Coal bed gas well sand blasting perforation jet hole forming and fracturing integrated production increasing process method

A technology of sand blasting perforation and process method, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., which can solve the problem of small radiation area of fractures, achieve irregular fracture direction, strong pertinence, avoid The effect of the stuck column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

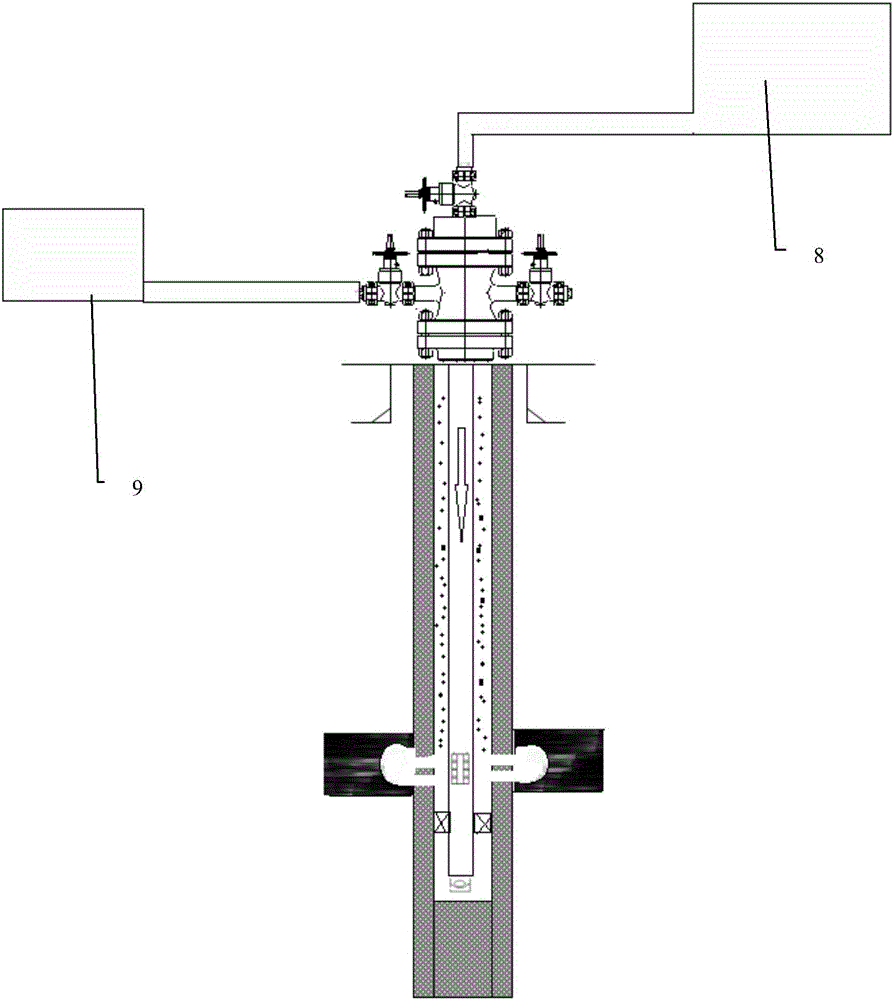

[0025] This embodiment is a single-layer construction, and the oil pipe 1 of the pipe string is a ball seat, a centralizer, and a spray gun from bottom to top.

[0026] 1. Run the fracturing string into the well to be stimulated.

[0027] In this embodiment, in order to fully create holes in the coal seam, the selection of the spray gun has also become the key. By selecting the size of the nozzle, the number of nozzles and the distribution, the working distance of the spray gun is increased, and the high-speed water flow can pass through the mud pollution zone. Act on the coal seam, so as to create holes in a larger space. The nozzles are spirally distributed on the spray gun, which can perforate the coal seam in all directions, so as to fully create holes. In this embodiment, a spray gun with a length of 1.2 meters and 6 nozzles with a diameter of 5.5 mm are selected. The material of the nozzles is tungsten alloy, which is a high-strength hard alloy, which meets the conditio...

Embodiment 2

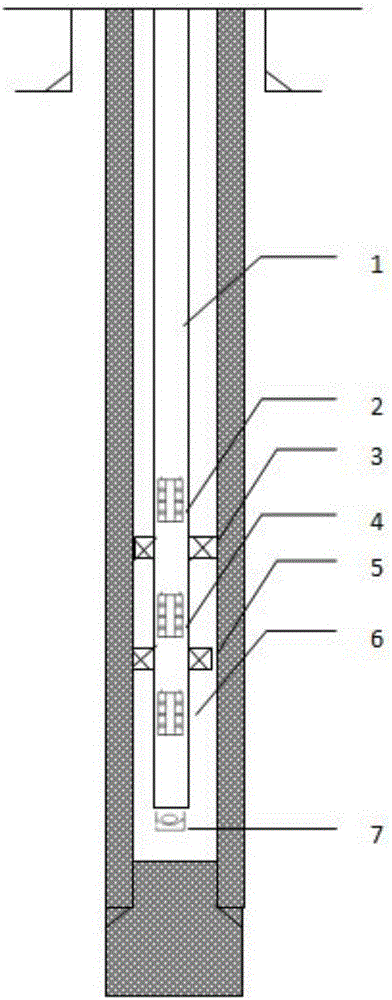

[0035] This embodiment is a multi-layer construction, the oil pipe 1 of the string is from bottom to top as the ball seat 7, the first layer of spray gun 6, the packer 5, the second layer of spray gun 4, the packer 3, and the third layer of spray gun 2 ;Such as figure 1 shown.

[0036] 1. Run the pipe string in the required reconstruction well.

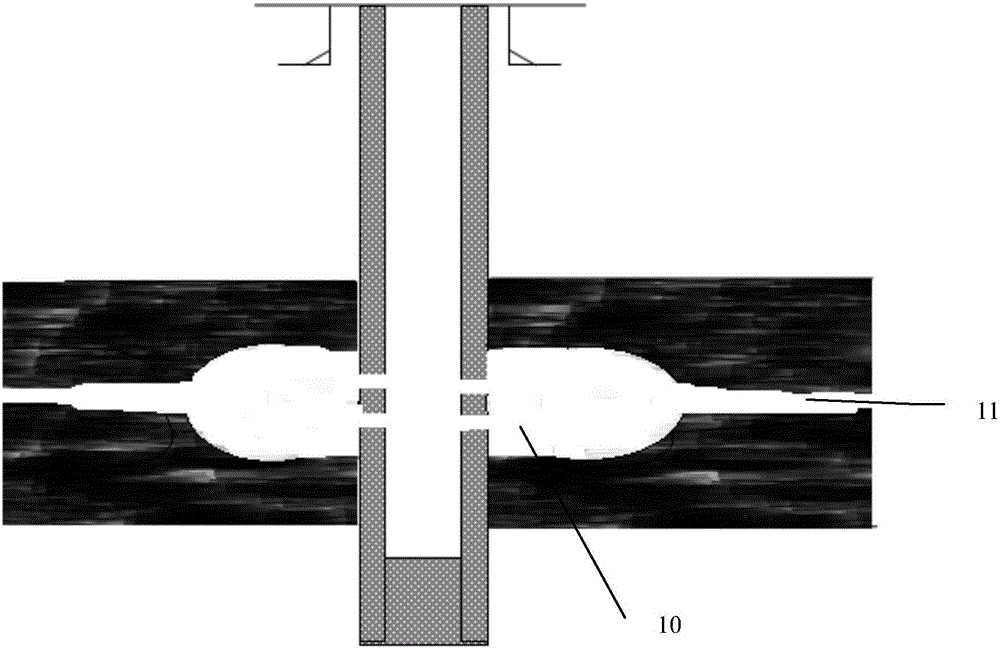

[0037]2. Perform sand blasting and perforation on the reformed well to open the coal seam, put in steel balls corresponding to the first layer of spray guns, knock down the first layer of spray gun sliding sleeves, establish a sand blasting perforation channel, and spray the casing through hydraulic sand blasting. Holes (the specific operation is to inject high-pressure fluid containing about 10% gravel into the pipe string to shoot open the casing), open the coal seam, and establish channels.

[0038] 3. Carry out cave-making reconstruction for the reformed well, and create caves in the coal seam by holding pressure and blowing out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com