Bamboo-fungus culture medium and preparing method thereof

A culture medium and technology of bamboo fungus, applied in botany equipment and methods, fertilizers made of biological waste, application, etc., can solve the problems of insufficient nutrients in the later stage of the culture medium, long fruiting time, etc. Mushroom time is short and the effect of improving the quality of Dictyophora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

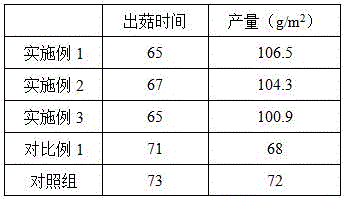

Examples

Embodiment 1

[0021] A bamboo fungus medium, prepared from the following raw materials in parts by weight: 12 parts of bran, 36 parts of bamboo sawdust, 8 parts of bamboo leaves, CaO 2 0.12 parts, 0.3 parts of ascorbic acid, 0.2 parts of phytic acid, 10 parts of soluble starch, 8 parts of chitosan, 0.5 parts of potassium dihydrogen phosphate, 5 parts of oyster powder, 6 parts of saponins extract, 0.3 parts of PVP, rapeseed oil 2 copies;

[0022] The bamboo sawdust is soaked in nutrient solution for 2 hours in advance;

[0023] The nutrient solution contains 3g of calcium stearate lactate, 2g of vitamin B, and 8g of sodium alginate in every 1000ml of water;

[0024] Described acacia extract is that 25 parts of acacia seeds and 18 parts of acacia are added with 300 parts of pure water, heated and boiled for 50 min, filtered, and the filtrate is added with calcium citrate accounting for 0.8% of the filtrate weight, and stirred evenly;

[0025] The culture medium was prepared as follows:

[...

Embodiment 2

[0029] A bamboo fungus culture medium, prepared from the following raw materials in parts by weight: 10 parts of bran, 38 parts of bamboo sawdust, 7 parts of bamboo leaves, CaO 2 0.1 part, 0.33 part of ascorbic acid, 0.1 part of phytic acid, 9 parts of soluble starch, 6 parts of chitosan, 0.7 part of potassium dihydrogen phosphate, 4 parts of oyster powder, 5 parts of saponin extract, 0.3 part of PVP, rapeseed oil 3 copies;

[0030] Described acacia extract is that 23 parts of acacia seeds and 15 parts of acacia are added with 300 parts of pure water, heated and boiled for 50 min, filtered, and the filtrate is added with calcium citrate accounting for 0.8% of the filtrate weight, and stirred evenly;

[0031] The culture medium was prepared as follows:

[0032] (1) After ascorbic acid, phytic acid and soluble starch are stirred evenly, PVP and rapeseed oil are added to the mixed raw materials, stirred evenly and then granulated, then sprayed with saponin extract, sprinkled wit...

Embodiment 3

[0035] A bamboo fungus culture medium, prepared from the following raw materials in parts by weight: 11 parts of bran, 35 parts of bamboo sawdust, 5 parts of bamboo leaves, CaO 2 0.15 parts, 0.36 parts of ascorbic acid, 0.1 parts of phytic acid, 8 parts of soluble starch, 7 parts of chitosan, 0.8 parts of potassium dihydrogen phosphate, 3 parts of oyster powder, 4 parts of saponin extract, PVP, 3 parts of rapeseed oil;

[0036] Described acacia extract is to add 300 parts of pure water in 20 parts of acacia seeds and 20 parts of acacia, heat and boil for 50min, filter, add calcium citrate accounting for 0.8% of the filtrate weight in the filtrate, and stir to get final product;

[0037] The preparation method of the culture medium is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com