Method for preparing zinc phosphide/cobalt phosphide heterojunction photocatalyst based on MOFs template

A technology of photocatalyst and zinc phosphide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to improve photocatalytic performance, single composition, low light absorption utilization rate, etc. Achieve excellent photo-splitting water hydrogen production performance, easy to implement, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

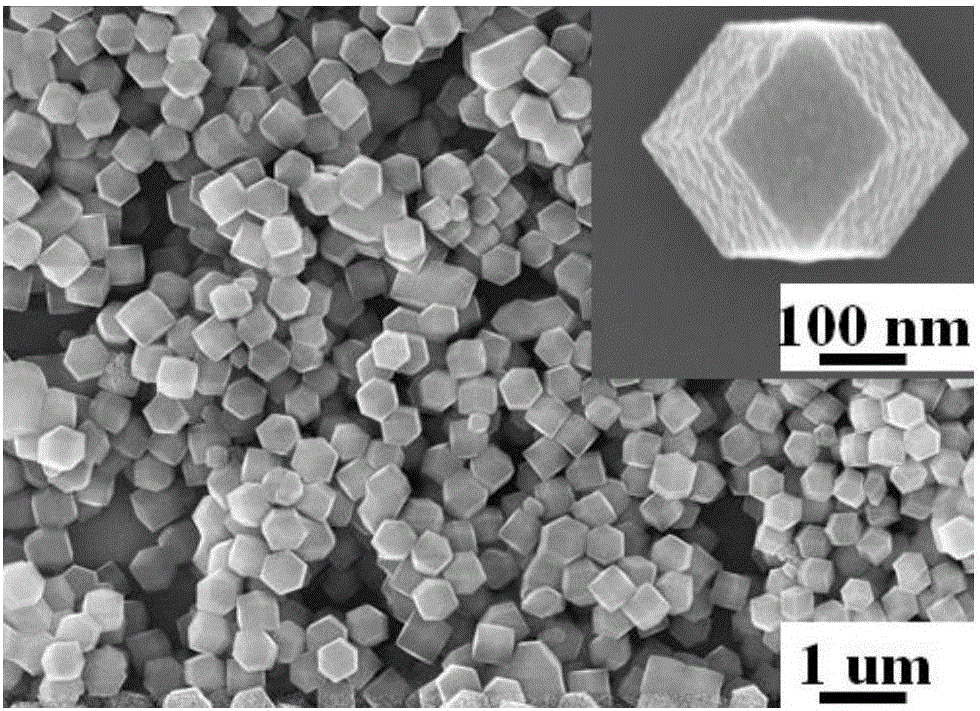

[0019] Step 1: Dissolve 0.656g of 2-methylimidazole, 0.249g of cobalt nitrate hexahydrate and 0.257g of zinc nitrate hexahydrate in 50mL of methanol under stirring at room temperature, let stand at room temperature for 24 hours, wash the mixture with methanol after centrifugation , activation, and vacuum drying at 60°C for 8 hours to obtain ZIF-ZnCo.

[0020] Step 2: Weigh 100 mg of ZIF-ZnCo prepared in Step 1, place it in a mortar and grind it for 5 minutes, and under air conditions, heat up to 300°C at a heating rate of 2°C / min and roast for 3h to obtain ZnO / Co 3 o 4 .

[0021] Step 3: Weigh 25 mg of ZnO / Co prepared in Step 2 3 o 4 , 0.6603gNaH 2 PO 2 ·H 2 O was placed in a mortar and ground for 10 min. Under the condition of nitrogen protection, the temperature was raised to 250 °C for 2 h at a rate of 2 °C / min. After the temperature dropped to room temperature, the obtained product was washed with deionized water and absolute ethanol, and heated at 60 °C. Dry under ...

Embodiment 2

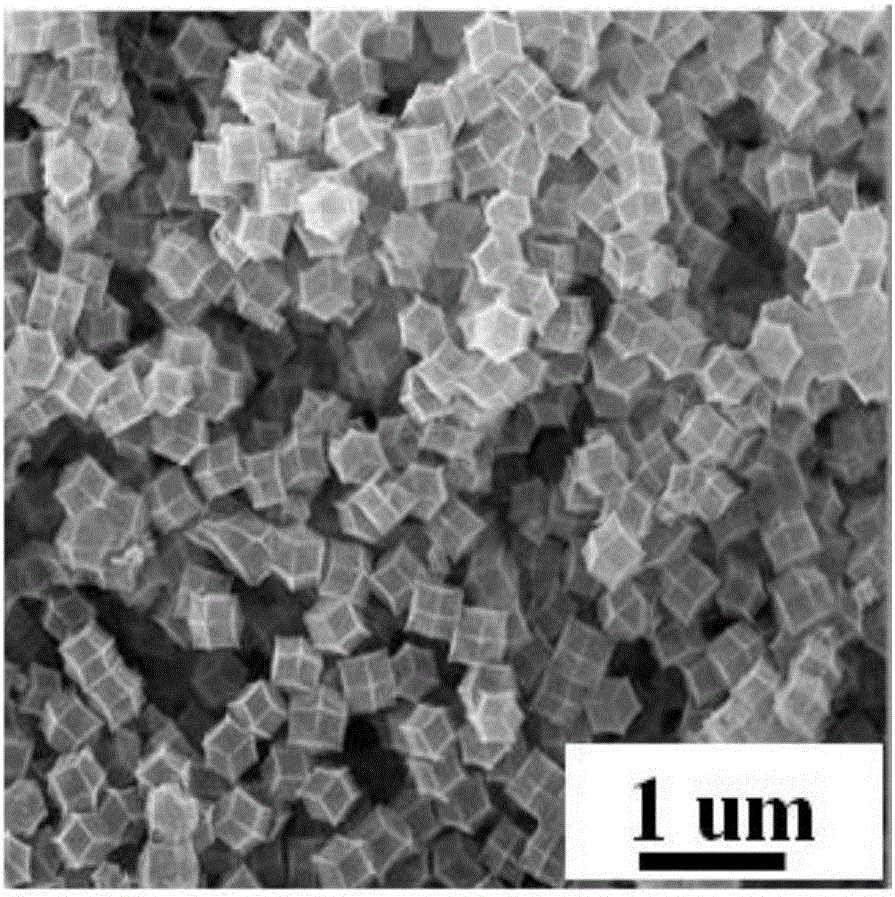

[0023] Step 1: Dissolve 0.656g of 2-methylimidazole, 0.249g of cobalt nitrate hexahydrate and 0.257g of zinc nitrate hexahydrate in 50mL of methanol under stirring at room temperature, let stand at room temperature for 24 hours, wash the mixture with methanol after centrifugation , activation, and vacuum drying at 60°C for 8 hours to obtain ZIF-ZnCo;

[0024] Step 2: Weigh 100 mg of the ZIF-ZnCo prepared in step 1, place it in a mortar and grind it for 5 minutes, and under air conditions, heat up to 400°C at a heating rate of 2°C / min and roast for 2h to obtain ZnO / Co 3 o 4 ;

[0025] Step 3: Weigh 25 mg of ZnO / Co prepared in Step 2 3 o 4 , 0.7000gNaH 2 PO 2 ·H 2 O was placed in a mortar and ground for 10 min. Under the condition of nitrogen protection, the temperature was raised to 300 ° C at a rate of 2 ° C / min for phosphating for 1 h. After the temperature dropped to room temperature, the obtained product was washed with deionized water and absolute ethanol. Dry und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com