Bunched cable suitable for outdoor video monitoring application

A technology of bundled cables and external video, which is applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of low adaptability to automobile rolling and can not withstand pressure, so as to facilitate wiring, improve rolling resistance, and improve The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

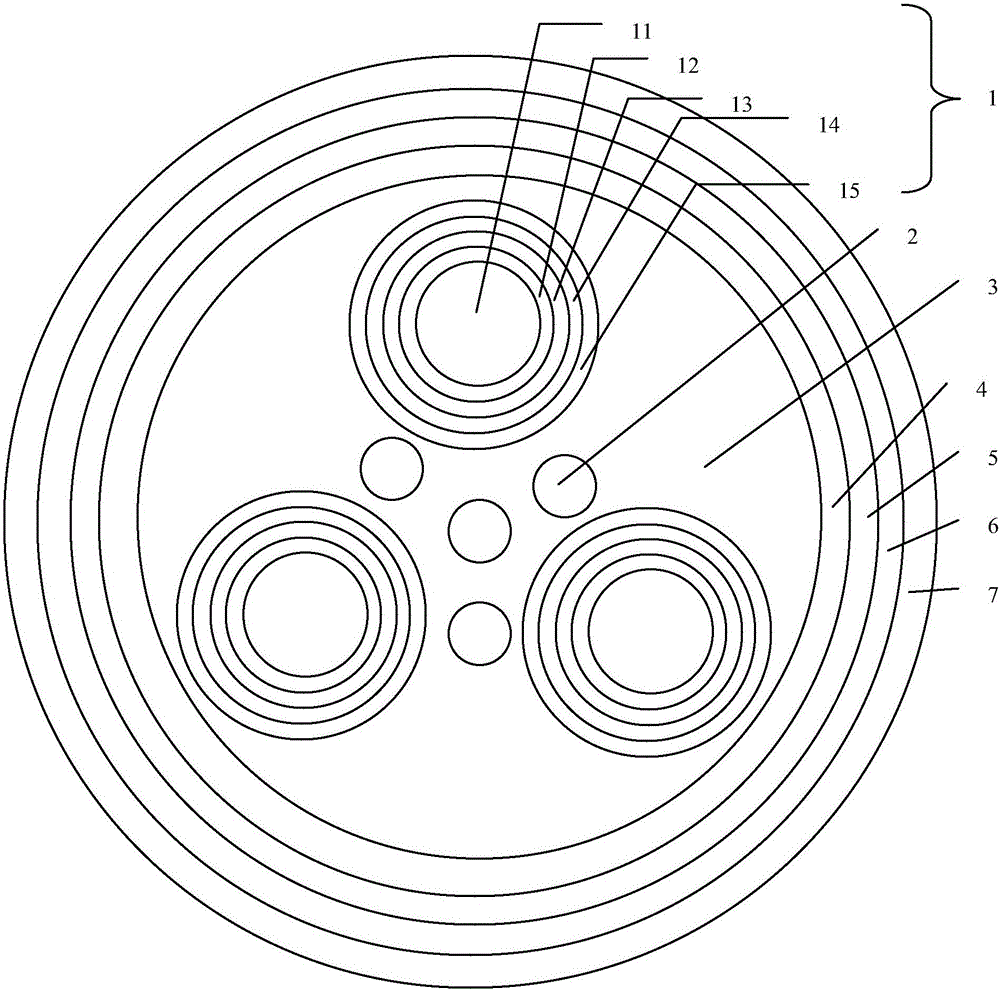

[0023] see figure 1 , a bundled cable suitable for outdoor video surveillance applications, including three finished cable cores 1, four Y-shaped steel wire ropes 2, the first insulating layer 4, braided shielding layer 5, alloy sheath 6, sheath layer 7, the distance between two of the three cable cores 1 is equal, three of the four steel wire ropes 2 are respectively distributed between two of the three cable cores 1, and the other of the four steel wire ropes 2 Distributed in the middle of the three cable cores 1, each cable core 1 includes a copper core conductor 11, a second insulating layer 12, an aluminum foil Mylar layer 13, a tinned copper wire braid 14 and a cladding layer 15, the copper core The conductor 11 is covered successively by the second insulation layer 12, the aluminum foil Mylar layer 13, the tinned copper wire braid layer 14, and the cladding layer 15, and the three cable cores 1 and the four steel wire ropes 2 are covered by the first insulation layer 4 ...

Embodiment 2

[0030] Except modified polyethylene, coating layer, sheath layer, all the other are the same as embodiment 1.

[0031] The modified polyethylene is composed of the following raw materials in parts by weight: low-density polyethylene resin 80, gadolinium nitrate 12, silver sulfide 10, aluminum oxide 7, titanium sulfate 6, mica powder 8, methyltriacetoxysilane 6, plasticizer Agent 5.

[0032] The cladding layer is composed of the following raw materials in parts by weight: polyvinyl chloride resin 90, cerium sulfate 16, lanthanum hydroxide 18, plasticizer 6, chlorinated paraffin 15, calcium carbonate 25, tricumyl phosphate 12, stannic acid Zinc 5.

[0033] The sheath layer is composed of the following raw materials in parts by weight: polyvinyl chloride resin 100, zirconium n-propoxide 20, potassium fluorosilicate 15, sodium thiosulfate 20, mica 6, zinc oxide 5, plasticizer 5, polyphosphoric acid Ammonium 8, zeolite powder 6.

[0034] The universal material testing machine of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com