Graphene transfer method

A graphene and melting point technology, applied in the field of material science, can solve the problems of long time consumption, polymer residues, affecting the performance and application of graphene, and achieve the effect of simple conditions and overcoming uncontrollability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

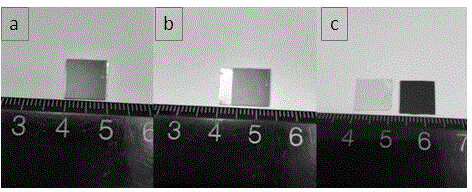

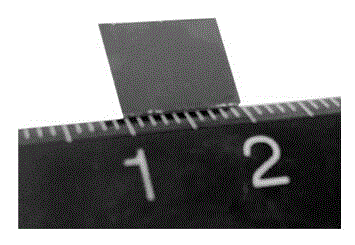

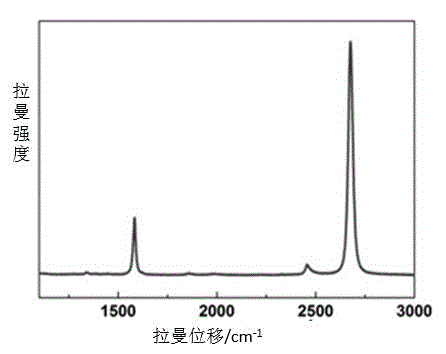

[0047] Embodiment 1, fast slip transfer graphene

[0048] 1) Choose a thickness of 50 μm and a size of 1×1 cm 2 The tungsten sheet was used as the growth substrate (metal substrate), and ultrasonicated in acetone, ethanol, and ultrapure water for 20 minutes each.

[0049] 2) Place 20 mg gallium on a tungsten sheet under heating at 40 °C and make it adhere to it.

[0050] 3) In hydrogen gas (flow rate of 30 sccm) and argon gas (flow rate of 300 sccm), the growth substrate obtained in step 2) was heated from room temperature to the growth temperature of 1020 °C for 35 minutes in a tube furnace, and then the Carbon source methane (flow rate is 10 sccm), growth time is 70 min, and then cool down naturally, when the temperature drops to 700 °C, open the lid to cool down naturally, when the temperature is lower than 200 °C, turn off the hydrogen, when the temperature is lower than 100 °C Turn off the protective gas argon at °C, take out the sample, that is, obtain the single-layer...

Embodiment 2

[0054] Embodiment 2, fast slip transfer graphene

[0055] 1) Choose a thickness of 50 μm and a size of 1×1 cm 2 The tungsten sheet was used as the growth substrate (metal substrate), and ultrasonicated in acetone, ethanol, and ultrapure water for 20 minutes each.

[0056] 2) Place 20mg of gallium on a tungsten sheet under heating at 40 °C and make it adhere to it.

[0057] 3) In hydrogen gas (flow rate of 30 sccm) and argon gas (flow rate of 300 sccm), the growth substrate obtained in step 2) was heated from room temperature to the growth temperature of 1020 °C for 35 minutes in a tube furnace, and then the Carbon source methane (flow rate is 10 sccm), growth time is 70 min, and then cool down naturally, when the temperature drops to 700 °C, open the lid to cool down naturally, when the temperature is lower than 200 °C, turn off the hydrogen, when the temperature is lower than 100 °C Turn off the protective gas argon at °C, take out the sample, that is, obtain the single-lay...

Embodiment 3

[0060] Embodiment 3, fast slip transfer graphene

[0061] 1) Choose a thickness of 50 μm and a size of 1×1 cm 2 The molybdenum foil used as the growth substrate (metal substrate) was ultrasonicated in acetone, ethanol, and ultrapure water for 20 minutes each.

[0062] 2) Place 10 mg gallium on the molybdenum foil under heating at 40 °C and make it adhere to it.

[0063] 3) In hydrogen gas (flow rate of 30 sccm) and argon gas (flow rate of 250 sccm), the growth substrate obtained in step 2) was heated from room temperature to the growth temperature of 800 °C for 35 min in a tube furnace, and carbon Source methane (flow rate of 10 sccm), grow for 30 min, and then cool down naturally. When the temperature drops to 700 °C, open the lid to cool down naturally. When the temperature is lower than 200 °C, turn off the hydrogen, and when the temperature is lower than 100 °C At C, the protective gas argon is turned off, and the sample is taken out, that is, the single-layer graphene p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com