A kind of method for preparing dihydrocitronellal

A technology of dihydrocitroninum and malal, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of increasing post-processing steps and costs, and achieve easy control, simple methods, and Avoid the effects of high temperature and pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of iron cobalt n-decoxide

[0047] (1) ferric chloride and n-decyl alcohol that the mol ratio is 1:3 are put into the round-bottomed flask, the flask is placed in an oil bath and heated, reacted at 250 ° C for 8 hours, and distillation under reduced pressure obtains iron n-decyl alcohol;

[0048] (2) the cobalt chloride and n-decanol that the mol ratio is 1:3 are put into the round-bottomed flask, the flask is placed in an oil bath and heated, and reacted at 250 ° C for 8 hours, and distillation under reduced pressure obtains cobalt n-decoxide;

[0049] (3) Ferric n-decoxide and cobalt n-decoxide with a molar ratio of 1:1 are put into a round-bottomed flask, and benzene is used as a solvent, and the reaction time is 12 hours at 280° C., and distillation under reduced pressure is performed to obtain iron cobalt n-decoxide.

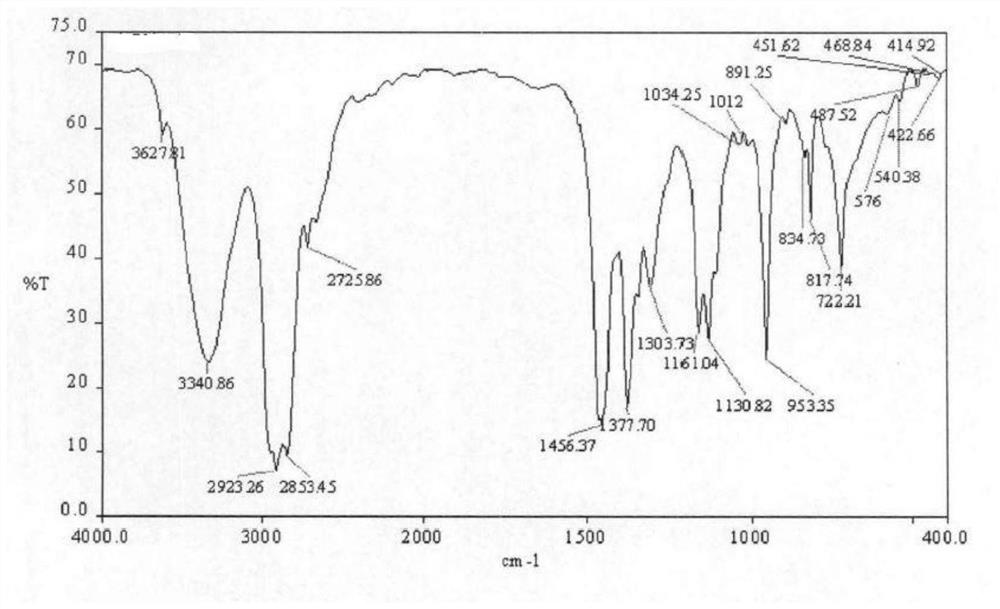

[0050] exist figure 1 In the infrared spectrum of 576cm -1 , 540.38cm -1 , 468.84cm -1 , is the absorption peak of iron c...

Embodiment 1

[0054] A method for preparing dihydrocitronellal, the steps are:

[0055] Under the protection of nitrogen atmosphere, 0.152g iron cobalt n-decoxide, 3.04g (5% nickel loading) nickel activated carbon, 64g methanol and 152.1g citral (acid value 0.05mgKOH / g) were added to the reaction kettle. After 6 times of replacement with nitrogen and the volume content of oxygen reduced to below 10 ppm, heating was started, the temperature of the reaction kettle was raised to 30 °C, the pressure was normal pressure, and the reaction was maintained at the temperature of the kettle for 20 h. After the reaction was completed, the reaction solution was obtained by filtration.

[0056] A small amount of the reaction solution was analyzed by gas chromatography, and the conversion rate of citral was 99.01%, and the selectivity of the main product, dihydrocitronellal, was 98.39%. The conversion rate of methanol is 99.5%, and the selectivity of converting methanol into target by-product formaldehyd...

Embodiment 2

[0059] A method for preparing dihydrocitronellal, the steps are:

[0060] Under the protection of nitrogen atmosphere, 0.304g iron cobalt n-decoxide, 30.42g (5% nickel loading) nickel carbon nanotubes, 110.4g ethanol and 152.1g citral (acid value 0.05mgKOH / g) were added to the reaction kettle. After 6 times of nitrogen replacement, the oxygen volume content dropped below 10 ppm, and then the heating was started, the temperature of the reaction kettle was raised to 40 °C, the pressure was normal pressure, and the reaction was maintained at the kettle temperature for 6 h. After the reaction was completed, the reaction solution was obtained by filtration.

[0061] A small amount of the reaction solution was analyzed by gas chromatography. The conversion rate of citral was 99.24%, and the selectivity of the main product, dihydrocitronellal, was 98.61%. The conversion rate of ethanol is 83.71%, and the selectivity of converting ethanol into the target by-product formaldehyde is 98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com