Assistant water cooling refrigerating system with vertical countercurrent direct contact condensation heat exchanger

A refrigeration system and heat exchanger technology, which is applied to direct contact heat exchangers, heat exchanger types, refrigerators, etc. Increase the power consumption and other problems to achieve the effect of increasing the cooling capacity, reducing the exhaust temperature and reducing the power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

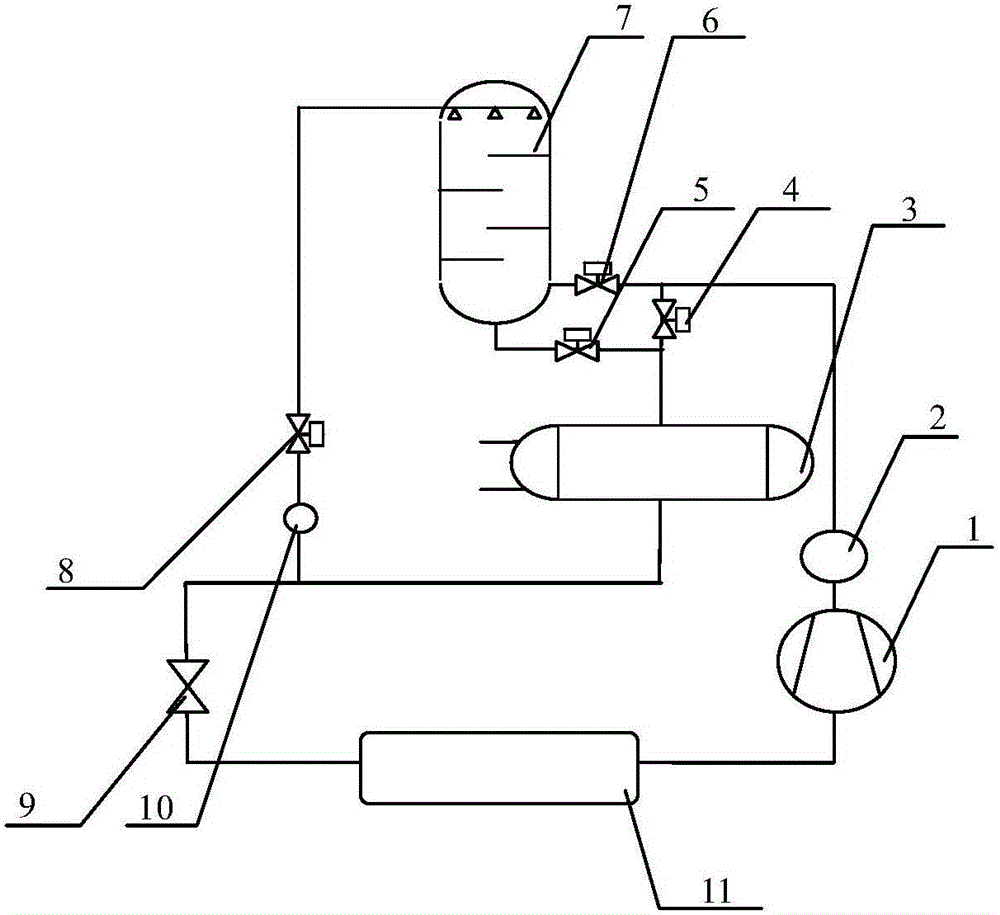

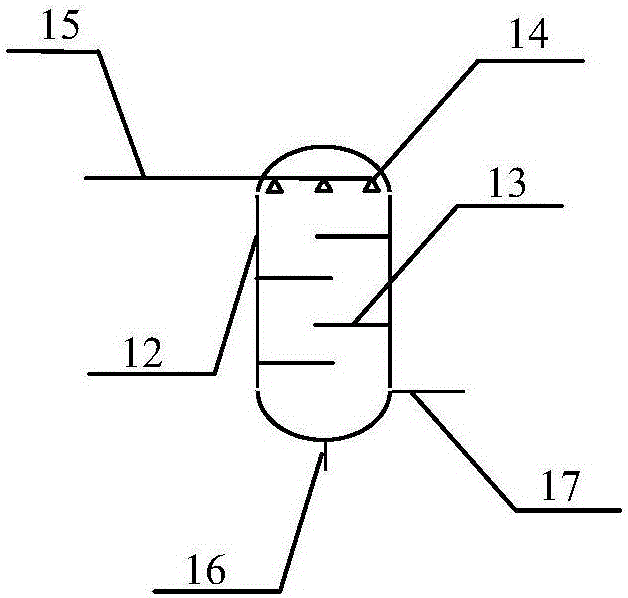

[0014] The schematic diagram of the auxiliary water-cooled refrigeration system with vertical counter-flow direct contact condensation heat exchanger of the present invention is as follows Figure 1-Figure 2 As shown, it includes refrigeration compressor 1, oil separator 2, auxiliary water-cooled heat exchanger 3, first solenoid valve 4, second solenoid valve 5, third solenoid valve 6, vertical countercurrent direct contact condensation heat exchanger 7, Fourth solenoid valve 8 , throttle valve 9 , liquid pump 10 , evaporator 11 , housing 12 , liquid baffle plate 13 and spray head 14 .

[0015] The vertical countercurrent direct contact condensation heat exchanger 7 is composed of a housing 12, a liquid baffle 13 and a nozzle 14. The inlet of the nozzle 14 is connected to the liquid supply pipe 15 and evenly distributed on the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com