MEMS packaging structure with heat sink and electromagnetic shielding and preparation method thereof

A magnetic shielding and heating technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as weak signal interference, external electromagnetic signal interference, MEMS sensors can not work normally, etc., to achieve material realization, Effects of shortening the hot start time and shortening the thermal equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

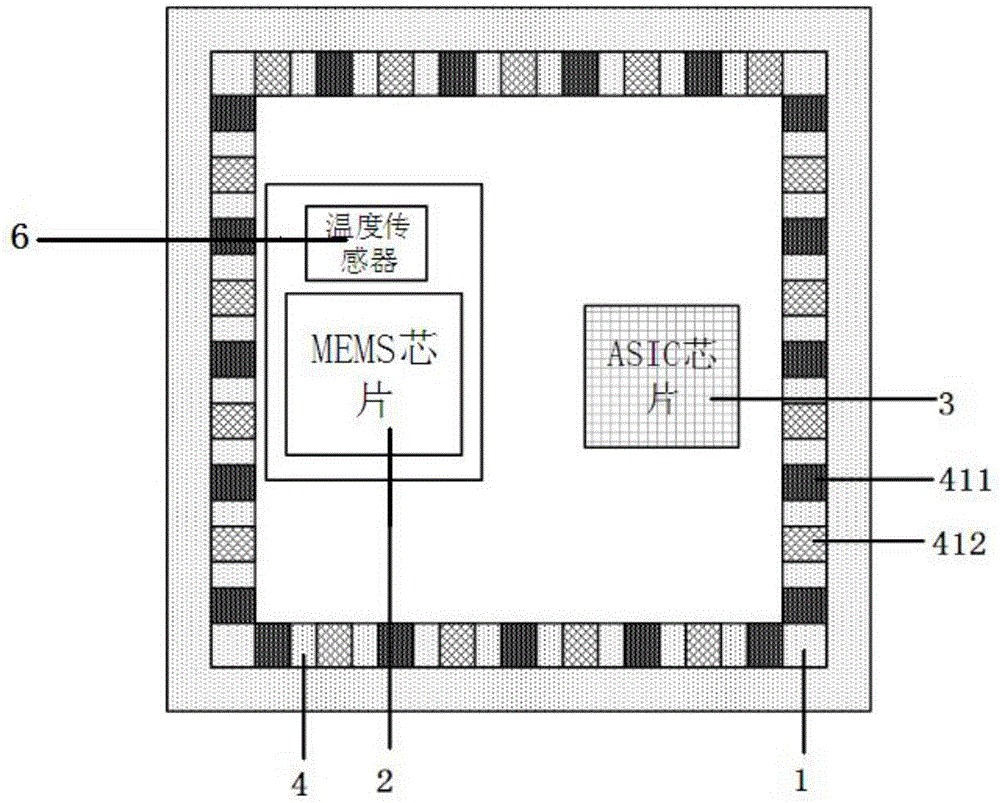

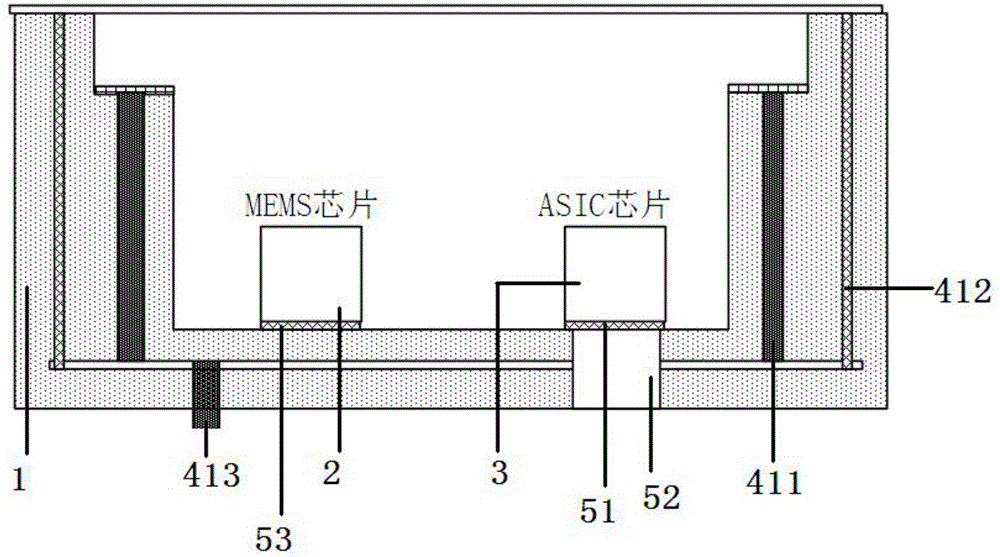

[0054] Such as figure 1 and image 3 As shown, a MEMS package with a heat sink and magnetic shielding, the MEMS package includes a package shell 1, a MEMS chip 2, an ASIC chip 3 and a temperature sensor 6, the package shell 1 is a cuboid structure, including four The side wall, the packaging tube shell is provided with a magnetic shielding passage, the magnetic shielding passage includes a metal vertical passage 41, a metal cover plate 42 and a metal bottom plate 43, the metal bottom plate 43 is a metal plate or a metal mesh, and the metal vertical The passage 41 includes a plurality of metal strips, and the plurality of metal strips are built in parallel on the side wall of the package package 1 in the vertical direction, and the plurality of metal strips include signal metal strips 411 and magnetic shielding metal strips 412. The signal metal strip 411 and the magnetic shielding metal strip 412 are arranged on the same layer, the signal metal strip 411 is used for signal tr...

Embodiment 2

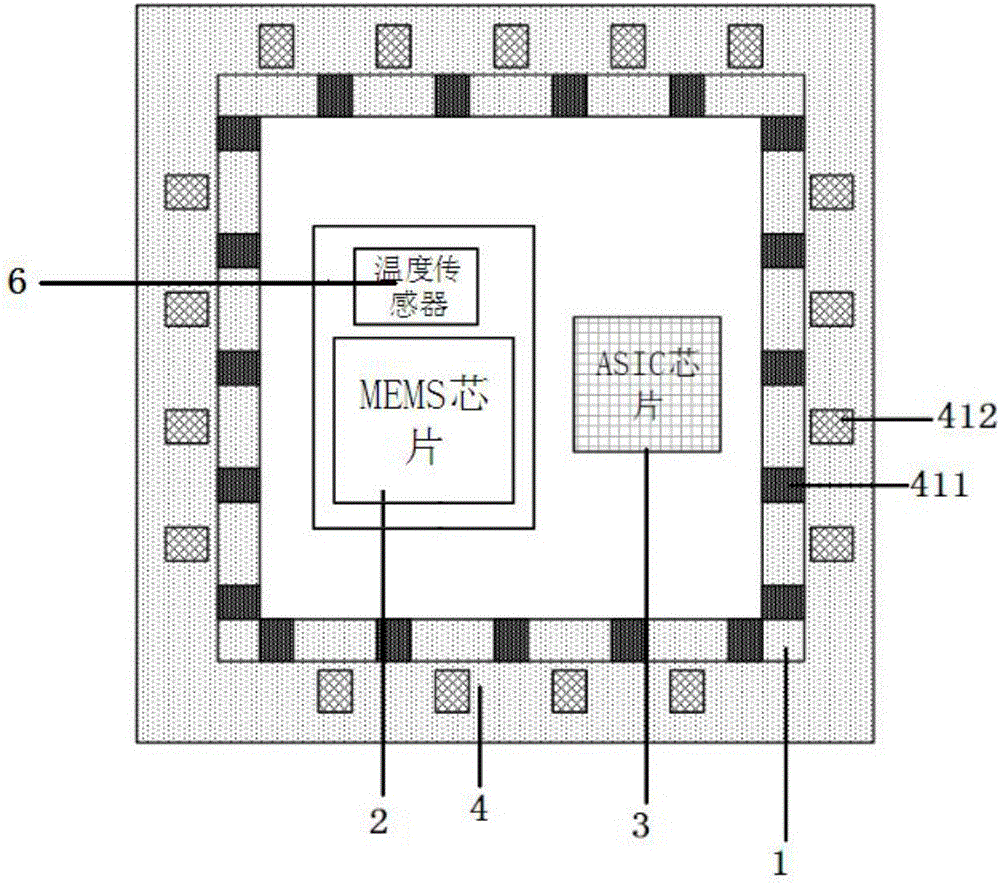

[0059] Such as Figure 2-Figure 3 As shown, a MEMS package with a heat sink and magnetic shielding, the MEMS package includes a package shell 1, a MEMS chip 2, an ASIC chip 3 and a temperature sensor 6, the package shell 1 is a cuboid structure, including four The side wall, the packaging tube shell is provided with a magnetic shielding passage, the magnetic shielding passage includes a metal vertical passage 41, a metal cover plate 42 and a metal bottom plate 43, the metal bottom plate 43 is a metal plate or a metal mesh, and the metal vertical The passage 41 includes a plurality of metal strips, and the plurality of metal strips are built in parallel on the side wall of the package package 1 in the vertical direction, and the plurality of metal strips include signal metal strips 411 and magnetic shielding metal strips 412. The signal metal strip 411 and the magnetic shielding metal strip 412 are arranged on different layers, the signal metal strip 411 is located near the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com