Flame retardant type waterproof roll

A waterproof membrane and flame-retardant technology, which is applied in fire prevention, building insulation materials, building components, etc., can solve the problems of unsatisfactory waterproof performance, inability to achieve flame retardancy, and low service life, so as to achieve high strength and ensure safety The effect of durability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

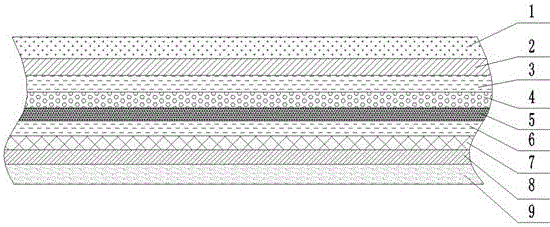

[0016] Such as figure 1 As shown, a flame-retardant waterproof roll material of the present invention includes a fine sand protective layer 1, a fireproof isolation layer 2, an upper TPO flame-retardant waterproof layer 3, a glass fiber mesh cloth layer 4, and an aluminum foil layer stacked one above the other in sequence 5. Lower TPO flame-retardant and waterproof layer 6, barrier layer 7, self-adhesive layer 8, and isolation layer 9.

[0017] Further, the fine sand protective layer 1 is a sand surface layer made of non-woven fabric and ore particles bonded on the non-woven fabric.

[0018] Further, the fire insulation layer 2 is an insulation layer made of waterproof material.

[0019] Further, the upper TPO flame-retardant waterproof layer 3 and the lower TPO flame-retardant waterproof layer 6 are thermoplastic elastomer TPO resin layers.

[0020] Further, the barrier layer 7 has a three-layer structure composed of a polyethylene PE layer, a polyvinyl alcohol PVA layer, and a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com