Low-cost packaging bonding silver alloy wire and preparation method thereof

A silver alloy, low-cost technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of coating stability and environmental protection requirements restricting materials, high manufacturing costs, and improve LED luminous attenuation efficiency and easy operation. , The effect of superior welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention relates to a bonding silver alloy wire for low-cost and high-stability packaging and a preparation method thereof, wherein the composition of the bonding silver alloy wire is: Au<1%, Pd 1000-10000ppm, Pb10-200ppm, Mg 5ppm, and the rest are Ag.

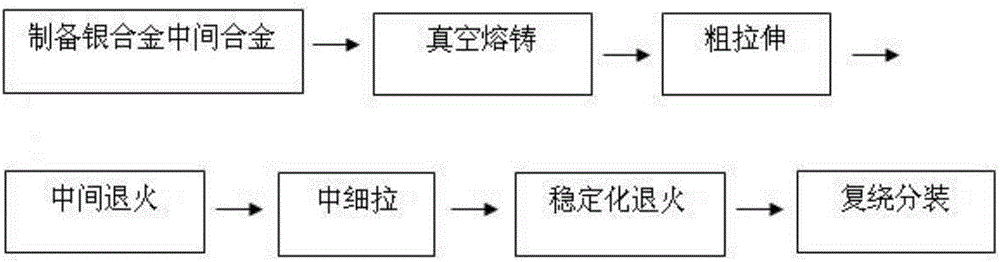

[0046] The preparation method comprises the following steps: 1. material preparation; 2. preparation of master alloy; 3. vacuum melting and drawing casting; 4. rough drawing; 5. intermediate annealing;

[0047] 1. Prepare materials. Weigh a number of 99.99% silver ingots, 500g of gold with a purity of not less than 99.99%, 2kg of industrial pure palladium flakes, 500g of pure magnesium pellets, and 500g of lead pellets.

[0048] 2. Preparation of master alloy.

[0049] aPut 1.5kg of palladium flakes into the crucible, heat the temperature to 1600 degrees under vacuum, after the palladium flakes are completely melted, put 1kg of silver ingots into the molten palladium liquid, stop heating when all the silv...

Embodiment 2

[0060] Vacuum melting and drawing casting. Put 4930g of silver ingot into a vacuum furnace and heat it to about 1000 degrees to melt, then add 50g of silver-palladium master alloy described in Example 1, 0.5g of silver-magnesium master alloy, 20g of gold grains, and 0.05g of lead grains in sequence under a protective atmosphere. Stir under vacuum, continue to stir for 10 minutes after all melting, and then carry out drawing casting into 8mm diameter alloy rod.

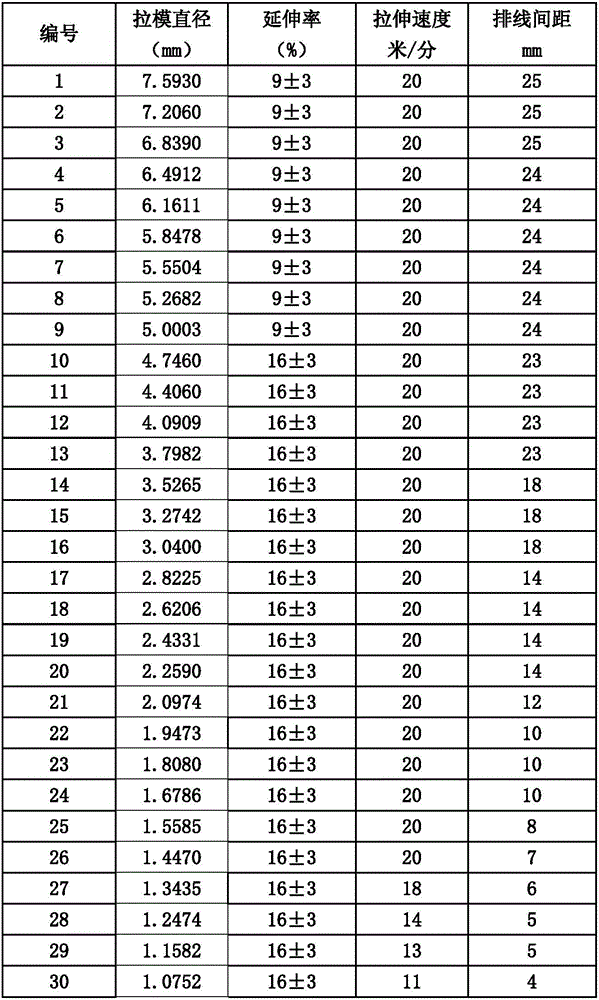

[0061] 2), rough drawing. The alloy rod was drawn to 3.0 mm by multiple drawing.

[0062] 3), intermediate annealing. The 3.0mm wire is annealed in a protective atmosphere, the annealing temperature is controlled at 400-450 degrees, and the line speed is controlled at about 500mm / min.

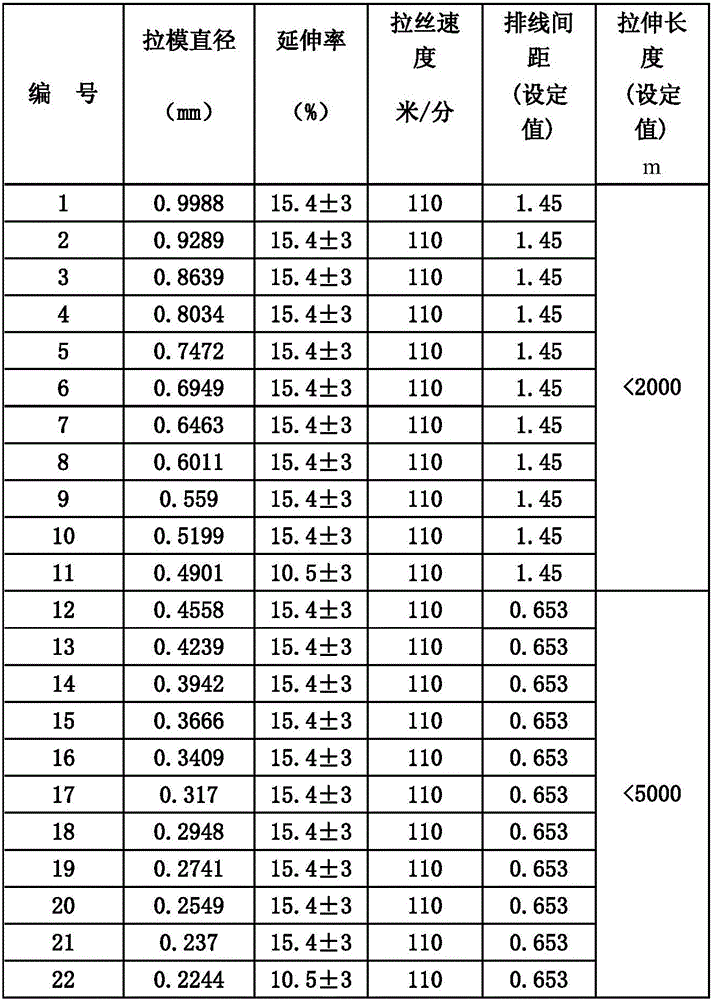

[0063] 4), medium selah. The annealed wire rod is drawn to 0.025mm through multiple passes.

[0064] 5), stabilization annealing. The 0.025mm microwire is stabilized by annealing, the annealing temperature is controlled at 400-450...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com