Ceramic tile formed by dry pressure slip casting and production method thereof

A technology of grouting molding and production method, which is applied in the field of building ceramics production, can solve the problems of low glaze surface smoothness of finished ceramic tiles, difficult brick powder particles, drying and cracking, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

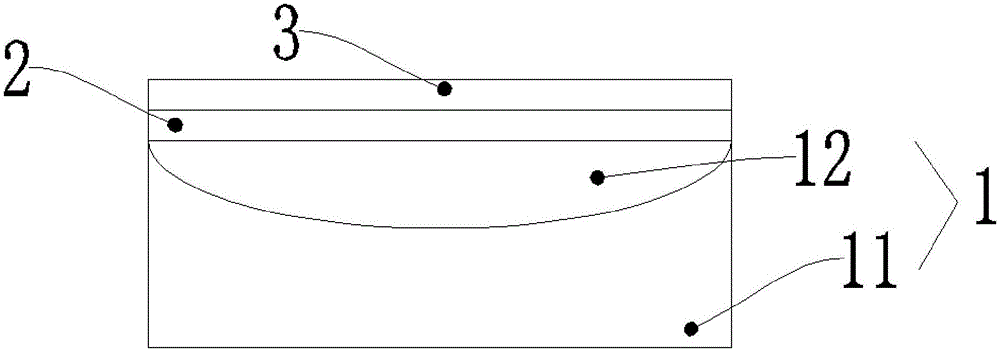

[0037] The dry pressure grouting ceramic brick of the present embodiment comprises green body 1, as figure 1 As shown, the body 1 includes an adobe layer 11 and a facing layer 12, and the upper surface of the adobe layer 11 has a concave cavity depressed downward;

[0038] The fabric layer 12 is arranged on the upper surface of the brick layer 11 , and the fabric layer 12 fills up the cavity of the brick layer 11 .

[0039] The dry forming process of architectural ceramics is to dry granulate the ground ceramic powder and pour it into a pressing mold, and then press it into a brick by a stamping machine. Because the shape of the ceramic powder particles formed by dry granulation is mostly cones and cylinders with different particle sizes, it does not form uniform spherical particles like traditional spray granulation; so that the pressed bricks have powder. Material particles are not easy to control, rough surface and other defects, and then lead to problems such as low smoot...

Embodiment 2

[0066] The production method of the dry pressure grouting ceramic brick of the present embodiment may further comprise the steps:

[0067] Step 1, calculated in parts by mass, weighed 10 parts of clay, 38 parts of silt, 51 parts of feldspar and 1.2 parts of ceramic additives, dry granulated and pressed into an adobe with a concave cavity on the upper surface, and the concave cavity The depth of the center depression is 4.5mm, and the edge thickness of the adobe is 11mm;

[0068] Step 2, firing the adobe in step 1 at 1020° C. for 30 minutes to obtain a biscuit;

[0069] Step 3: Calculate by mass parts, weigh 10 parts of clay, 38 parts of silt, 51 parts of feldspar and 1.2 parts of ceramic additives, mix and ball mill them into a slurry with a fineness of 300 mesh sieve and a sieve residue of 3-4g / 100ml ;

[0070] Step 4, inject the slurry obtained in step 3 into the concave cavity of the biscuit body obtained in step 2 through the glaze pourer, and the slurry should fill up t...

Embodiment 3

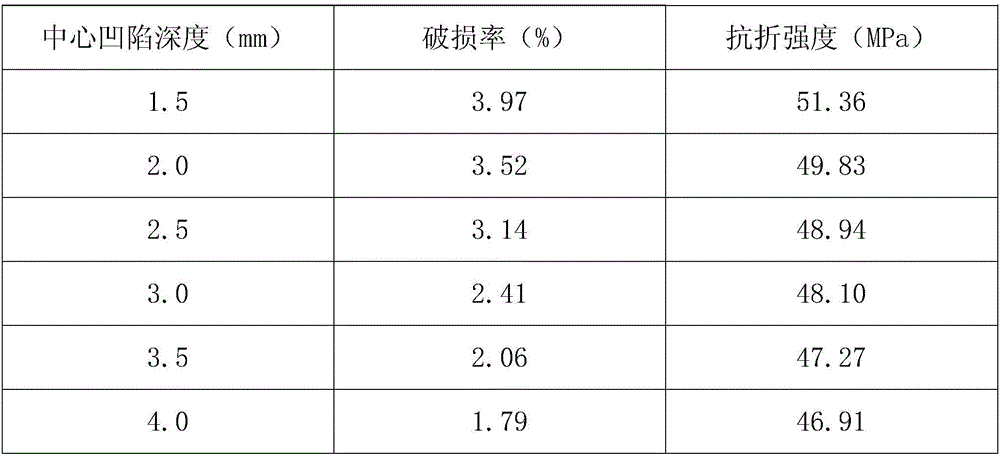

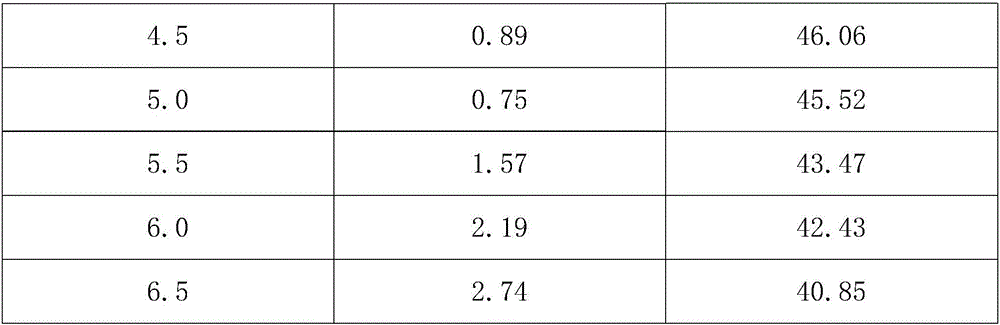

[0076] According to the production method of the dry pressure grouting ceramic brick described in embodiment 1, the ceramic bricks with different depths of the center depression of the concave cavity of the adobe layer 11 are made, and 1000 pieces of ceramic bricks with each center depression depth are produced, and Comparing the breakage rate and flexural strength of ceramic tiles with each center depression depth, the results are shown in Table 1 below:

[0077]

[0078]

[0079] Table 1

[0080] As can be seen from Table 1, when the central depression depth of the concave cavity of the described brick layer 11 is too small, the stress dispersion effect of the described brick layer 11 is not obvious, and the damage rate of the finished ceramic tile is high; when the central depression depth is too large,

[0081] If the thickness of the adobe layer 11 is too small, the strength will decrease and breakage will easily occur. Therefore, the central depression depth of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com