Light aggregate concrete

A light aggregate concrete and mixture technology, applied in the field of building materials, can solve the problems of fresh concrete slump loss, large porosity of ceramsite concrete, high water absorption, etc., to broaden the scope of use, reduce salvage costs, improve flow sex change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

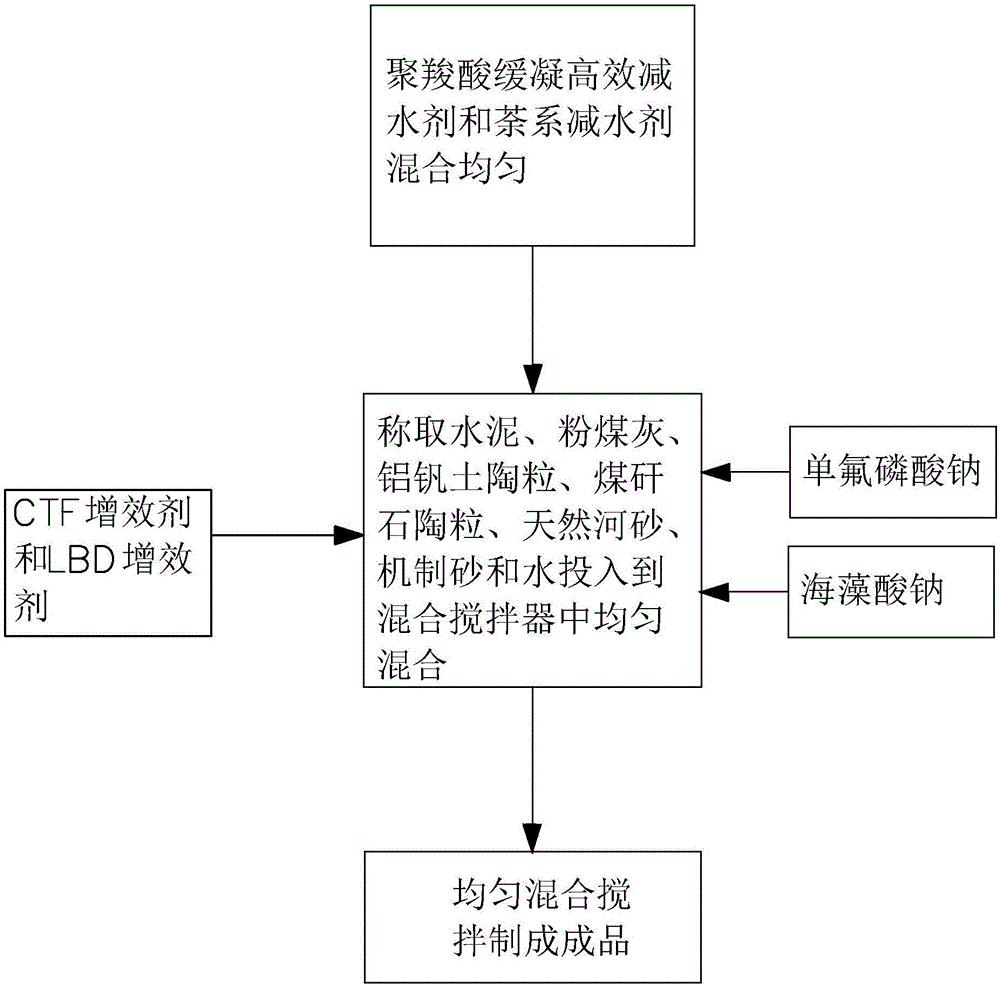

Method used

Image

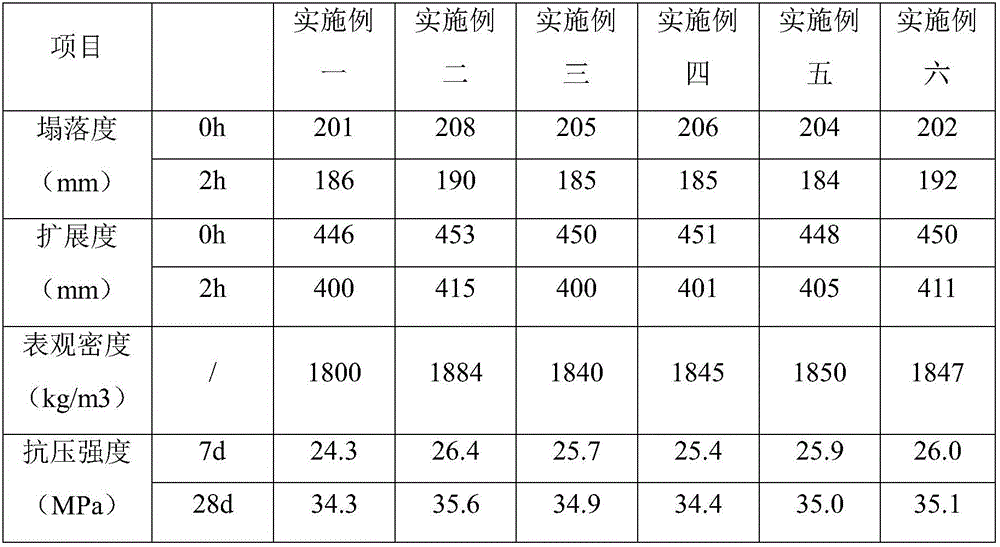

Examples

Embodiment 1

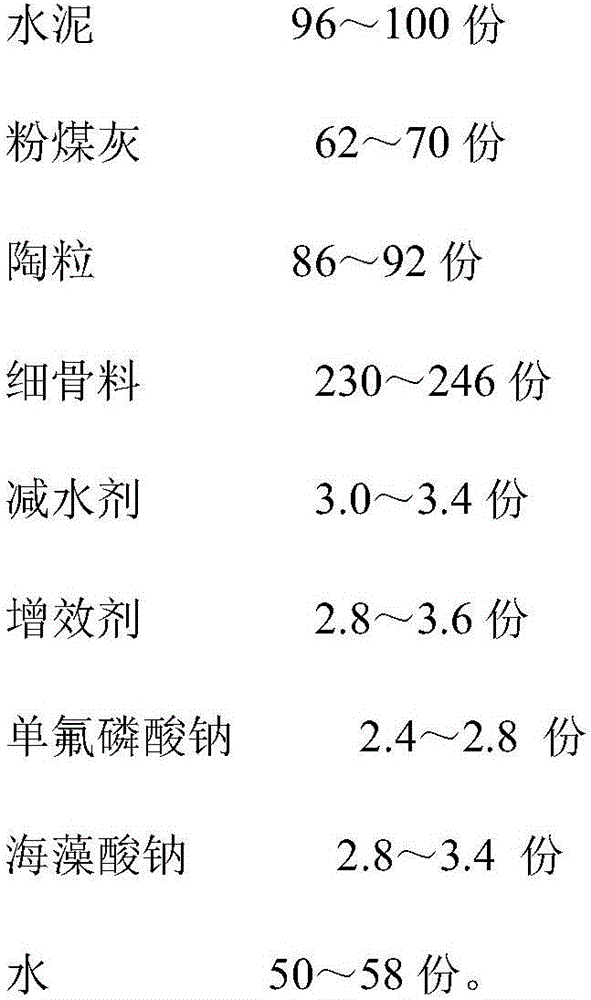

[0032] Step 1: Weigh 1.5kg polycarboxylate retarding high-efficiency superplasticizer and 1.5kg tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare;

[0033] Step 2: Weigh 96kg of cement, 62kg of fly ash, 43kg of bauxite ceramsite, 43kg of coal gangue ceramsite, 104.5kg of natural river sand, 125.5kg of machine-made sand and 50kg of water and add them to the mixing mixer, and use 300rpm Stir at a rotating speed, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 45 minutes;

[0034] Step 3: Weigh 1.4kg of CTF synergist, 1.4kg of LBD synergist, 2.4kg of sodium monofluorophosphate and 2.8kg of sodium alginate into the mixing mixer in step 2, and stir at a speed of 300rpm for another 10min. Thus the finished product is obtained.

[0035] Among them, bauxite ceramsite and gangue ceramsite are both 5-25mm continuous...

Embodiment 2

[0037] Step 1: Weigh 1.14kg polycarboxylate retarding high-efficiency superplasticizer and 2.26kg tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare;

[0038] Step 2: Weigh 100kg of cement, 70kg of fly ash, 36.8kg of bauxite ceramsite, 55.2kg of coal gangue ceramsite, 107kg of natural river sand, 139kg of machine-made sand and 58kg of water into the mixing mixer, and use 300rpm Stir at a rotating speed, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 45 minutes;

[0039] Step 3: Weigh 1.44kg of CTF synergist, 2.16kg of LBD synergist, 2.8kg of sodium monofluorophosphate and 3.4kg of sodium alginate into the mixing mixer in step 2, and stir at a speed of 300rpm for another 10min. Thus the finished product is obtained.

[0040]Among them, bauxite ceramsite and gangue ceramsite are both 5-25mm continuous graded...

Embodiment 3

[0042] Step 1: Weigh 1.28kg polycarboxylate retarding high-efficiency superplasticizer and 1.92kg tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare;

[0043] Step 2: Weigh 98kg of cement, 66kg of fly ash, 38.7kg of bauxite ceramsite, 50.3kg of coal gangue ceramsite, 105.8kg of natural river sand, 132.2kg of machine-made sand and 54kg of water into the mixer, and Stir at a speed of 300rpm, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 45min;

[0044] Step 3: Weigh 1.28kg of CTF synergist, 1.92kg of LBD synergist, 2.6kg of sodium monofluorophosphate and 3.1kg of sodium alginate into the mixing mixer in step 2, and stir at a speed of 300rpm for another 10min. Thus the finished product is obtained.

[0045] Among them, bauxite ceramsite and gangue ceramsite are both 5-25mm continuous graded gravel, density g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com