Preparation method for nano silicon dioxide

A nano-silica and aqueous solution technology, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of complex preparation steps, non-continuous production, slow production speed, etc., and achieve fast preparation speed and adaptability Strong performance and good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

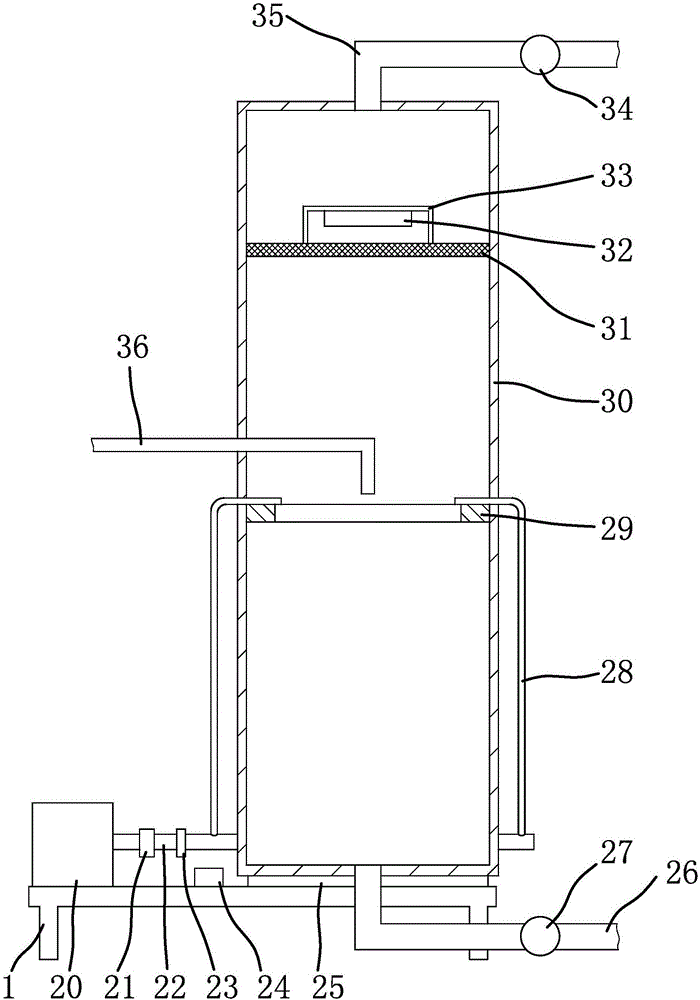

[0057] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0058] The preparation method of this nano silicon dioxide comprises the following steps:

[0059] a. Preparation: prepare a 7.5% NaCl aqueous solution and a 45% NaCl solution with high-purity water 2 SiO 3 Aqueous solution and concentration are 13.5% dilute hydrochloric acid solution; In the present embodiment, high-purity water adopts the existing product that can buy on the market;

[0060] B, reaction: the NaCl aqueous solution, NaCl prepared in step a 2 SiO 3 The aqueous solution and dilute hydrochloric acid solution are poured into the reactor for reaction, and the reaction time is 10-40min. In this embodiment, the reaction time is 25min;

[0061] c. Aging: introducing the reacted solution in the reactor into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com