Organic electrode material of organic electrolyte sodium iron battery and preparation method thereof

A sodium-ion battery, organic electrolyte technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited capacity and voltage of electrode materials, and achieve the effect of extending cycle life, increasing capacity, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

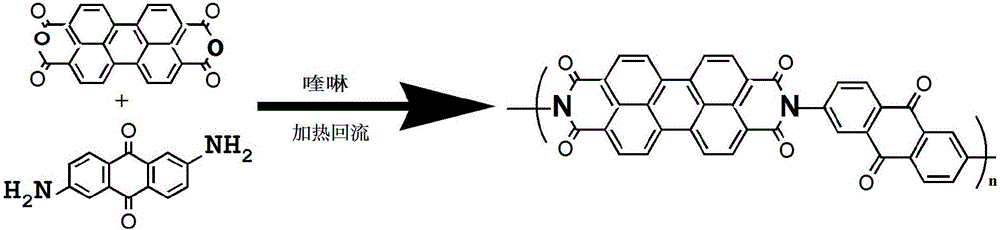

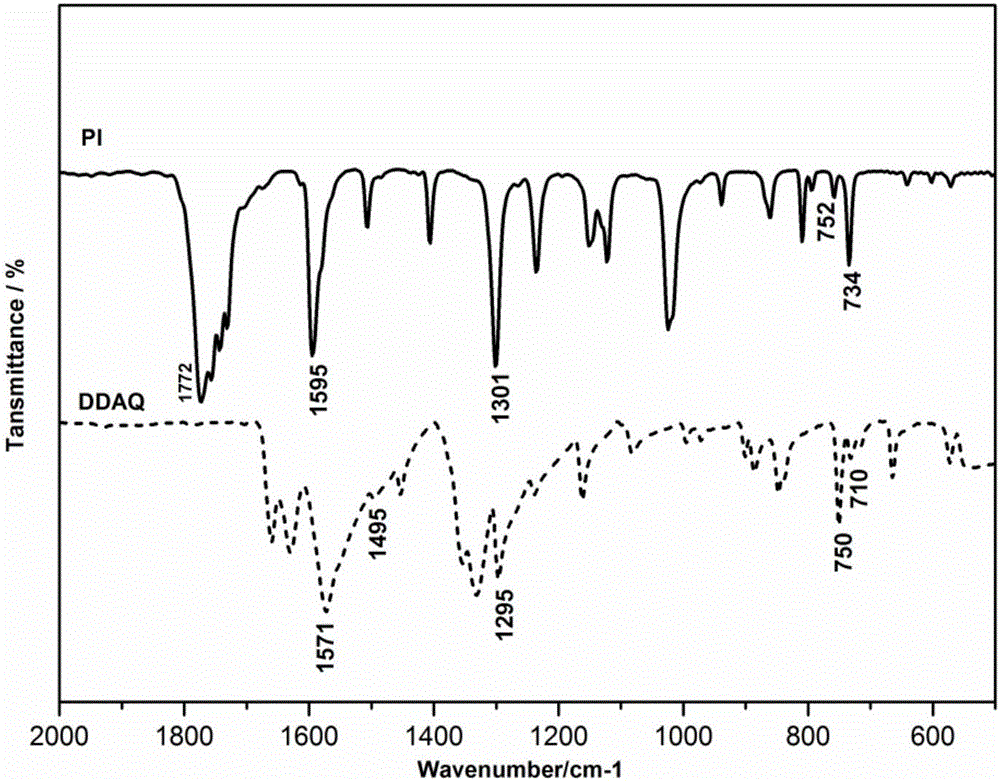

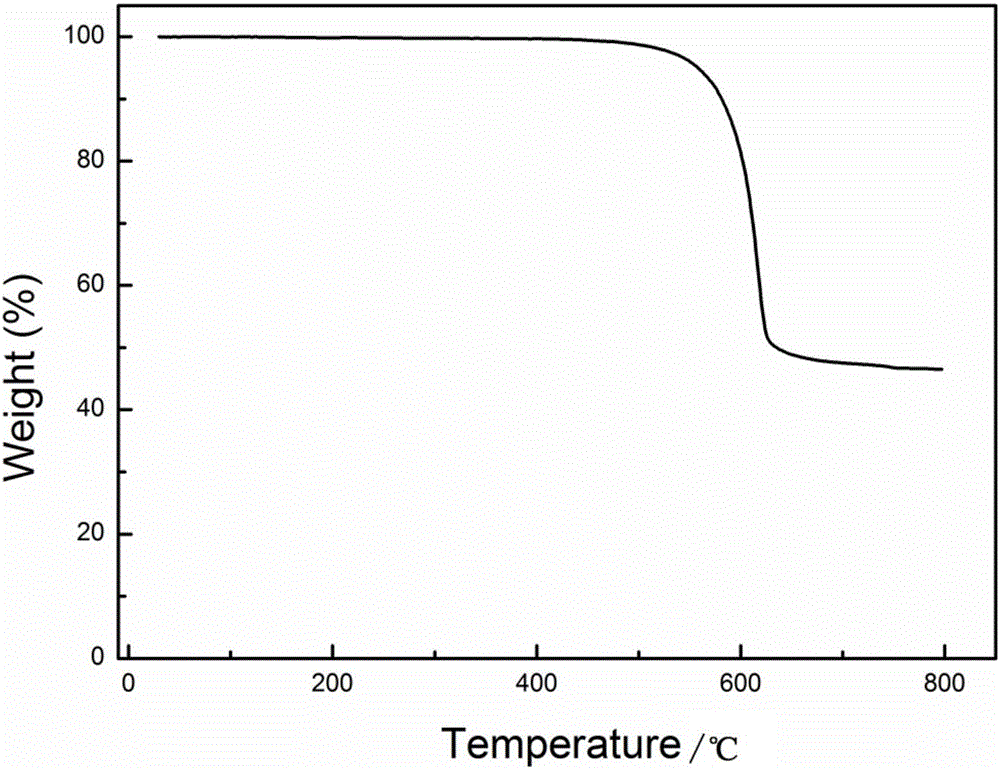

[0046] figure 1 It is a synthesizing schematic diagram of an organic electrode material of the embodiment of the present invention, such as figure 1 Shown, a kind of preparation method of organic electrode material comprises the following steps:

[0047] S1: Add an aprotic solvent to the container, place the container in an oil bath environment, pass inert gas, add a condensing device, and pass in circulating cooling water;

[0048] S2: adding an acid anhydride and an electrochemically active diamine to the aprotic solvent described in step S1 in sequence, and stirring at room temperature for 8-12 hours;

[0049] S3: The uniformly stirred mixture in S2 is gradually heated from room temperature to a certain temperature in the range of 200°C to 250°C, and kept at this temperature for 6 to 12 hours under reflux, then stop heating and cool to room temperature;

[0050] S4: The mixture obtained in step S3 is suction filtered, and washed with dimethylformamide ethanol, an aprotic ...

Embodiment 1

[0059] S1: Add 50mL quinoline into a 150mL three-necked flask, place the three-necked flask in an oil bath environment, pass nitrogen gas to add a condensing device and circulate cooling water.

[0060] S2: Add perylenetetracarboxylic dianhydride (PTCDA) and 2,6-diaminoanthraquinone (DDAQ) sequentially to the quinoline solution described in step S1, and stir at room temperature for 8 h.

[0061] The ratio of the amount of substances of PTCDA and DDAQ satisfies the following relationship:

[0062] n(PTCDA):n(DDAQ)=1:0.8

[0063] S3: The homogeneously stirred mixture in S2 was gradually heated from room temperature to 250° C., kept at this temperature and heated to reflux for 12 h, turned off the heating and cooled to room temperature.

[0064] S4: The mixture obtained in step S3 is suction-filtered, and repeatedly washed with ethanol, dimethylformamide (DMF), n-methylpyrrolidone (NMP) and deionized water until the filtrate is basically colorless, and the suction-filtered The ...

Embodiment 2

[0068] S1: Add 50ml of quinoline into a 150ml three-necked flask, place the three-necked flask in an oil bath environment, pass nitrogen gas to add a condensing device and circulate cooling water.

[0069] S2: Add perylenetetracarboxylic dianhydride (PTCDA) and 2,6-diaminoanthraquinone (DDAQ) sequentially to the NMP solution described in step S1, and stir at room temperature for 10 h.

[0070] The ratio of the amount of substances of PTCDA and DDAQ satisfies the following relationship:

[0071] n(PTCDA):n(DDAQ)=1:1

[0072] S3: The homogeneously stirred mixture in S2 was gradually heated from room temperature to 230° C., and kept at this temperature for 8 h under reflux, then turned off the heating and cooled to room temperature.

[0073] S4: The mixture obtained in step S3 is suction-filtered, and repeatedly washed with ethanol, dimethylformamide (DMF), N-methylpyrrolidone (NMP) and deionized water until the filtrate is basically colorless, and the suction-filtered The powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com