Three-dimensional high-strength fabric with memory function and preparation method thereof

A three-dimensional, functional technology, applied in the field of textile materials, can solve the problems that are difficult to apply to the civilian field, and there are few researches on three-dimensional fabrics, and achieve the effects of improving UV resistance, strong operability, and increasing bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

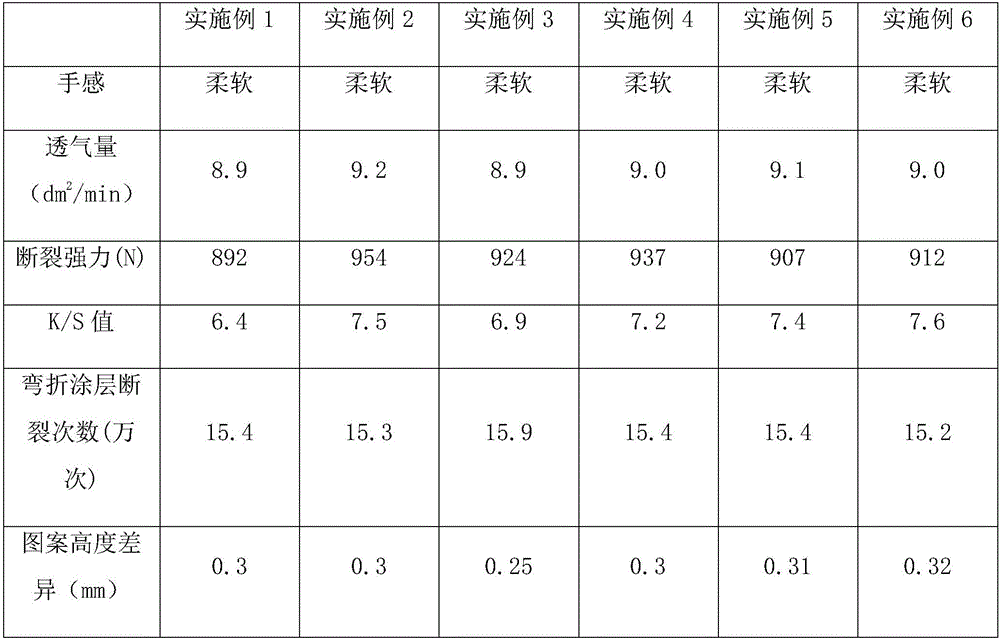

Examples

Embodiment 1

[0029] (1) Using silk fiber with a yarn root number ratio of 10:10:4:5:5, polyester superfine fiber, nylon fully drawn yarn, shape memory alloy wire and PBT / PET three-dimensional crimped fiber as raw materials, in weft Weaving on a knitting machine to form a three-dimensional fabric with a thickness of 1 cm.

[0030] (2) Add the high molecular polymer of water-soluble polyurethane and water-based epoxy resin with a mass ratio of 1:1 into deionized water, stir evenly to form a solution A, and add a 50-200nm nanometer with a mass ratio of 1:1:0.5 Titanium dioxide, 100-200nm nano-silica, nano-materials with a mass fraction of 3% nano-silk protein solution, and plant-derived dyes are added containing polyvinyl ether, polyethylene glycol and dodecane with a mass ratio of 1:0.8:0.5. In the deionized aqueous solution of sodium sulfate surfactant, mix uniformly to form solution B, slowly add solution B in solution A, stir rapidly, and dropwise add pH adjuster ammonia water, obtain nan...

Embodiment 2

[0033] (1) Using silk fiber with a yarn root number ratio of 15:10:6:9:10, polyester superfine fiber, nylon fully drawn yarn, shape memory alloy wire and PBT / PET three-dimensional crimped fiber as raw materials, in weft Weaving on a knitting machine to form a three-dimensional fabric with a thickness of 2 cm.

[0034] (2) Add the high molecular polymer of water-soluble polyurethane and water-based epoxy resin with a mass ratio of 1:1 into deionized water, stir evenly to form a solution A, and add a 50-200nm nanometer with a mass ratio of 1:1:0.5 Titanium dioxide, 100-200nm nano-silica, nano-materials with a mass fraction of 5% nano-silk protein solution and plant-derived dyes are added with polyvinyl ether, polyethylene glycol and dodecane with a mass ratio of 1:1.2:0.6 In the deionized aqueous solution of sodium sulfate surfactant, mix uniformly to form solution B, slowly add solution B in solution A, stir rapidly, and dropwise add pH adjuster ammonia water, obtain nanomateri...

Embodiment 3

[0037] (1) Using silk fiber with a yarn root number ratio of 12:10:5:7:8, polyester superfine fiber, nylon fully drawn yarn, shape memory alloy wire and PBT / PET three-dimensional crimped fiber as raw materials, in weft Weaving on a knitting machine to form a three-dimensional fabric with a thickness of 1.5 cm.

[0038] (2) Add the high molecular polymer of water-soluble polyurethane and water-based epoxy resin with a mass ratio of 1:1 into deionized water, stir evenly to form a solution A, and add a 50-200nm nanometer with a mass ratio of 1:1:0.5 Titanium dioxide, 100-200nm nano-silica, nano-materials with a mass fraction of 4% nano-silk protein solution and plant-derived dyes are added with polyvinyl ether, polyethylene glycol and dodecane with a mass ratio of 1:1:0.5 In the deionized aqueous solution of sodium sulfate surfactant, mix uniformly to form solution B, slowly add solution B in solution A, stir rapidly, and dropwise add pH adjuster ammonia water, obtain nanomateria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com