Anti-pollution polyvinylidene fluoride hollow-fiber membrane and preparation method thereof

A technology of polyvinylidene fluoride and fiber membrane, which is applied in the field of new high anti-pollution polyvinylidene fluoride hollow fiber membrane and its preparation, can solve the problems of less research on zwitterions, achieve effective retention rate and strong resistance to protein adsorption Ability to ensure the effect of stable flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

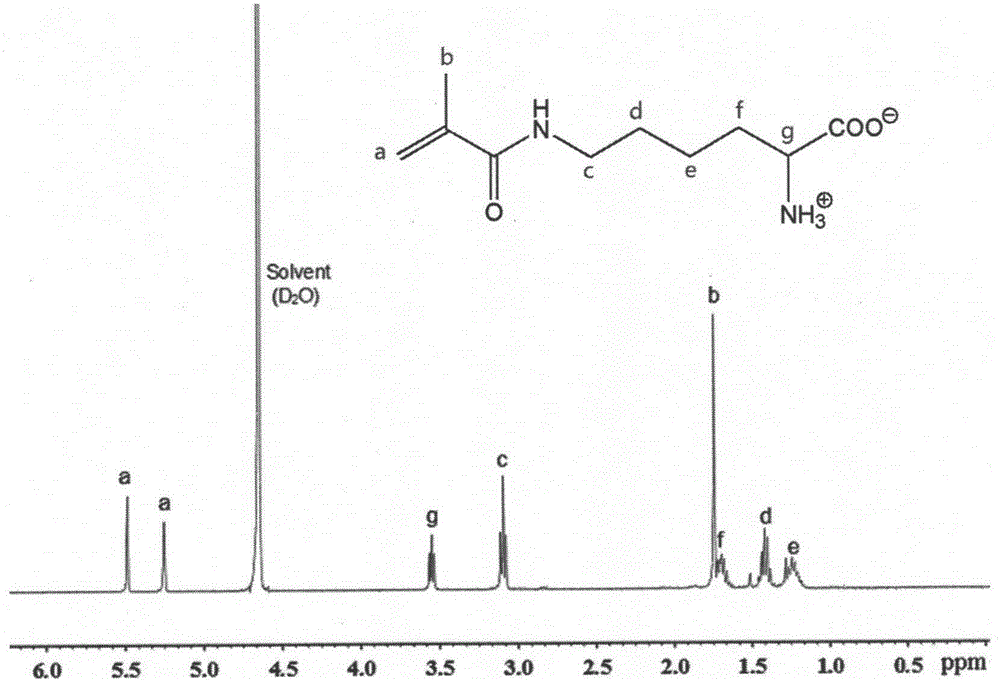

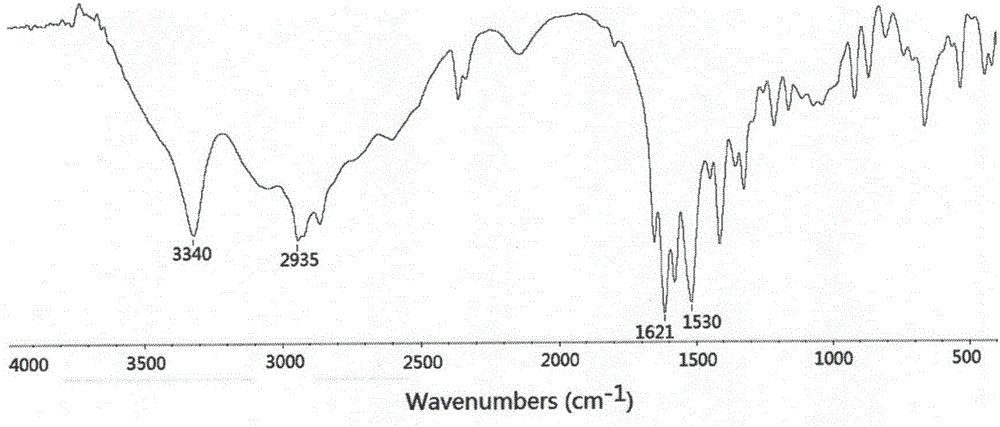

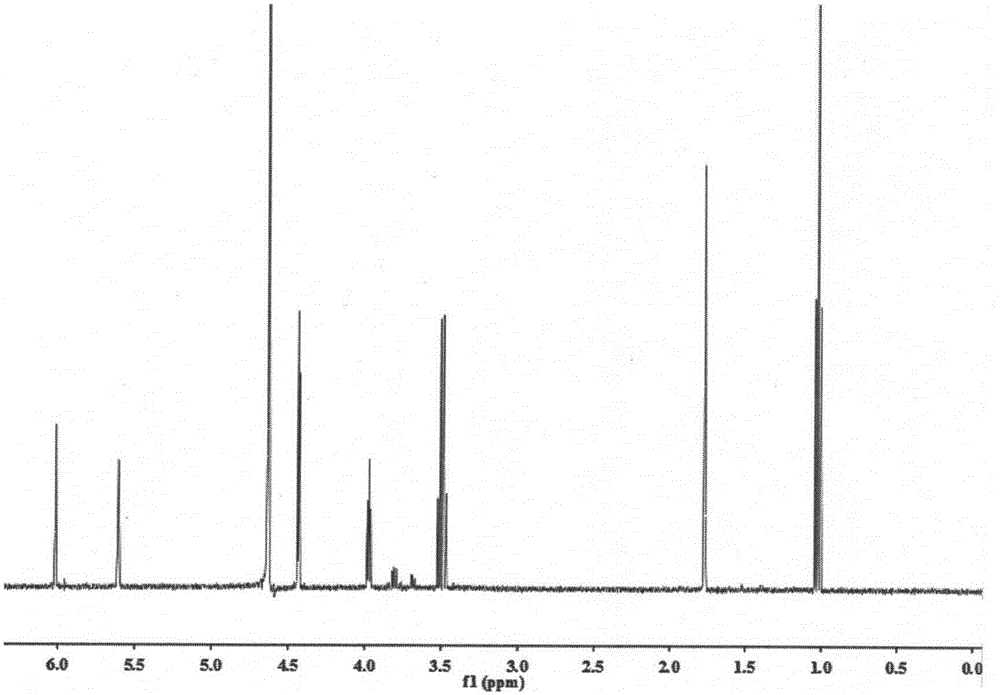

Method used

Image

Examples

Embodiment 1

[0055] An anti-pollution polyvinylidene fluoride hollow fiber membrane is a polyvinylidene fluoride hollow fiber membrane with amphoteric ionization of amino acids. The preparation method of the anti-pollution polyvinylidene fluoride hollow fiber membrane is:

[0056] The first step: introducing active sites: immerse the polyvinylidene fluoride hollow fiber membrane in a 1.8mol / L lithium hydroxide aqueous solution, perform the first ultrasonic oscillation at 100% rated power for 1min, stir and react at 80°C for 24h, and then Wash with water, dry, then immerse in 0.078mol / L sodium borohydride solution (solvent is isopropanol), carry out the second ultrasonic oscillation at 100% rated power for 20min, stir at room temperature for 24h, wash with water, dry, add diiso In butyl aluminum hydride, ultrasonically treat for 20 minutes at 100% rated power, react at room temperature for 65 hours, wash and dry with water to obtain a hollow fiber membrane (PVDF-OH) with surface hydroxylati...

Embodiment 2

[0063] An anti-pollution polyvinylidene fluoride hollow fiber membrane is a polyvinylidene fluoride hollow fiber membrane with amphoteric ionization of amino acids. The preparation method of the anti-pollution polyvinylidene fluoride hollow fiber membrane is:

[0064] The first step: introducing active sites: immerse the polyvinylidene fluoride hollow fiber membrane in a 1.8mol / L lithium hydroxide aqueous solution, perform the first ultrasonic oscillation at 100% rated power for 10 minutes, stir and react at 80°C for 1 hour, and then Wash with water, dry, then immerse in 0.078mol / L sodium borohydride solution (solvent is isopropanol), carry out the second ultrasonic oscillation at 100% rated power for 20min, stir at room temperature for 24h, wash with water, dry, add diiso In butyl aluminum hydride, ultrasonically treat for 20 minutes at 100% rated power, react at room temperature for 65 hours, wash and dry with water to obtain a hollow fiber membrane (PVDF-OH) with surface hy...

Embodiment 3

[0069] An anti-pollution polyvinylidene fluoride hollow fiber membrane is a polyvinylidene fluoride hollow fiber membrane with amphoteric ionization of amino acids. The preparation method of the anti-pollution polyvinylidene fluoride hollow fiber membrane is:

[0070] The first step: introducing active sites: immerse the polyvinylidene fluoride hollow fiber membrane in a 1.8mol / L lithium hydroxide aqueous solution, perform the first ultrasonic oscillation for 5 minutes at 100% rated power, stir and react at 80°C for 6 hours, and then Wash with water, dry, then immerse in 0.078mol / L sodium borohydride solution (solvent is isopropanol), carry out ultrasonic oscillation for 20min for the second time at 100% rated power, stir at room temperature for 1h, wash with water, dry, add diiso In butyl aluminum hydride, ultrasonically treat for 20 minutes at 100% rated power, react at room temperature for 65 hours, wash and dry with water to obtain a hollow fiber membrane (PVDF-OH) with su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com