Preparation method of silica powder and silica powder

A technology of silica powder and silica, which is applied in the direction of silica, silica, etc., can solve problems such as harsh reaction conditions, and achieve the effects of adjustable pore structure, high dispersion, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

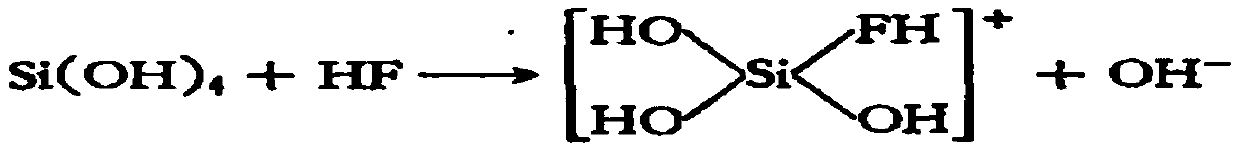

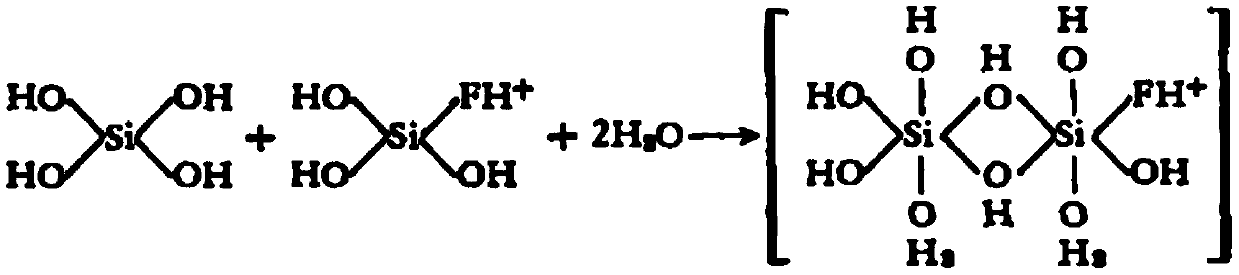

Method used

Image

Examples

example 1

[0032] Experimental procedure without adding surfactant:

[0033] First add deionized water into the reactor with a stirring device, then dissolve a certain amount of KF and add it into the reactor, start stirring, heat the above-mentioned fluorine-containing aqueous solution to the required temperature, and then use a metering pump to pump a certain amount of KF into the reactor. Silicon tetrachloride is added in the reactor at a certain speed, and the stirring is continued. After the reaction is over, the silica precipitate is filtered and washed by a centrifuge. After no chlorine ions and fluoride ions are detected in the filtrate, the washing is stopped and the The silica filter cake is put into an oven for drying to obtain a silica powder product with well-developed medium and large pores.

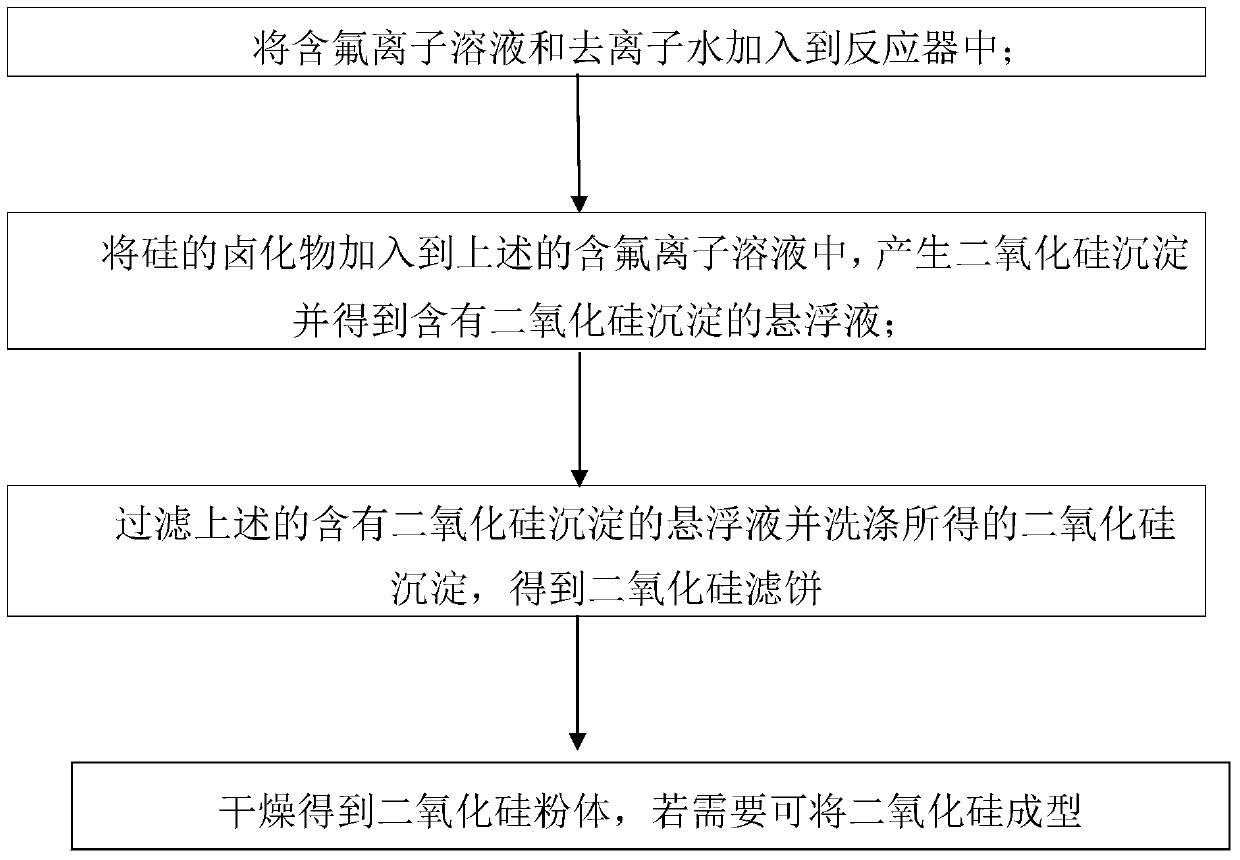

[0034] For the flow chart of the test, see figure 1 shown.

example 2

[0036] Experimental steps for adding surfactants:

[0037] First add deionized water, polyvinylpyrrolidone and KF into the reactor with stirring device, start stirring, heat the above-mentioned fluorine-containing aqueous solution containing surfactant to the required temperature, and then use a metering pump to pump a certain amount of tetrachloride Silicon is added to the reactor at a certain speed, and the stirring is continued. After the reaction is completed, the silica precipitate is filtered and washed with a plate and frame filter press. When no chloride ions and fluoride ions are detected in the filtrate, the washing is stopped. The method of spray drying dries the silica filter cake to obtain a silica powder product with high dispersion and well-developed micropores.

[0038] Specific example 1:

[0039] Add 1L of deionized water into a 2L tank reactor, dissolve 20g of KF in deionized water, add it to the reactor, stir and heat up to 40°C, and add silicon tetrachlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com