A kind of composite ceramic tool material and preparation method thereof

A cutting tool material and composite ceramic technology, applied in the field of ceramic cutting tool materials, can solve the problems of unsatisfactory composite material performance, high manufacturing cost, and many raw material components, and achieve the effects of reducing preparation time, reducing production cost, and excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

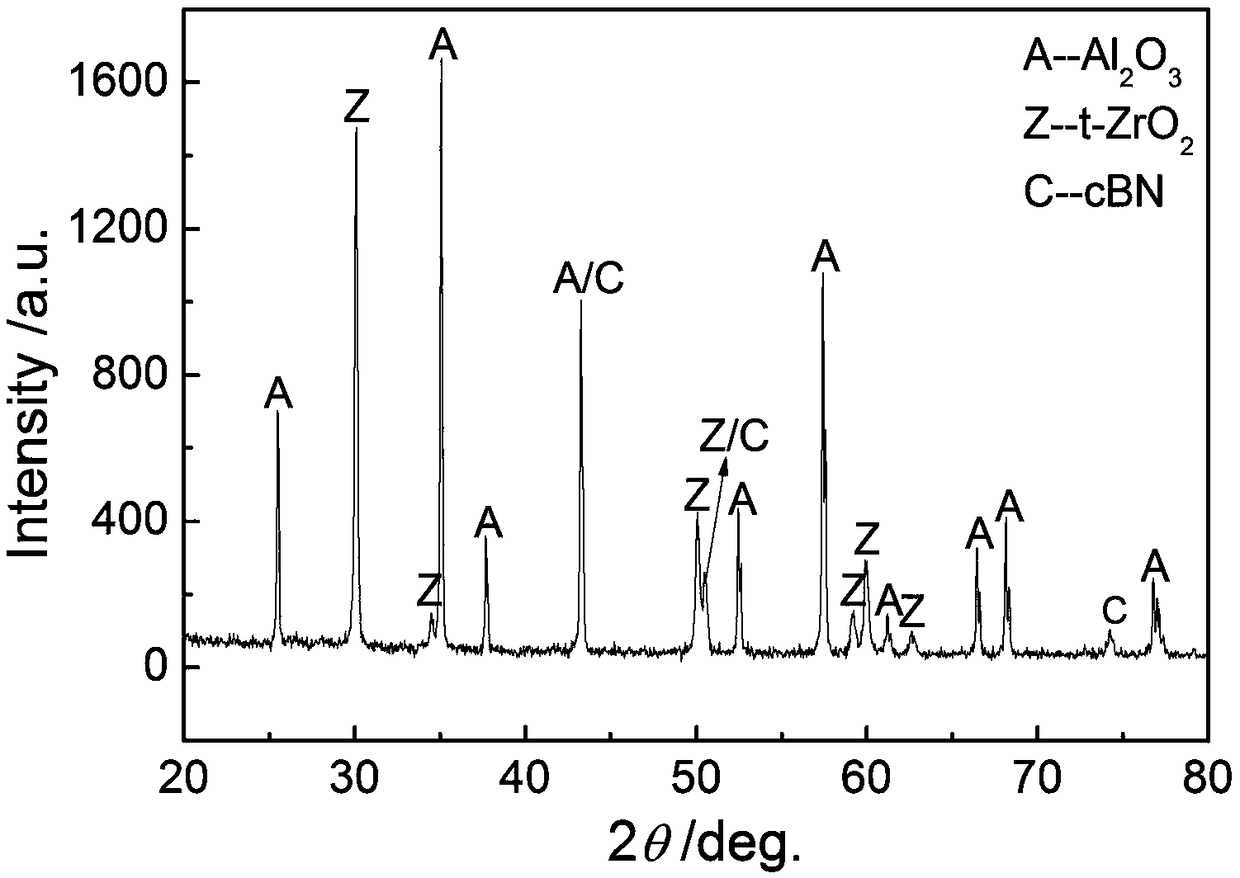

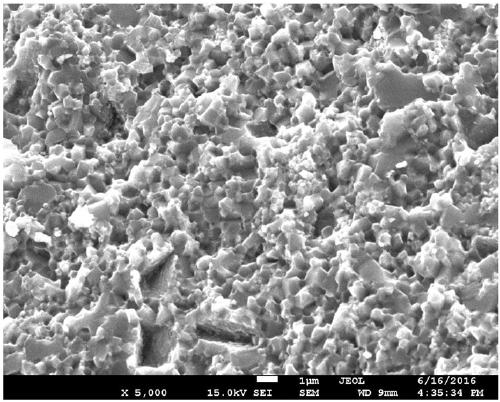

[0042] A kind of composite ceramic tool material, containing composition and its volume percentage is Al 2 o 3 : 85%, ZrO 2 : 10%, cBN: 5%.

[0043] The preparation method of above-mentioned composite ceramic cutter material comprises the following steps:

[0044] Step 1, prepare raw material powder:

[0045] According to the composition of composite ceramic tool material, weigh Al 2 o 3 Powder, Y 2 o 3 Stable ZrO 2 powder and cBN powder; among them, Al 2 o 3 Powder particle size is 0.08~0.15μm; Y 2 o 3 Stable ZrO 2 The particle size of powder is 0.02~0.08μm; the particle size of cBN powder is 1~2um;

[0046] Step 2, configure the dispersant solution:

[0047] Dissolve ammonium citrate and ammonium polyacrylate in water to make a dispersant solution; wherein: ammonium citrate accounts for 0.20% of the mass sum of the powder, and ammonium polyacrylate accounts for 0.05% of the mass sum of the powder; the volume of water is selected according to the preparation ste...

Embodiment 2

[0055] A kind of composite ceramic tool material, containing composition and its volume percentage is Al 2 o 3 : 80%, ZrO 2 : 10%, cBN: 10%.

[0056] The preparation method of above-mentioned composite ceramic cutter material comprises the following steps:

[0057] Step 1, prepare raw material powder:

[0058] According to the composition of composite ceramic tool material, weigh Al 2 o 3 Powder, Y 2 o 3 Stable ZrO 2 powder and cBN powder; among them, Al 2 o 3 Powder particle size is 0.08~0.15μm; Y 2 o 3 Stable ZrO 2 The particle size of powder is 0.02~0.08μm; the particle size of cBN powder is 2~3μm;

[0059] Step 2, configure the dispersant solution:

[0060] Dissolve ammonium citrate and ammonium polyacrylate in water to make a dispersant solution; wherein: ammonium citrate accounts for 0.50% of the mass sum of the powder, and ammonium polyacrylate accounts for 0.15% of the mass sum of the powder; the volume of water is selected according to the preparation st...

Embodiment 3

[0068] A kind of composite ceramic tool material, containing composition and its volume percentage is Al 2 o 3 : 80%, ZrO 2 : 15%, cBN: 5%.

[0069] The preparation method of above-mentioned composite ceramic cutter material comprises the following steps:

[0070] Step 1, prepare raw material powder:

[0071] According to the composition of composite ceramic tool material, weigh Al 2 o 3 Powder, Y 2 o 3 Stable ZrO 2 powder and cBN powder; among them, Al 2 o 3 Powder particle size is 0.08~0.15μm; Y 2 o 3 Stable ZrO 2 The particle size of powder is 0.02~0.08μm; the particle size of cBN powder is 3~5μm;

[0072] Step 2, configure the dispersant solution:

[0073] Ammonium polyacrylate is dissolved in water to make a dispersant solution; wherein: ammonium polyacrylate accounts for 0.70% of the mass sum of the powder; the volume of water is selected according to the calculation of 20% of the solid content of the powder weighed in the preparation step 1.

[0074] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com