Method for extracting green synthesis nanometer zero-valent iron through shaddock peels and application

A technology of pomelo peel extract and nano-zero-valent iron, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of using toxic chemical reagents, easy aggregation of particles, complicated processes, etc. Achieve the effect of high clearance rate, good dispersion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of pomelo peel extract comprises the steps:

[0032] 1) Weigh 10g of fresh pomelo peel, put it in 100ml of deionized water, and extract in a water bath at 60°C;

[0033] 2) Set the water bath extraction time to 20-120 minutes, and take samples every 20 minutes;

[0034] 3) The extracted extract was vacuum filtered, centrifuged at 14,000 rpm, passed through a 0.45 μm filter membrane, and the filtrate was refrigerated at 4° C. in a refrigerator.

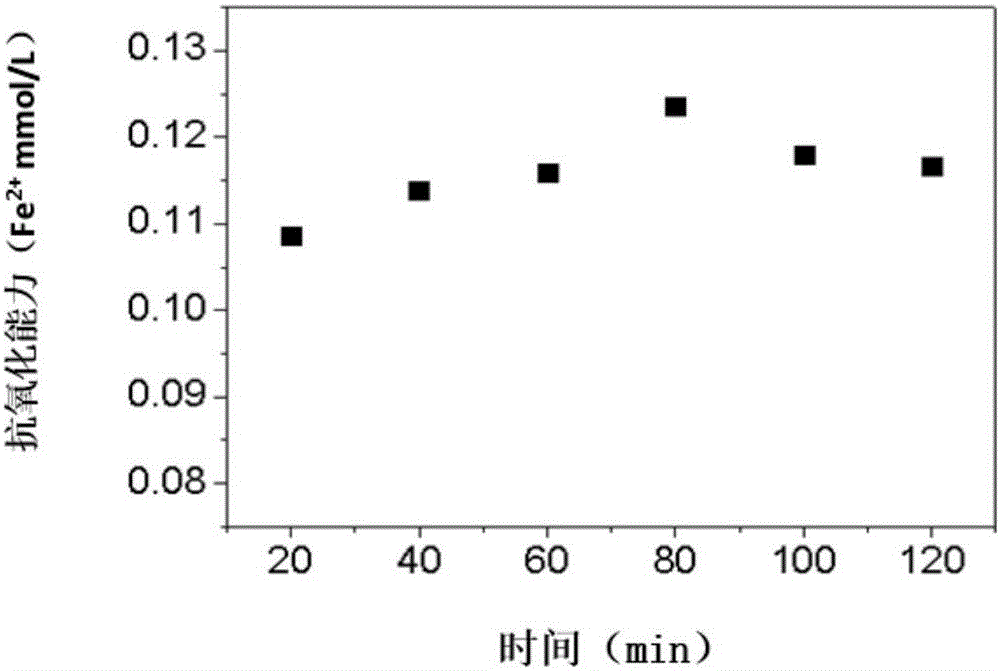

[0035] figure 1 The effect of time on the extraction effect in the extraction process of the prepared pomelo peel extract. Depend on figure 1 It can be seen that within 80 minutes, with the prolongation of the extraction time, the antioxidant capacity of the extract increases, and reaches the maximum at 80 minutes, so 80 minutes is the best extraction time.

Embodiment 2

[0037] The preparation method of pomelo peel extract comprises the steps:

[0038] 1) Weigh 10g of fresh pomelo peel, place it in 100ml deionized water, and extract in a water bath at 70°C;

[0039] 2) The water bath extractant is deionized water, wherein the deionized water is adjusted to pH with 0.1mol / L hydrochloric acid solution and sodium hydroxide solution, and extracted with different pH extractants;

[0040] 3) The extracted extract was vacuum filtered, centrifuged at 12000 rpm, passed through a 0.45 μm filter membrane, and the filtrate was refrigerated in a refrigerator at 4°C.

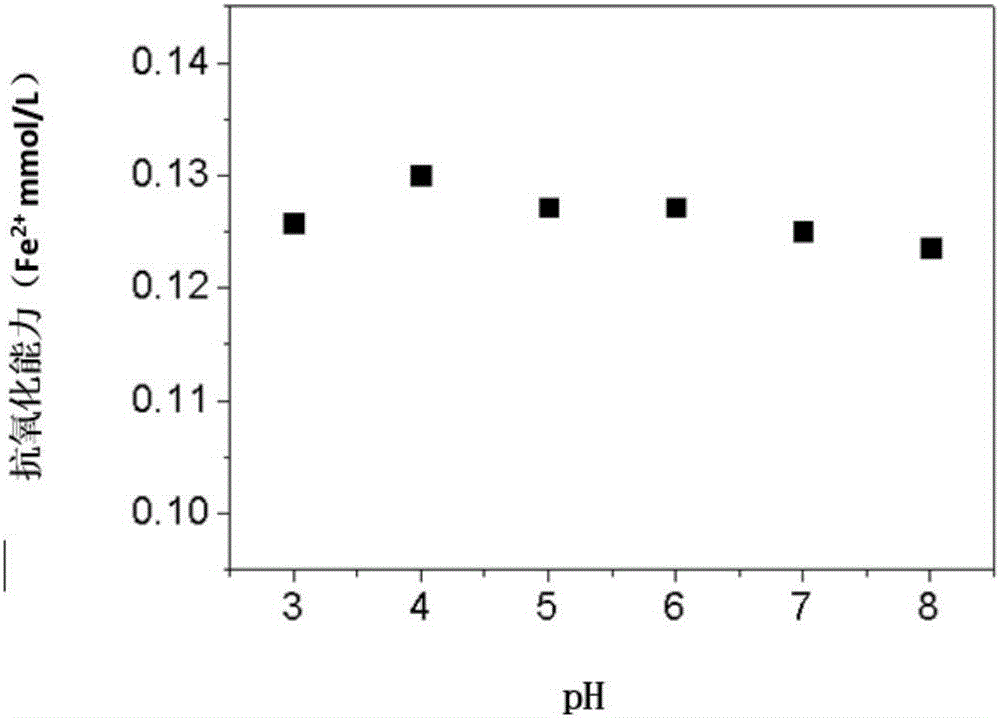

[0041] figure 2 The effect of different pH extractants on the extraction process of pomelo peel extract. The pH of pomelo peel extract is about 4.8, which is determined by figure 2 It can be seen that when the pH is between 4-5, the antioxidant capacity per unit mass is the largest, and when the pH exceeds 5, as the pH increases, the antioxidant capacity per unit mass of the extract grad...

Embodiment 3

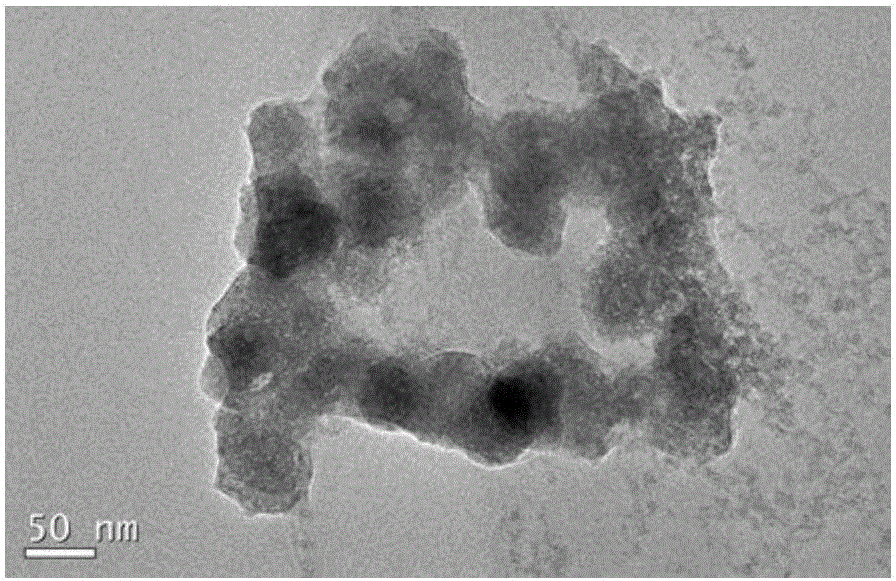

[0043] Green synthetic nano-iron particles Cm-Fe-NPs (citrus maxima in Latin name, Fe nanoparticles in English name of nano-iron, because this material is nano-iron particles synthesized by green grapefruit peel extract, so the material is named Cm-Fe- NPs) preparation method, comprises the steps:

[0044] 1) Weigh 10g of fresh pomelo peel, put it in 100ml of deionized water, and extract in a water bath at 90°C for 80min;

[0045]2) vacuum filter the extracted extract, centrifuge at 11,000 rpm, pass through a 0.45 μm filter membrane, and store the filtrate in a refrigerator at 4°C;

[0046] 3) Take 150ml pomelo peel extract and 50ml of 0.10moL / L FeSO 4 The solution was mixed and reacted under the protection of nitrogen at a volume ratio of 3:1. The color of the solution changed from yellow to black under stirring, and a solution containing green synthetic nano-iron particles was obtained. The generated material was centrifuged, and the centrifuged material was washed, After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com