Waterborne colorful luminous paint and preparation method thereof

A luminous paint and colorful technology, applied in the paint field, can solve the problems of lack of exterior wall decoration function and light limitation, and achieve the effect of convenient construction, strong decoration, and simple raw material methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

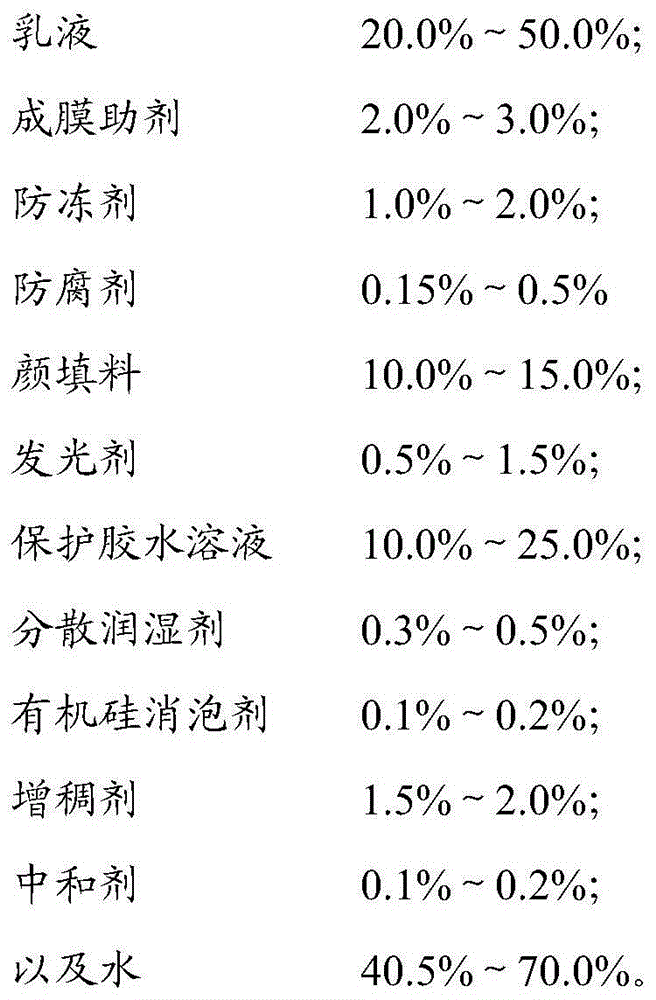

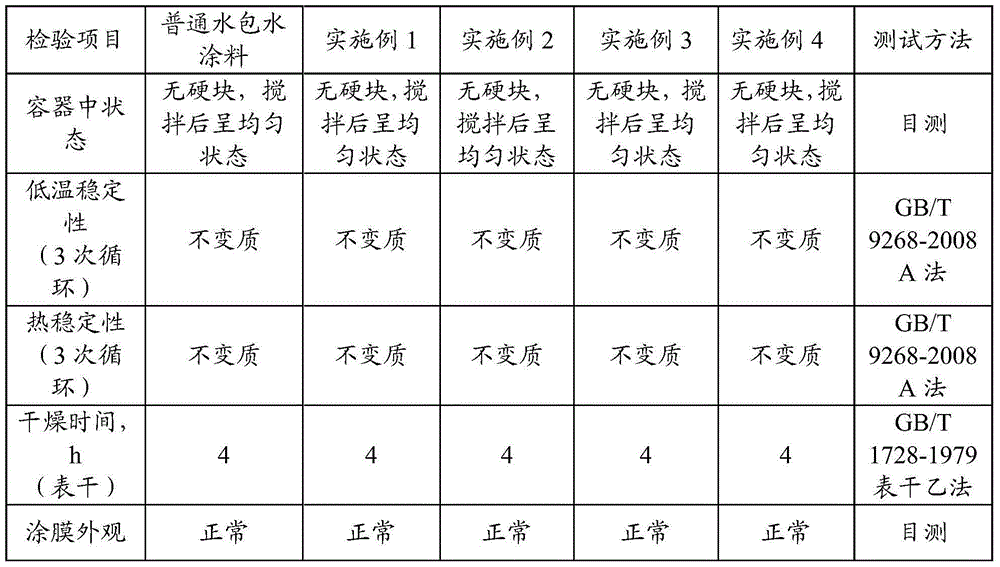

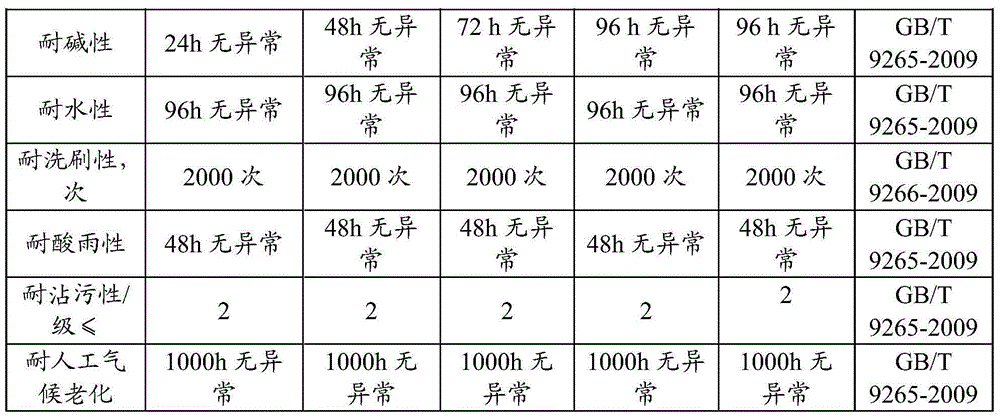

[0044] The raw material formula (wt%) of water-based colorful luminescent paint sees the following table 1

[0045] The raw material formula (wt %) of the waterborne multicolored luminescent paint of table 1 embodiment 1

[0046] base paint

[0047] Deionized water 50.5% Silicone defoamer 0.2% Dispersant 0.3% 30,000 cellulose 0.9% Neutralizer 0.2% Pigments 15% lotion 20% thickener 0.4% luminescent agent 0.5% protective glue solution 12%

[0048] Finished color grain

[0049] protective glue solution 40% base paint 60%

[0050] Finished paint

[0051] Deionized water 37.7% Silicone acrylic emulsion 30% Coalescent 2% Finished Particles 30% thickener 0.3%

[0052] The preparation method of water-based colorful luminous paint, it may further comprise the steps:

[0053] According to the formula of the above-mentioned water-based colorful luminescent pai...

Embodiment 2

[0057] The raw material formulation (wt%) of the water-based colorful luminous paint is shown in Table 2 below.

[0058] base paint

[0059] Deionized water 53.3% Silicone defoamer 0.15% Dispersant 0.4% 30,000 cellulose 0.8% Neutralizer 0.15% Pigments 12% lotion 22% thickener 0.2% luminescent agent 1.0% protective glue solution 10%

[0060] Finished color grain

[0061] protective glue solution 50% base paint 50%

[0062] Finished paint

[0063] Deionized water 36.45% Silicone acrylic emulsion 28% Coalescent 2.2% Finished Particles 28% thickener 0.35%

[0064] The raw material formula (wt %) of the waterborne multicolored luminescent paint of table 2 embodiment 2

[0065] The preparation method of water-based colorful luminous paint, it may further comprise the steps:

[0066] According to the formula of the above-mentioned water-based colorful lu...

Embodiment 3

[0070] The raw material formulation (wt%) of the water-based colorful luminescent coating is shown in Table 3 below.

[0071] The raw material formula (wt %) of the water-based multicolored luminescent paint of table 3 embodiment 3

[0072] base paint

[0073] Deionized water 52.02% Silicone defoamer 0.18% Dispersant 0.35% 30,000 cellulose 1.0% Neutralizer 0.15% Pigments 13% lotion 21% thickener 0.2% luminescent agent 1.1% protective glue solution 11%

[0074] Finished color grain

[0075] protective glue solution 40% base paint 60%

[0076] Finished paint

[0077] Deionized water 35.5% Silicone acrylic emulsion 32% Coalescent 2.1% Finished Particles 30%

[0078] thickener 0.4%

[0079] The preparation method of water-based colorful luminous paint, it may further comprise the steps:

[0080] According to the formula of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com