Processing method of coffeeberry peel and coffeeberry peel fermented wine prepared by method

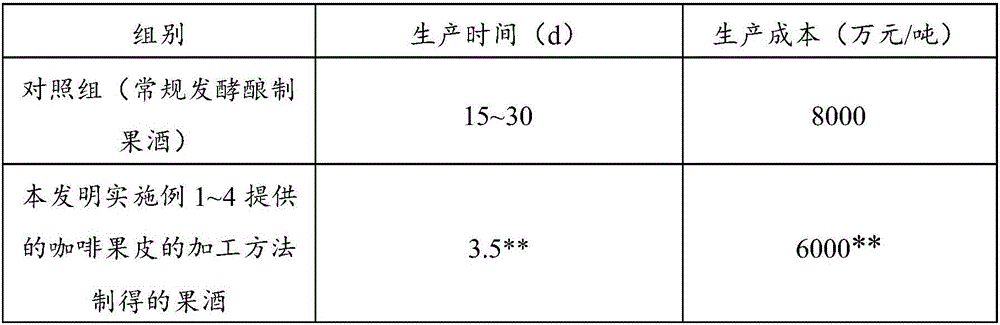

A processing method and fruit peel technology, applied in the field of brewing, can solve the problems of low utilization rate of coffee by-products, environmental pollution, waste of resources, etc., and achieve the effects of shortening production time, reducing production cost, and improving nutrients and taste and flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Peel superfine grinding

[0049] The dried coffee peel is ultrafinely pulverized, and the pulverized particle size is 110 mesh.

[0050] 2. Low-frequency microwave / enzymatic synergistic saccharification and degradation

[0051] 10w low-frequency microwave-assisted enzymatic method is used to degrade the coffee peel into small molecular sugars that can be directly used for fermentation. The enzymes used are cellulase, pectinase and pancreatin, the enzyme activity of cellulase is 20000u / g, and the addition amount is 0.05g / g; The enzyme activity is 4000u / g, and the addition amount is 0.01g / g; it acts for 1.5h at a temperature of 30°C and a pH value of 5.5.

[0052] 3. Add auxiliary materials to sterilize the inoculum

[0053] Using the saccharification liquid as raw material, add white sugar to adjust the sugar content to 22Brix, add sodium bisulfite to make the SO in the fermentation liquid 2 The concentration is 27mg / kg, and the pH is adjusted to 6.5. After adjus...

Embodiment 2

[0059] 1. Peel superfine grinding

[0060] The dried coffee peel is ultrafinely pulverized, and the pulverized particle size is 150 mesh.

[0061] 2. Low-frequency microwave / enzymatic synergistic saccharification and degradation

[0062] A 50w low-frequency microwave-assisted enzymatic method is used to degrade the coffee peel into small molecular sugars that can be directly used for fermentation. The enzymes used are cellulase, pectinase and pancreatin, the enzyme activity of cellulase is 20000u / g, and the addition amount is 0.08g / g; The enzyme activity is 4000u / g, and the addition amount is 0.05g / g; it acts for 3 hours at a temperature of 40°C and a pH value of 7.

[0063] 3. Add auxiliary materials to sterilize the inoculum

[0064] Using the saccharification liquid as the raw material, add white sugar to adjust the sugar content to 18Brix, add sodium bisulfite to make the SO in the fermentation liquid 2 The concentration is 20 mg / kg, and the pH is adjusted to 7.0. Aft...

Embodiment 3

[0070] 1. Peel superfine grinding

[0071] The dried coffee peel is ultrafinely pulverized, and the pulverized particle size is 135 mesh.

[0072] 2. Low-frequency microwave / enzymatic synergistic saccharification and degradation

[0073] 100w low-frequency microwave-assisted enzymatic method is used to degrade the coffee peel into small molecular sugars that can be directly used for fermentation. The enzymes used are cellulase, pectinase and pancreatin, the enzyme activity of cellulase is 20000u / g, and the addition amount is 0.1g / g; The enzyme activity is 4000u / g, and the addition amount is 0.1g / g; the temperature is 50°C and the pH value is 6 for 1 hour.

[0074] 3. Add auxiliary materials to sterilize the inoculum

[0075] Using the saccharification liquid as raw material, add white sugar to adjust the sugar content to 24Brix, add sodium bisulfite to make the SO in the fermentation liquid 2 The concentration is 35 mg / kg, and the pH is adjusted to 5.5. After adjustment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com