System and method for advanced treatment of industrial sewage

A technology for industrial sewage and advanced treatment, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. and other problems, to achieve the effect of excellent decolorization effect, stable treated water and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

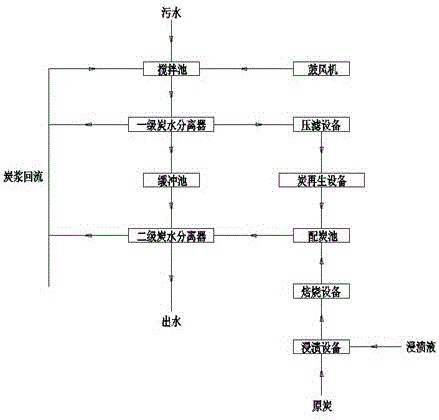

[0039] please see figure 1 , a system for advanced treatment of industrial sewage provided by the present invention, including a carbon distribution tank, a stirring tank, a blower, a primary carbon-water separator (air flotation tank or sedimentation tank), a buffer tank, a secondary carbon-water separator (tank type Filter tube filter separator), filter press equipment, carbon regeneration equipment, impregnation equipment, roasting equipment; industrial sewage treatment plant tail water is sent into the mixing tank for full mixing with powdered activated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com