Ammonia and methanol synthesizing system

A technology for synthesizing ammonia and methanol, which is applied in the field of synthetic ammonia or methanol systems, can solve the problems of high water vapor consumption, low heat utilization rate, and large power consumption, so as to reduce the input volume, improve the utilization rate, and eliminate the generation of waste water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

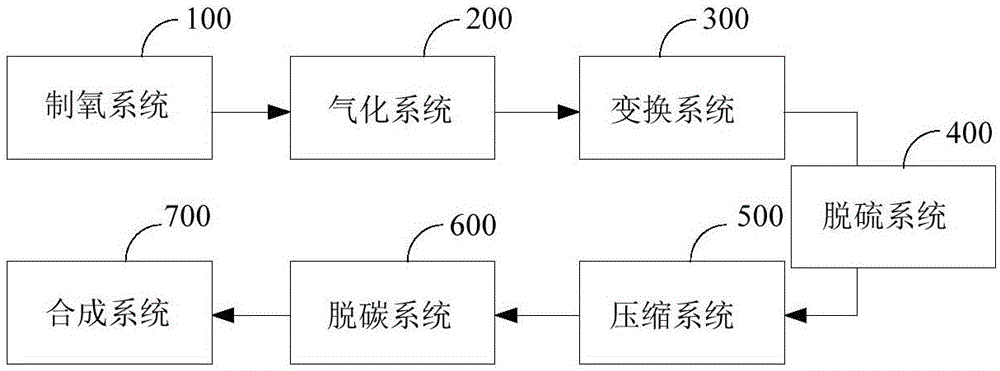

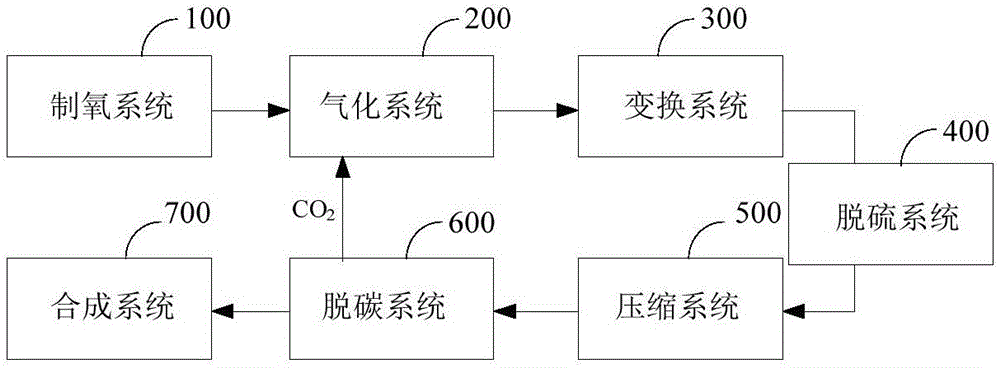

[0046] Such as Figure 1-6 As shown, the synthetic ammonia or methanol system provided by the embodiment of the present invention includes: an oxygen production system 100, a gasification system 200, a conversion system 300, a desulfurization system 400, a compression system 500, a decarbonization system 600 and a synthesis system 700; in:

[0047] The oxygen generating system 100 is cryogenic air separation oxygen generating equipment or pressure swing adsorption oxygen generating equipment; The air blower 104 , the pressure swing adsorption air separation oxygen generator 101 and the gas-making air blower 104 are all connected to the oxygen-enriched mixing tank 102 , and the oxygen-enriched mixing tank 102 is connected to the gasification system 200 .

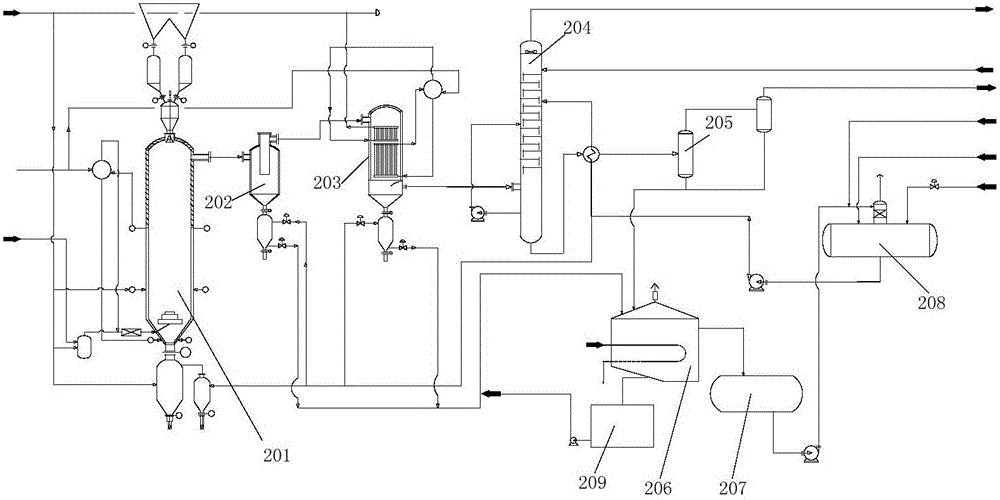

[0048] The gasification system 200 includes a gasification reaction furnace 201 for continuous gasification at a pressure of 0.1 MPa to 1.5 MPa. The furnace wall of the gasification reaction furnace 201 is a semi-jacket stru...

Embodiment 2

[0074] Embodiment 2 provides another system for synthesizing ammonia or methanol, including: an oxygen production system 100, a gasification system 200, a conversion system 300, a desulfurization system 400, a compression system 500, a decarbonization system 600 and a synthesis system 700 connected in sequence; in:

[0075] The oxygen generation system 100 is deep space air separation oxygen generation equipment or pressure swing adsorption oxygen generation equipment. The pressure swing adsorption oxygen generation equipment includes: pressure swing adsorption air separation oxygen generation machine 101, oxygen enriched mixing tank 102, compression device 103 and gas generation air Blower 104 , pressure swing adsorption air separation oxygen generator 101 and gas-making air blower 104 are all connected to oxygen-enriched mixing tank 102 , and oxygen-enriched mixing tank 102 is connected to gasification system 200 .

[0076] The gasification system 200 includes a gasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com