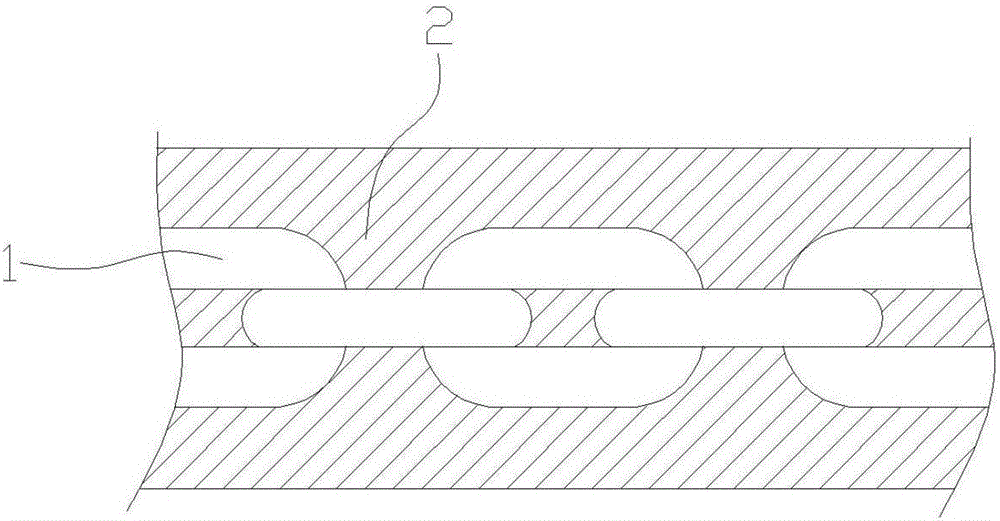

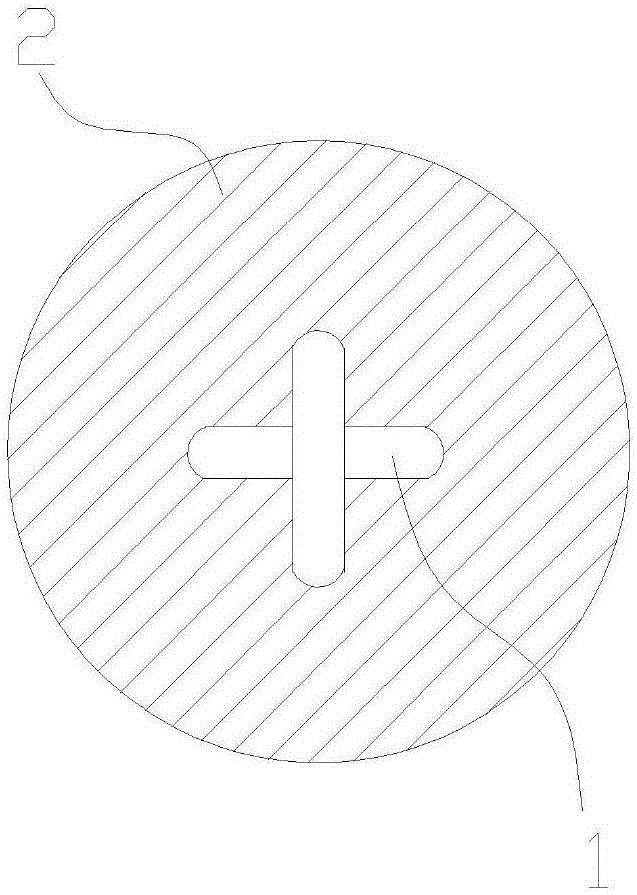

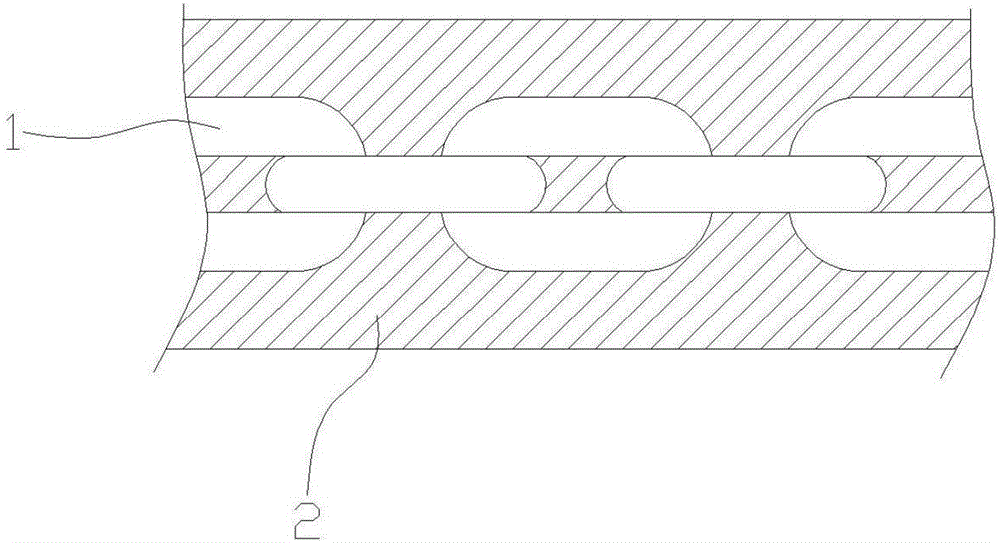

Wide-body elevator balance compensation chain and production process thereof

A technology of balance compensation and production process, applied in the direction of drag chain, hanging chain, transmission chain, etc., can solve the problems of loud noise, easy cracking, inflexible bending, etc., and achieve the effect of reducing noise, high toughness, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Raw materials in the outer coating layer 2: styrene-based block copolymers, polyolefin thermoplastic elastomers, flame-retardant silicon masterbatches, intumescent flame retardants, flame-retardant synergists and processing aids. The mass percentages are:

[0029]

[0030] The raw materials are taken according to the above-mentioned components and their percentages. Among them, the styrene-based block copolymer adopts styrene-ethylene-propylene-styrene block copolymerization with a styrene content of 10%; the silicon polymer in the flame-retardant silicon masterbatch The concentration is 15%, polysiloxane is used as silicon polymer; melamine borate phosphate is used as intumescent flame retardant; silica and montmorillonite are used as flame retardant synergist; processing aids include: antioxidant, Lubricants, fillers, and colorants. Among them, auxiliary antioxidants are used as antioxidants, erucamides and silicone masterbatches are used as lubricants, and montmori...

Embodiment 2

[0032] Raw materials in the outer coating layer 2: styrene-based block copolymers, polyolefin thermoplastic elastomers, flame-retardant silicon masterbatches, intumescent flame retardants, flame-retardant synergists and processing aids. The mass percentages are:

[0033]

[0034] The raw materials are taken according to the above-mentioned ingredients and their percentages. Among them, the styrene-based block copolymer adopts styrene-ethylene-propylene-styrene block copolymerization with a styrene content of 20%; the silicon polymer in the flame-retardant silicon masterbatch The concentration is 40%, polysiloxane is used as the silicon polymer; melamine borate phosphate is used as the intumescent flame retardant; titanium dioxide is used as the flame retardant synergist; processing aids include antioxidants, lubricants, and fillers, among which, The antioxidant is aromatic amine antioxidant, the lubricant is stearic acid and oleic acid amide, and the filler is clay, talcum p...

Embodiment 3

[0036] Raw materials in the outer coating layer 2: styrene-based block copolymers, polyolefin thermoplastic elastomers, flame-retardant silicon masterbatches, intumescent flame retardants, flame-retardant synergists and processing aids. The mass percentages are:

[0037]

[0038]The raw materials are taken according to the above-mentioned ingredients and their percentages. Among them, the styrene-based block copolymer adopts styrene-ethylene-propylene-styrene block copolymerization with a styrene content of 55%; the silicon polymer in the flame-retardant silicon masterbatch The concentration is 65%, polysiloxane is used as the silicon polymer; melamine borate phosphate is used as the intumescent flame retardant; magnesium oxide and montmorillonite are used as the flame retardant synergist; processing aids include antioxidants, lubricants , fillers and coloring agents, wherein the antioxidants are hindered phenolic antioxidants, the lubricants are oleic acid amides and erucam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com