Application of calcined kaolin and titanium dioxide in paints

A technology for calcining kaolin and titanium dioxide, applied in the direction of coating, can solve the problems of low whiteness, poor dispersibility, poor covering ability, etc., and achieve the effects of large specific surface area, good rheology, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

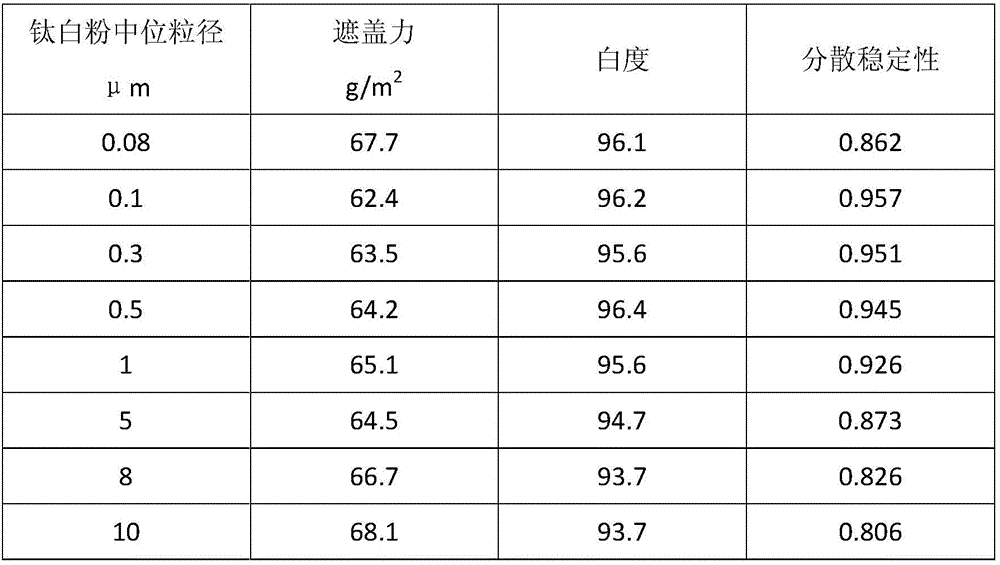

[0025] Industrial titanium dioxide with different particle size distribution was used as filler to prepare finished coatings, and relevant indicators of coatings were tested, and other parameters in the process were taken as intermediate values.

[0026] Table 1 Effect of titanium dioxide with different particle sizes on coating properties

[0027]

[0028] Note: relevant assay methods in the present invention are all measured according to the following methods:

[0029] According to the GB / T 1726-1979 standard to test the hiding power of the paint;

[0030] Test the whiteness of paint according to GB / T 5950-2008 standard;

[0031] Determination of the dispersion stability of the coating: take 50ml of the coating and pour it into a stoppered scale test tube and let it stand, read the volume V of the supernatant after 48 hours, then the dispersion stability of the coating = (50-V) / 50, where the larger the value Indicates that the dispersion stability of the paint is better...

experiment example 2

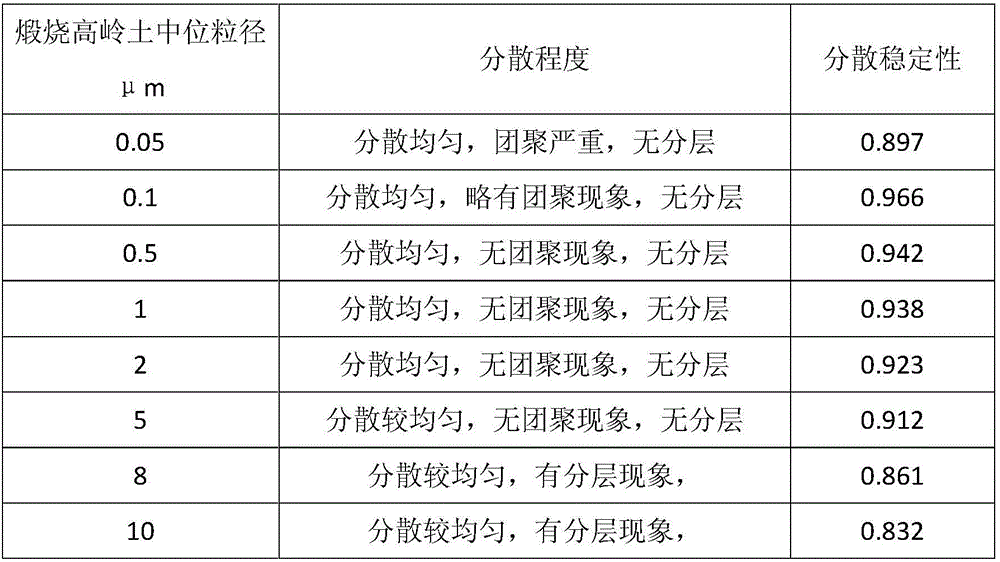

[0034] Industrial calcined kaolin with different particle size distributions was taken, and other parameters in the process were taken as intermediate values, and coatings were prepared and related tests were carried out. The results are shown in Table 2.

[0035] Table 2 Effects of calcined kaolin with different particle sizes on coating properties

[0036]

[0037] It can be seen from Table 2 that when the median particle size of calcined kaolin exceeds 5 μm, its dispersion in the coating is poor, and its dispersion is unstable, and when it is less than 0.1um, it is easy to agglomerate and the dispersibility is not good. Therefore, the present invention chooses Particle size satisfies 0.1um≤D 50高岭土 Calcined kaolin ≤5um was used as the experimental raw material.

experiment example 3

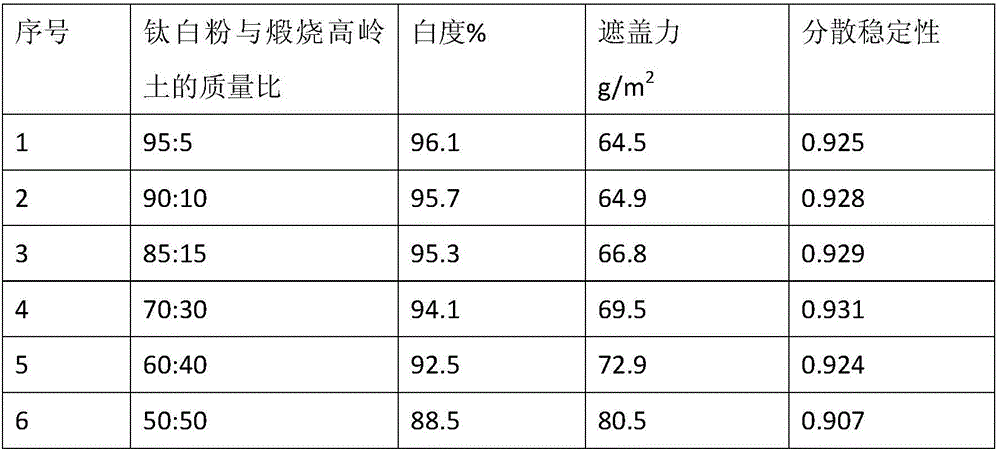

[0039] Take industrial titanium dioxide with a median particle size of 1 μm and industrial calcined kaolin with a median particle size of 1 μm, and obtain different numbers of compositions by mixing calcined kaolin and titanium dioxide with different mass ratios, and make coatings and test their key Index, other parameters in the process take intermediate values.

[0040] Table 3 Effect of different mass ratios of titanium dioxide and calcined kaolin on coating properties

[0041]

[0042] As shown in Table 3, as the amount of calcined kaolin increased, the whiteness and hiding power of the paint decreased significantly. When the amount of calcined kaolin added exceeded 40%, the whiteness and hiding power of the paint decreased significantly, which could not meet the requirements. Therefore, in the present invention, the mass ratio of titanium dioxide to calcined kaolin is 60%-95%: 40%-5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com