Denitriding microbial nest based on basalt fiber filling materials and culture method thereof

A basalt fiber and microbial technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited anoxic anaerobic environment, impact of granular sludge, and easy clogging of separation membranes and other problems, to achieve the effect of rich bacterial flora, low cost, and large effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

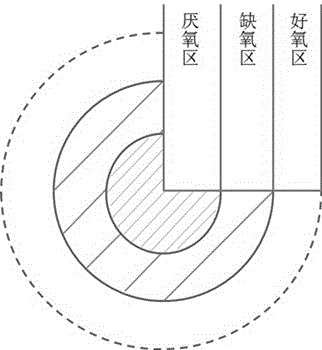

[0029] Embodiment 1: as figure 1 , 2 A kind of denitrification microbial nest based on basalt fiber filler shown in and 3, described denitrification microbial nest is a multilayer spherical or spherical structure, and described denitrification microbial nest includes anaerobic layer, Anoxic layer and aerobic layer, etc., the denitrification microbial nest is attached to basalt fiber filler, the anaerobic layer is composed of activated sludge with anaerobic bacteria attached, and the anoxic layer is composed of The aerobic layer is composed of activated sludge with aerobic bacteria.

[0030] The outer surface of the microbial nest is an aerobic layer, which mainly enriches a large number of nitrifying bacteria for nitrification, and presents a khaki-yellow film layer for aerobic reactions; the middle layer transitioning inward is an anoxic layer, which mainly enriches a large number of denitrifying bacteria for nitrification. Denitrification, which appears as a black or dark ...

Embodiment 2

[0031] Embodiment 2: as Figure 4 As shown, the cultivation reactor of the denitrification microbial nest based on the basalt fiber filler provided by the present invention, the reactor is intermittent operation or continuous flow operation, the bottom of the reactor 1 is provided with a waste water inlet 4, and the reactor The middle part of the reactor 1 is provided with an intermittent operation water outlet 5, and the upper right part of the reactor 1 is provided with a continuous flow mixed liquid outlet 6, and the top of the reactor 1 is provided with a plurality of evenly distributed hanging hooks, and the hanging hooks are vertically A basalt fiber filler 2 is suspended, and the basalt fiber filler 2 is a strip structure, and a plurality of basalt fiber bundles are evenly distributed on the basalt filler 2, and the bottom of the reactor 1 is provided with an aerator 3, and the aerator 3 3 is arranged in the gap between two adjacent basalt fiber fillers 2 .

[0032] Th...

Embodiment 3

[0033] Embodiment 3: as Figure 4 As shown, the basalt fiber bundle of the present invention is composed of multiple basalt fiber monofilaments, the diameter of the basalt fiber monofilament is 7-21 μm, the diameter of the basalt fiber bundle is 10-40 cm, and the adjacent The interval between two basalt fiber bundles is 20-40cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com