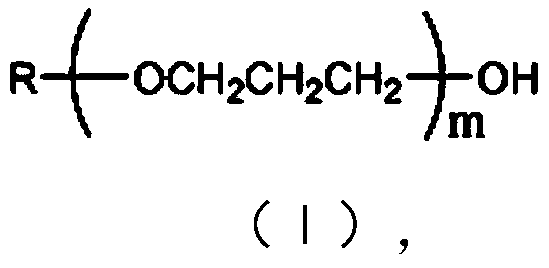

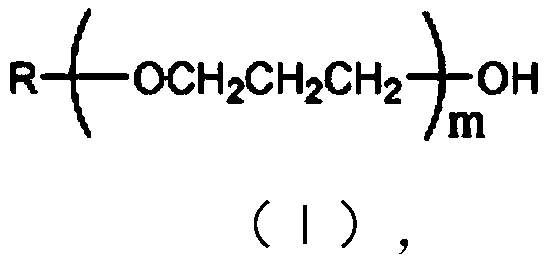

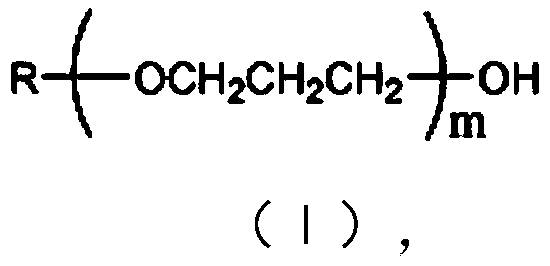

A kind of polyhydroxy PEG macromonomer and preparation method thereof

A macromonomer and polyhydroxyl technology, applied in the field of polyhydroxy PEG macromonomer and its preparation, can solve the problems of large increase in engineering cost and complex synthesis process, and achieve the effects of high cost performance, easy availability of raw materials, and improved water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A kind of embodiment of the preparation method of polyhydroxy PEG macromonomer of the present invention, comprises the following steps:

[0074] (1) In a closed autoclave, replace the air in the reactor with high-purity nitrogen repeatedly twice, inject 1mol of propylene alcohol and 0.2g of catalyst NaOH, raise the temperature of the reactor to 70-85°C, and slowly add 1mol of epoxy Ethane, so that the reaction temperature is controlled within the range of 70 ° C, the pressure in the kettle is controlled at 0.2 MPa, and the amount of ethylene oxide required for dropwise addition is controlled by the decrement method. After the dropwise addition of ethylene oxide is completed, the temperature is controlled At 80°C, the reaction was continued for 5h to obtain an intermediate product with the desired molecular weight.

[0075] (2) Keep the temperature at 80° C., start to slowly add 1 mol of glycidol dropwise, and control the dropwise addition for 1.5 hours. After the dropwi...

Embodiment 2

[0077] A kind of embodiment of the preparation method of polyhydroxy PEG macromonomer of the present invention, comprises the following steps:

[0078] (1) In a closed autoclave, replace the air in the reactor with high-purity nitrogen repeatedly for 3 times, inject 1mol of prenyl alcohol and 0.5g of catalyst potassium hydroxide, raise the temperature of the reactor to 110°C, and start to slowly add 4mol ethylene oxide, so that the reaction temperature is controlled within the range of 115 ° C, the pressure in the kettle is controlled at 0.4 MPa, and the amount of ethylene oxide required for dripping is controlled by the decrement method. After the dropwise addition of ethylene oxide is completed, The temperature was controlled at 110°C, and the reaction was continued for 2 hours to obtain an intermediate product with the desired molecular weight.

[0079] (2) Lower the temperature to 80° C., start to slowly add 2 mol of glycidol dropwise, and control the dropwise addition for...

Embodiment 3

[0081] A kind of embodiment of the preparation method of polyhydroxy PEG macromonomer of the present invention, comprises the following steps:

[0082] (1) In a closed autoclave, replace the air in the reactor with high-purity nitrogen repeatedly twice, inject 1mol of isobutenol and 2g of catalyst potassium carbonate, raise the temperature of the reactor to 115°C, and slowly add 80mol of ethylene oxide dropwise Alkanes, so that the reaction temperature is controlled within the range of 130 °C, the pressure in the kettle is controlled at 0.6MPa, and the amount of ethylene oxide required for dropwise addition is controlled by the decrement method. After the dropwise addition of ethylene oxide is completed, the temperature is controlled at At 120°C, the reaction was continued for 0.5h to obtain an intermediate product with the desired molecular weight.

[0083] (2) Lower the temperature to 80° C., start to slowly add 3 mol of glycidol dropwise, and control the dropwise addition f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com