Continuous analysis method of calcium fluoride and silicon dioxide in fluorite

A technology of silica and medium calcium fluoride, which is applied in the field of fluorite analysis, can solve the problems of affecting the analysis speed, increasing the analysis cost, and strong dependence on standard samples, so as to improve production efficiency, simple equipment, and high accuracy of results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

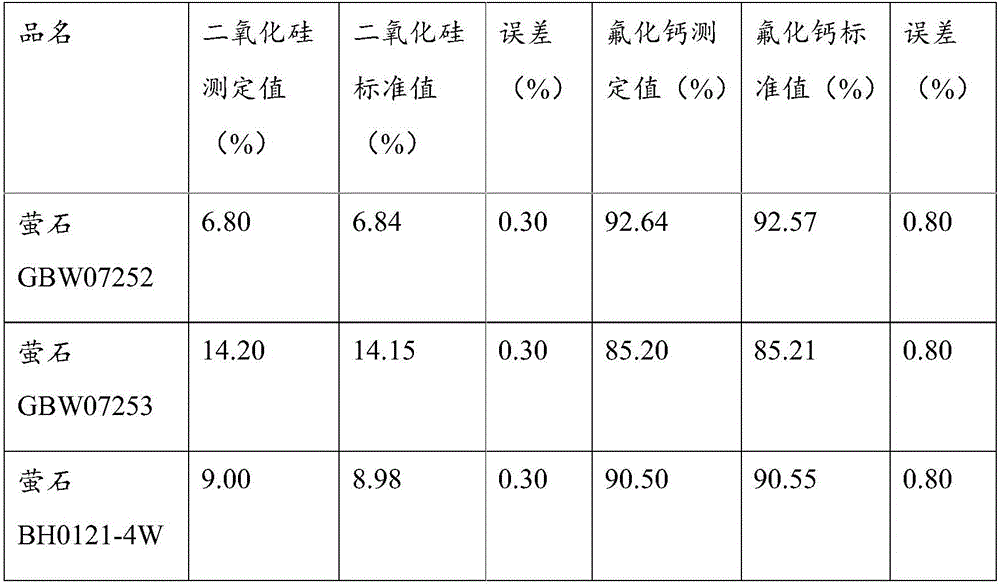

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the preferred embodiments of the present invention. Based on the embodiments in this application, those of ordinary skill in the art will Other similar embodiments obtained without creative work shall all fall within the scope of protection of this application.

[0027] Continuous method for the analysis of calcium fluoride and silica in fluorspar, including:

[0028] Step 1: Dissolve the fluorite sample with glacial acetic acid, filter with filter paper, place the precipitate in a platinum crucible, carefully ash it in a high-temperature furnace, burn it at 650-700 degrees for 40 minutes, take it out and place it in a desiccator, and cool it After weighing, count the quality of the platinum crucible and silicon dioxide;

[0029] Weigh 0.5000g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com