Method for low-cost industrialized preparation of recoverable degradable calcium phosphate bone fracture plate

A technology of calcium phosphate and bone plate, which is applied in medical science, surgery, etc., to achieve the effects of easy industrial production, low cost, recyclability and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

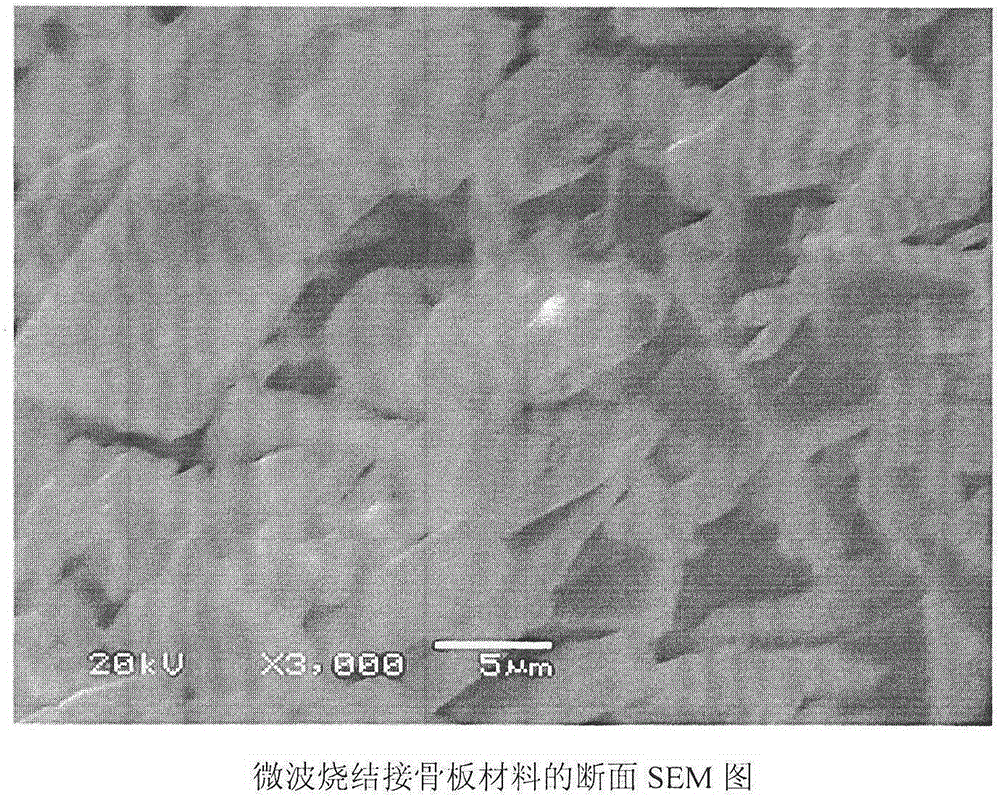

Image

Examples

Embodiment 1

[0030] Ammonium chloride and calcium carbonate are heated and reacted to generate CO2, ammonia gas, and calcium chloride. Add phosphoric acid to the above calcium chloride solution with a ratio of calcium to phosphorus of 3 / 2, and pass through the above CO2, ammonia gas, stir for 3 hours to form nano powder, filter and dry at 100 degrees, calcined at 900 degrees for later use, the filtrate chlorine Ammonium chloride recovery.

[0031] Repeat the above steps again, and add CTAB 1mol% weight ratio before passing the gas, and react the mixed solution for 10 hours to obtain whiskers after settling and filtering to obtain whiskers. The above calcium phosphate and whiskers are mixed at a ratio of 5 / 1, mixed evenly by ball milling for 1 hour, dry-pressed at 30 MPa to form a bone plate, and sintered in a microwave oven at 1100 degrees for 10 minutes to obtain nano-calcium phosphate ceramics. The bone plate was made after drilling to form threads. Finally, the used bone plate was clea...

Embodiment 2

[0033] Ammonium chloride and calcium carbonate are heated and reacted to generate CO2, ammonia gas, and calcium chloride. Add phosphoric acid to the above calcium chloride solution with a ratio of calcium to phosphorus of 3 / 2, and pass through the above CO2, ammonia gas, stir for 3 hours to form nano powder, filter and dry at 100 degrees, calcined at 900 degrees for later use, the filtrate chlorine Ammonium chloride recovery.

[0034] Repeat the above steps again, and add 1.5 mol% CTAB by weight before feeding the gas, and react the mixed solution for 10 hours to obtain whiskers after settling and filtering to obtain whiskers. The above calcium phosphate and whiskers are mixed at a ratio of 5 / 1, mixed evenly by ball milling for 1 hour, dry-pressed at 25MPa to form a bone plate, and sintered in a microwave oven at 1100 degrees for 10 minutes to obtain nano-calcium phosphate ceramics. The bone plate was made after drilling to form threads. Finally, the used bone plate was clean...

Embodiment 3

[0036] Ammonium chloride and calcium carbonate are heated and reacted to generate CO2, ammonia gas, and calcium chloride. Add phosphoric acid to the above calcium chloride solution with a ratio of calcium to phosphorus of 3 / 2, and pass through the above CO2, ammonia gas, stir for 3 hours to form nano powder, filter and dry at 100 degrees, calcined at 900 degrees for later use, the filtrate chlorine Ammonium chloride recovery.

[0037] Repeat the above steps again, and add CTAB 2mol% weight ratio before passing the gas, the mixed solution reacts for 10 hours, the whiskers are obtained after sedimentation, and the whiskers are obtained by filtration. The above calcium phosphate and whiskers are mixed at a ratio of 5 / 1, ball milled for 1 hour to mix evenly, dry-pressed at 28MPa to form a bone plate, and sintered in a microwave oven at 1100 degrees for 10 minutes to obtain nano-calcium phosphate ceramics. The bone plate was made after drilling to form threads. Finally, the used b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com