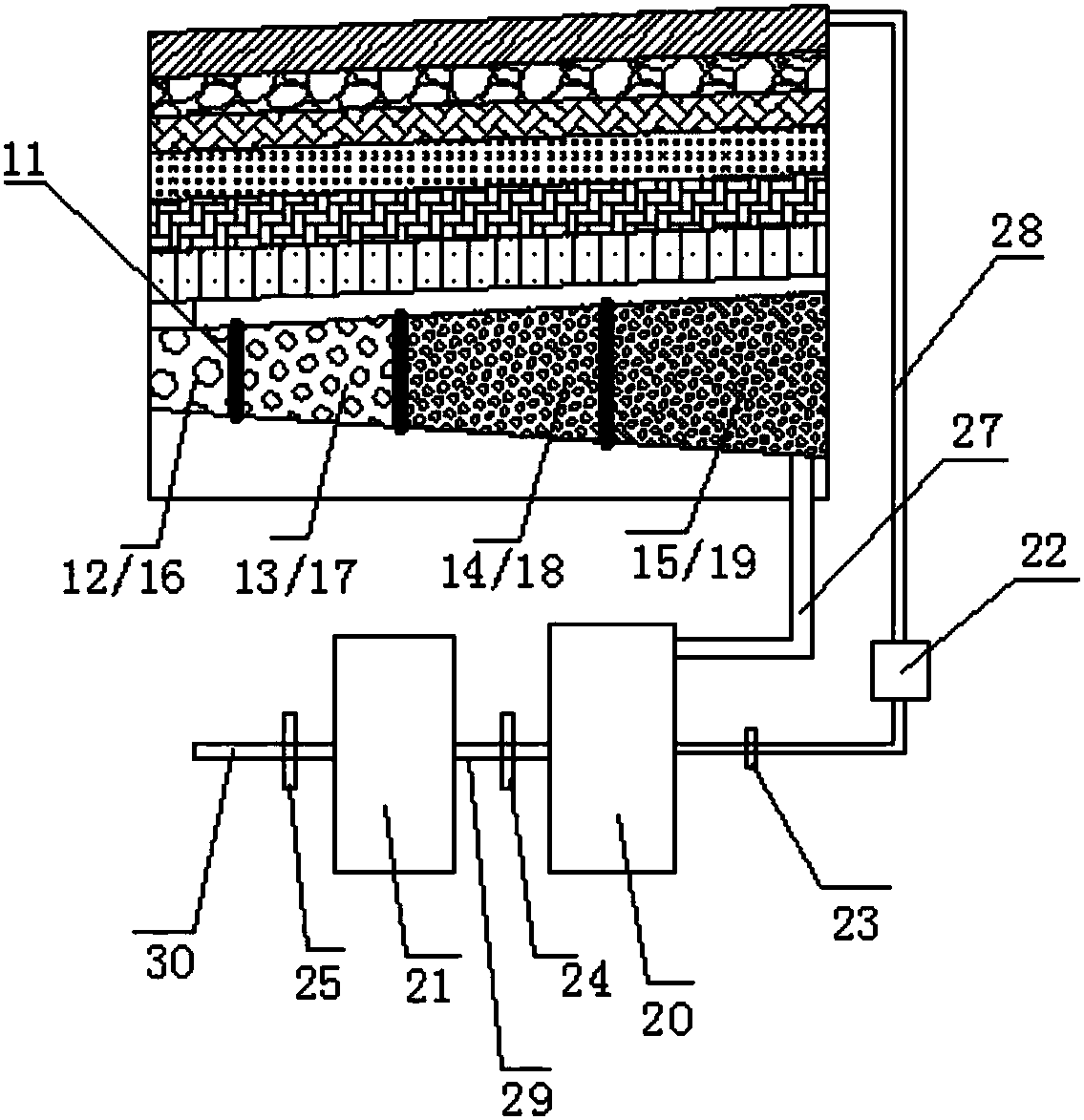

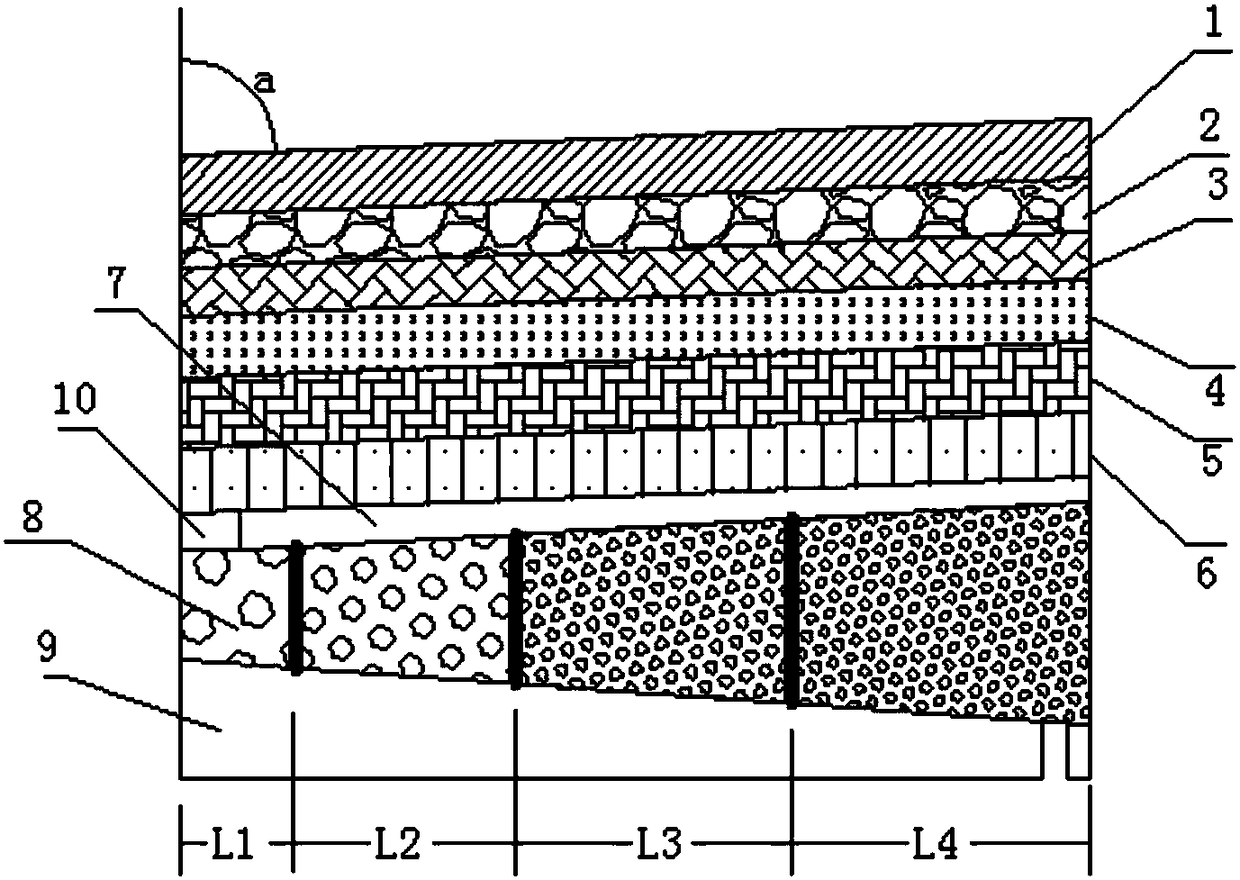

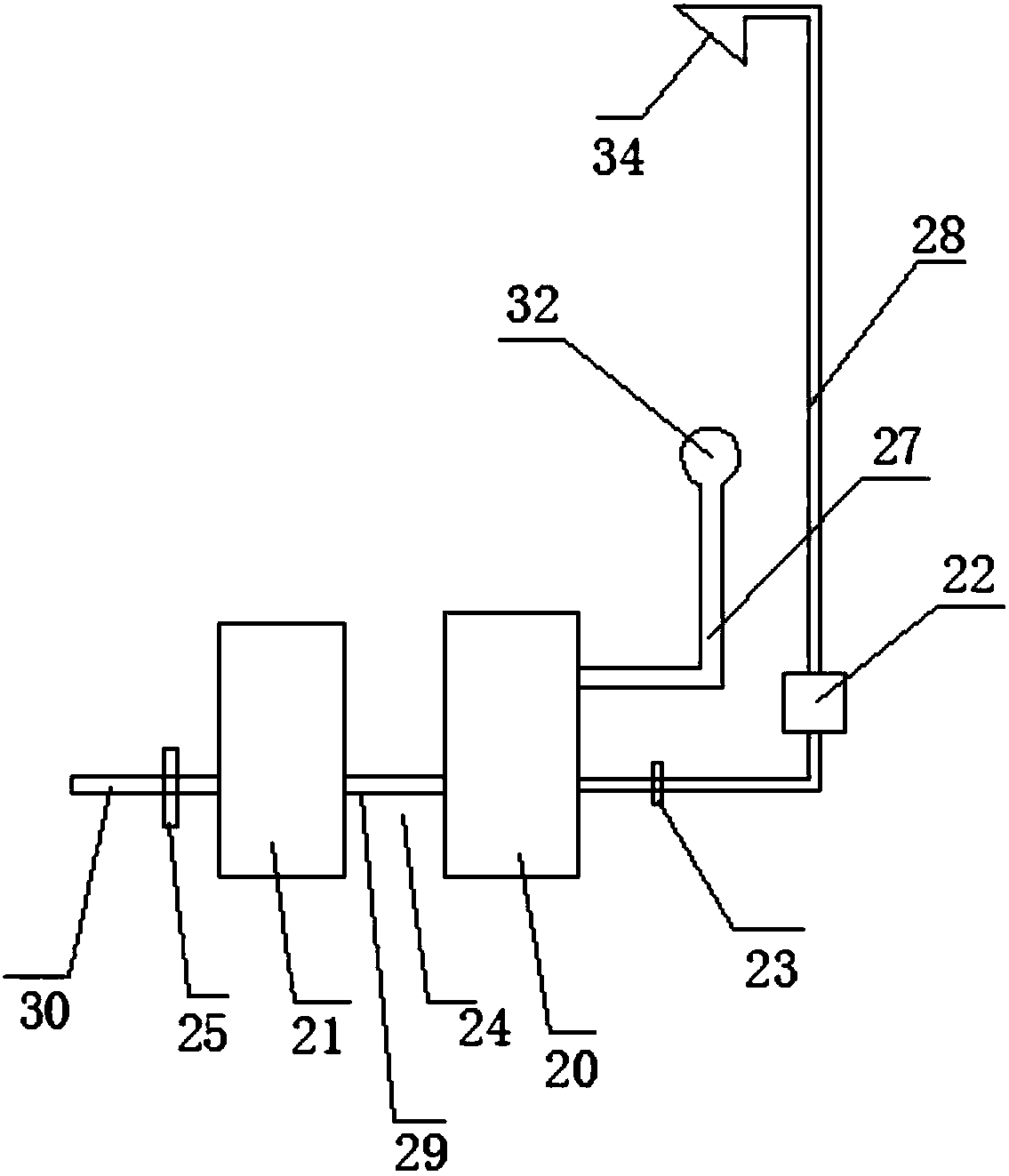

Rainwater collection roof rain garden

A rain garden and rain collection technology, which is applied to roofs, water supply devices, drinking water devices, etc., can solve problems such as rainwater discharge, achieve the effects of reducing work pressure, reducing urban drainage pressure, and ensuring safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of above-mentioned water inlet mechanism is:

[0051] (1) 45 parts of polyvinyl chloride resin, 15 parts of epoxy resin and 30 parts of polyurethane are heated and stirred at a temperature of 50-60° C. to obtain mixture A in parts by weight;

[0052] (2) 7 parts by weight of pentaerythritol, 14 parts of aluminum oxide, 3.5 parts of calcium isooctanoate, and 10.5 parts of deionized water were stirred at room temperature to obtain mixture B;

[0053] (3) After mixing 8 parts of mixture A, mixture B, talc powder with a particle diameter of 55 nanometers, 22.5 parts of methyl methacrylate, 11 parts of paraffin, 12 parts of cyclohexanone, and 4 parts of hydrogen peroxide in parts by weight Heating is carried out at a rate of 5°C / 4min until the temperature rises to 125°C, and then the mixture is kept at this temperature and heated for 40 minutes;

[0054] (4) Put the mixture into the injection molding machine and inject it into the molding machine.

Embodiment 2

[0056] The preparation method of above-mentioned water inlet mechanism is:

[0057] (1) In parts by weight, 30 parts of polyvinyl chloride resin, 10 parts of epoxy resin and 15 parts of polyurethane are heated at a temperature of 50° C. while stirring to uniformly obtain mixture A;

[0058] (2) Mix 5 parts of pentaerythritol, 10 parts of aluminum oxide, 2.5 parts of calcium isooctanoate, and 7.5 parts of deionized water in parts by weight at room temperature to obtain mixture B;

[0059] (3) Mix mixture A, mixture B, 5 parts of talcum powder with a particle diameter of 55 nanometers, 20 parts of methyl methacrylate, 8 parts of paraffin, and 10 parts of cyclohexanone in parts by weight and then heat them. Raise the temperature at a speed of / 4min until the temperature rises to 120°C, then continue to maintain this temperature and heat the mixture for 30min;

[0060] (4) Put the mixture into the injection molding machine and inject it into the molding machine.

Embodiment 3

[0062] The preparation method of above-mentioned water inlet mechanism is:

[0063] (1) In parts by weight, 60 parts of polyvinyl chloride resin, 20 parts of epoxy resin and 30 parts of polyurethane are heated while stirring at a temperature of 60° C. to obtain mixture A;

[0064] (2) 8 parts by weight of pentaerythritol, 16 parts of aluminum oxide, 4 parts of calcium isooctanoate, and 12 parts of deionized water were uniformly stirred at room temperature to obtain mixture B;

[0065] (3) After mixing 10 parts of mixture A, mixture B, 10 parts of talc powder with a particle diameter of 60 nanometers, 25 parts of methyl methacrylate, 14 parts of paraffin, 15 parts of cyclohexanone, and 8 parts of hydrogen peroxide in parts by weight Heating is carried out at a rate of 5°C / 4min until the temperature rises to 130°C, and the mixture is then kept at this temperature for 40 minutes;

[0066] (4) Put the mixture into the injection molding machine and inject it into the molding machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com