Method for preparing high strength waterproof nano micropore insulation board

A nano-microporous and waterproof technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of poor formability, reduced bonding effect, insufficient and other problems, and achieve reduced processing costs, improved mechanical strength, and improved mechanical strength. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of high-strength waterproof nano-porous thermal insulation board includes the following steps:

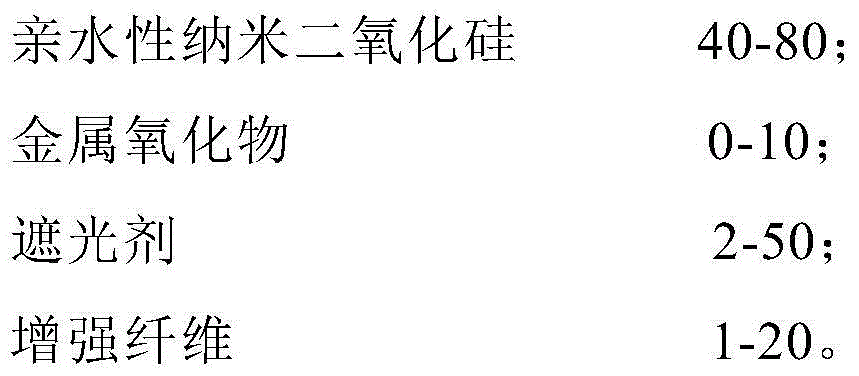

[0045] (a) The hydrophilic microporous heat-insulating material composition is mixed at a high speed in a high-speed mixer, and then molded in a mold by a press to obtain a hydrophilic microporous heat-insulating molding material;

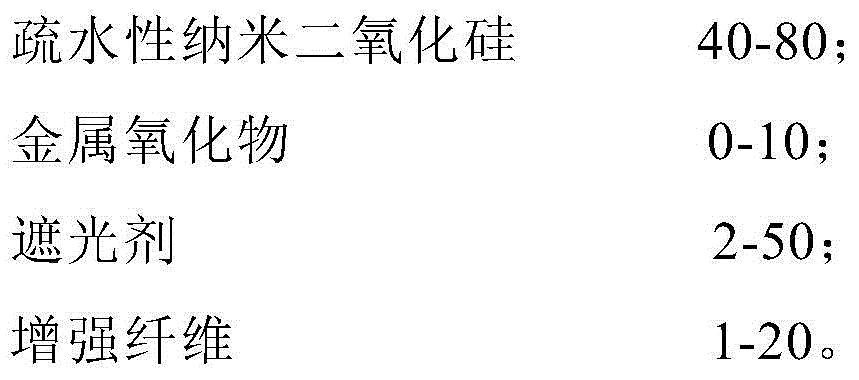

[0046] (b) The hydrophobic microporous thermal insulation material composition is mixed at a high speed in a high-speed mixer, and then molded in a mold by a press to obtain a hydrophobic microporous thermal insulation molding material;

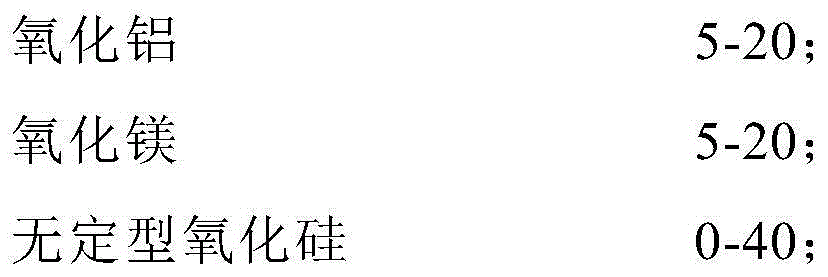

[0047] (c) The room temperature curing phosphate microporous thermal insulation material surface coating composition is placed on the surface of the hydrophilic microporous thermal insulation molding material or the hydrophobic microporous thermal insulation molding material by one-component dip coating method or two-component spray coating method, It can be cured at room temperature to obtain a ...

Embodiment 1

[0070] The one-component composition is spread on a plastic film to form a one-component liquid film about 1 mm thick. Place one surface of the hydrophilic microporous thermal insulation board in Comparative Example 1 gently on the liquid film, confirm that the surface is dip-coated completely, and then perform dip-coating on the reverse side. It can be surface-dried within 30 minutes, and test evaluation is carried out after 24 hours. The results are shown in Table 5.

Embodiment 2

[0072] A two-component paint spray gun was used to spray a two-component composition prepared by mixing components A and B at a weight ratio of 1:1 on the surface of the hydrophilic microporous thermal insulation board of Comparative Example 1 placed upright. After spraying the front side, spray the back side. The board can be surface-dried within 30 minutes of spraying and used for evaluation after 24 hours. The results are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com