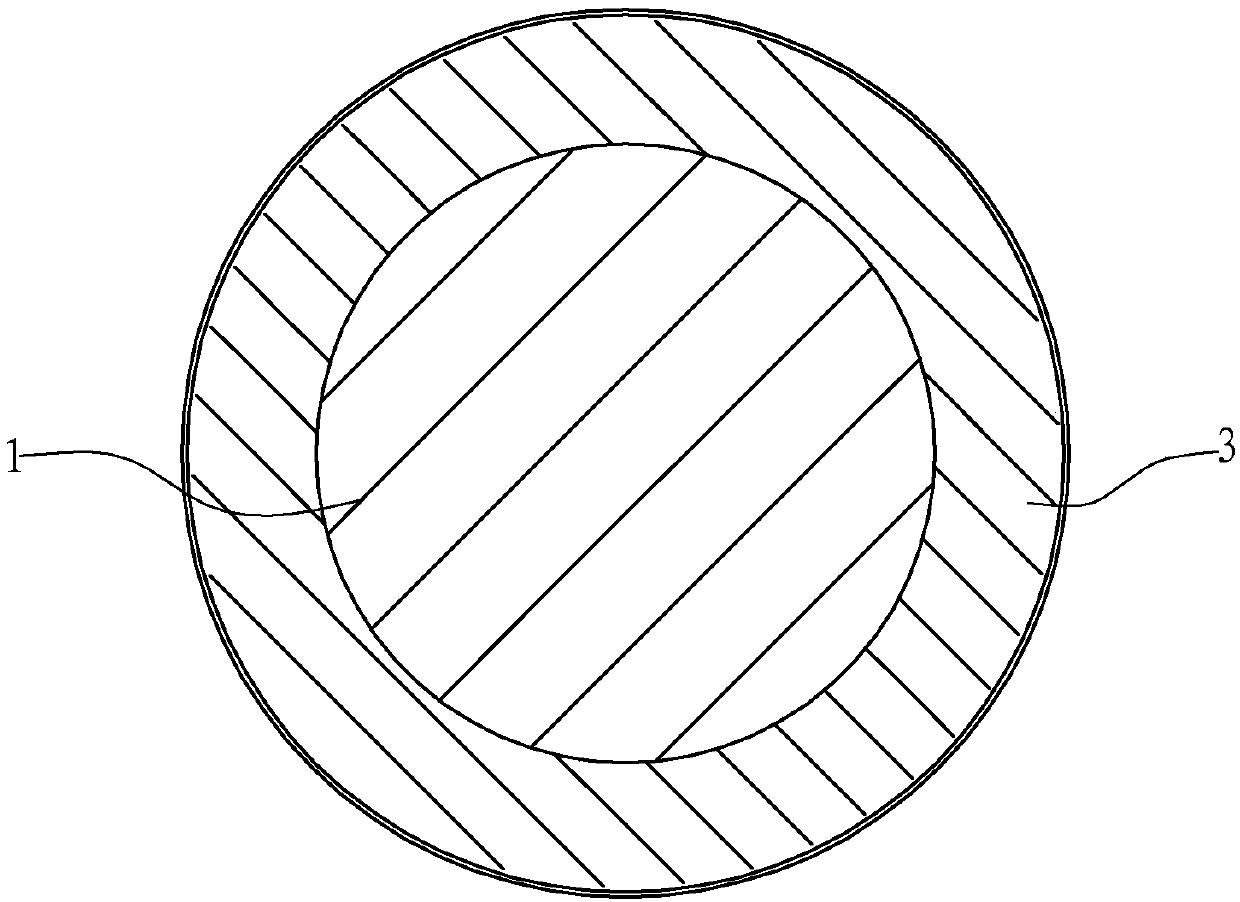

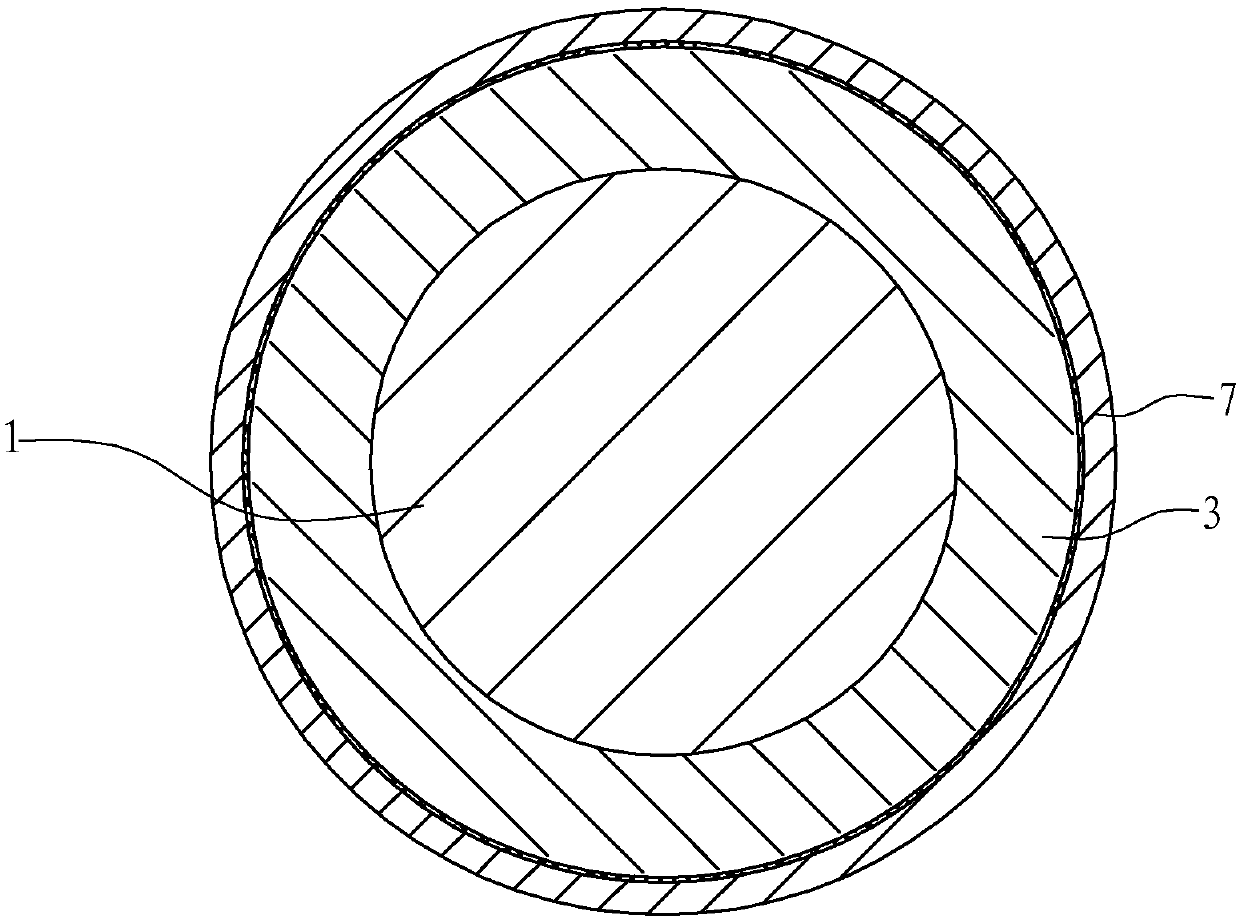

[0033] Take the copper-zinc alloy required for the preparation of the core material 1 and draw and process it into a bus bar with a diameter of 0.6 mm. The bus bar is subjected to degreasing-acid washing-water washing-galvanizing treatment, and the thickness of the zinc coating 2 is 5um to obtain the first wire billet (such as figure 1 shown), where the electroplating current is 1500A and the voltage is 150V. Carry out alloying heat treatment to the first wire billet obtained above, temperature is 390 ℃, heat treatment time is 8h, forms fast discharge cutting layer 3 on core material 1, makes second wire billet (such as figure 2 shown). Carry out polishing pretreatment to the second wire billet obtained above, the processing rate is 5%, carry out degreasing-pickling-washing-galvanizing treatment after polishing pretreatment, the thickness of galvanized layer 7 is 1um, makes the third wire billet (such as image 3 Shown), wherein, the electroplating current is 1000A, and the...

Embodiment 2

[0036] Take the copper-zinc alloy required for the preparation of the core material and stretch it into a bus bar with a diameter of 1.0mm, and then perform degreasing-pickling-water washing-galvanizing treatment on the bus bar, the thickness of the zinc coating is 10um, and the first wire blank is obtained. Among them, the electroplating current is 2000A, and the voltage is 180V. Alloying heat treatment is carried out on the first wire billet prepared above, the temperature is 400° C., and the heat treatment time is 2-10 hours, a fast discharge cutting layer is formed on the core material, and the second wire billet is obtained. Carry out polishing pretreatment on the second wire billet obtained above, the processing rate is 10%, after the polishing pretreatment, carry out degreasing-pickling-water washing-galvanizing treatment, the thickness of the zinc coating is 3um, and the third wire billet is obtained, wherein, The electroplating current is 1500A, and the voltage is 150...

Embodiment 3

[0039] The copper-zinc alloy required for the preparation of the core material is stretched and processed into a bus bar with a diameter of 1.2mm, and the bus bar is subjected to degreasing-acid washing-water washing-galvanizing treatment, and the thickness of the zinc coating is 15um to obtain the first wire blank. Among them, the electroplating current is 2500A, and the voltage is 220V. Alloying heat treatment is carried out on the first wire billet prepared above, the temperature is 440° C., the heat treatment time is 10 h, a fast discharge cutting layer is formed on the core material, and the second wire billet is obtained. Carry out polishing pretreatment on the second wire billet obtained above, the processing rate is 15%, after polishing pretreatment, carry out degreasing-pickling-water washing-galvanizing treatment, the thickness of the zinc coating is 10um, and the third wire billet is obtained, wherein, The electroplating current is 2000A, and the voltage is 220V. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com