Nonconventional low-temperature gas shielded laser welding method

A low-temperature gas, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of discontinuous forming, welding pores, unstable welding process, etc. The effect of increasing the cooling rate and reducing welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

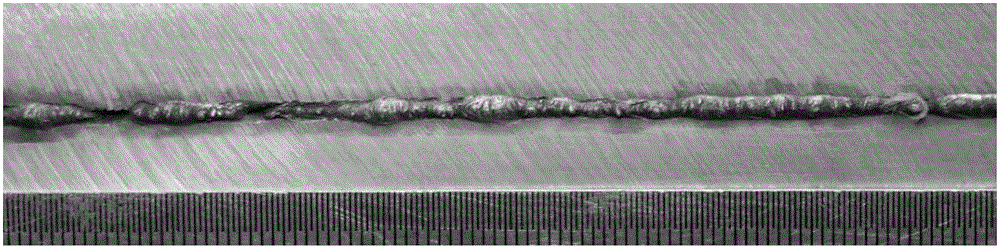

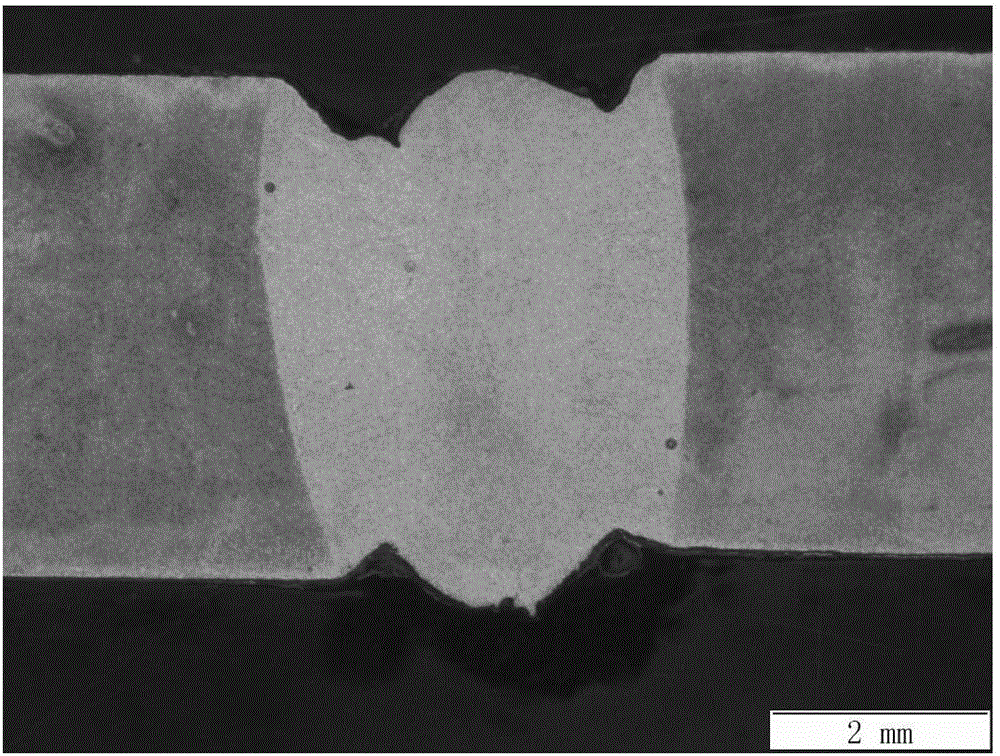

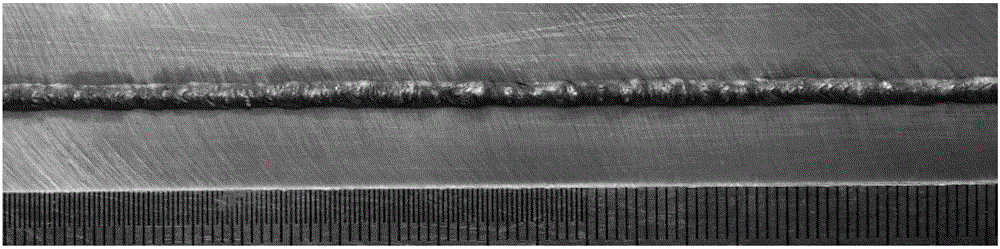

[0026] Specific embodiment one: a kind of unconventional low temperature gas shielded laser welding method of this embodiment, it is carried out according to the following steps:

[0027] Step 1: Before welding, process the parts to be welded into V-shaped grooves, U-shaped grooves or Y-shaped grooves, and grind and clean the processed grooves and the surfaces on both sides. After cleaning, the workpiece to be welded is fixed on the welding fixture;

[0028] Step 2: Use the fixture to rigidly fix the laser head and the wire feeding mechanism;

[0029] Step 3: Set welding process parameters:

[0030] The welding speed is 0.5~5m / min, the laser power is 2000~6000W, the defocus is -3~+3, if the welding wire is filled, the wire feeding speed is 0.2~1.0m / min; the shielding gas adopts Ar gas and He gas Or the mixed gas of the two, the protective gas flow rate is 5-20L / min, and the protective gas temperature is -30℃~-160℃;

[0031] Step 4: In the actual welding process, the robot i...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment is different from Embodiment 1 in that: the workpiece to be welded is steel, aluminum or titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment is different from Embodiment 1 in that: the temperature of the shielding gas is -50°C to -160°C. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com