Cefalexin oil suspension and preparation method thereof

A technology of cephalexin oil and cephalexin, which is applied in the field of medicine, can solve the problems of inability to disperse agglomeration, prone to flocculation, waste of medicines, etc., and achieves the advantages of good needle penetration and dispersibility, high sample qualification rate and good application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

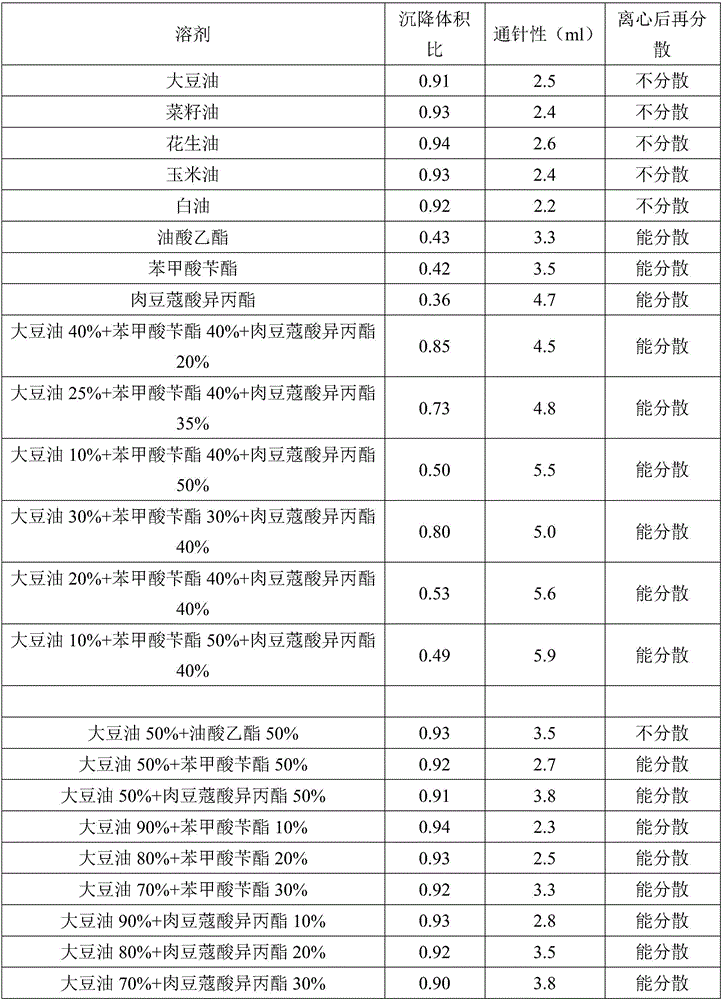

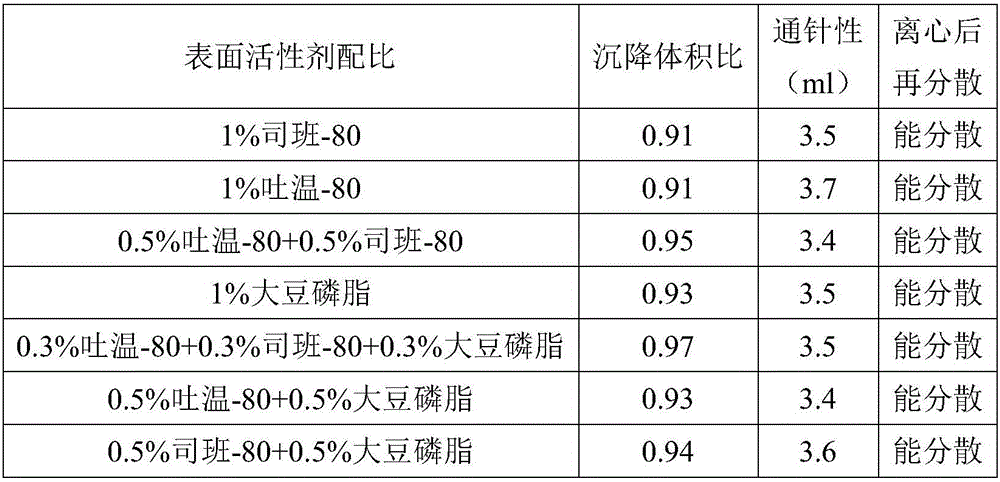

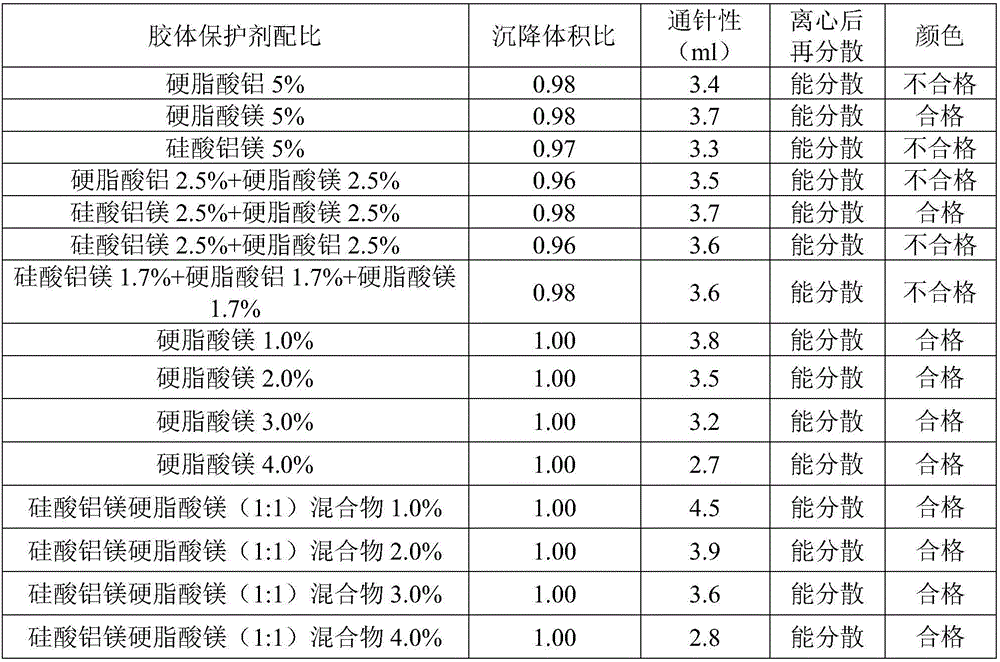

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 cephalexin oil suspension of the present invention

[0023] Take 30ml of soybean oil, add 30ml of benzyl benzoate, heat (60°C-70°C) and mix well, then add 1.0g of the colloidal protective agent magnesium aluminum silicate magnesium stearate (1:1) mixture, dissolve, and then add auxiliary Suspension agent (poloxamer 188 5.0g, polyethylene glycol 6000 2.5g) melted and stirred evenly, added surfactant soybean lecithin 0.3g, Tween-80 0.3g and Span-800.3g, after cooling, added auxiliary Suspension (1.0 g of sodium carboxymethyl cellulose), stirred evenly, added 10 g of cephalexin, after stirring evenly, settled the volume to 100 ml with soybean oil, and homogenized to obtain 10% cephalexin oil suspension.

Embodiment 2

[0024] The preparation of embodiment 2 cephalexin oil suspensions of the present invention

[0025] Take 30ml of soybean oil, add 30ml of isopropyl myristate, heat (60°C-70°C) and mix well, then add 1.0g of the colloidal protective agent magnesium aluminum silicate magnesium stearate (1:1), dissolve, and then Add suspending agent (poloxamer 188 1.0g, polyethylene glycol 6000 2.5g) to melt and stir evenly, add surfactant soybean lecithin 0.3g, Tween-80 0.3g and Span-80 0.3g, cool Add suspending agent (sodium carboxymethylcellulose 5.0g) afterward, stir evenly, add cephalexin 10g, after stirring evenly, settle to 100ml with soybean oil, homogeneously obtain 10% cephalexin oil suspension.

Embodiment 3

[0026] The preparation of embodiment 3 cephalexin oil suspensions of the present invention

[0027] Take 30ml of soybean oil, add 30ml of isopropyl myristate, heat (60°C-70°C) and mix well, then add 1.0g of the colloidal protective agent magnesium aluminum silicate magnesium stearate (1:1), dissolve, and then Add suspending agent (poloxamer 188 2.5g, polyethylene glycol 6000 5.0g) to melt and stir evenly, add surfactant soybean lecithin 0.3g, Tween-80 0.3g and Span-80 0.3g, cool Add suspending agent (sodium carboxymethylcellulose 5.0g) afterward, stir evenly, add cephalexin 10g, after stirring evenly, settle to 100ml with soybean oil, homogeneously obtain 10% cephalexin oil suspension.

[0028] The beneficial effect of the present invention is illustrated below in the mode of experimental example:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com