Preparation method of nitrogen-doped carbon-loaded metal monoatomic catalyst

A metal-loaded, nitrogen-doped carbon technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high cost and complicated process, and achieve the method Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a nitrogen-doped carbon-supported metal single-atom catalyst, comprising the following steps:

[0032] (1) mixing soluble metal salt, hydroxylamine hydrochloride, soluble carbon source, water and ethanol to obtain a mixed solution;

[0033] (2) drying the mixed solution obtained in the step (1) to obtain a catalyst precursor;

[0034] (3) Calcining the catalyst precursor obtained in the step (2) to obtain a nitrogen-doped carbon-supported metal single-atom catalyst.

[0035] The invention mixes soluble metal salt, hydroxylamine hydrochloride, soluble carbon source, water and ethanol to obtain a mixed solution. In the present invention, the molar ratio of the soluble metal salt to hydroxylamine hydrochloride is preferably (0.001~0.01):(0.001~1), more preferably (0.002~0.008):(0.01~0.5), most preferably (0.004 ~0.006): (0.05~0.1).

[0036] In the present invention, the molar ratio of the soluble metal salt to the soluble ca...

Embodiment 1

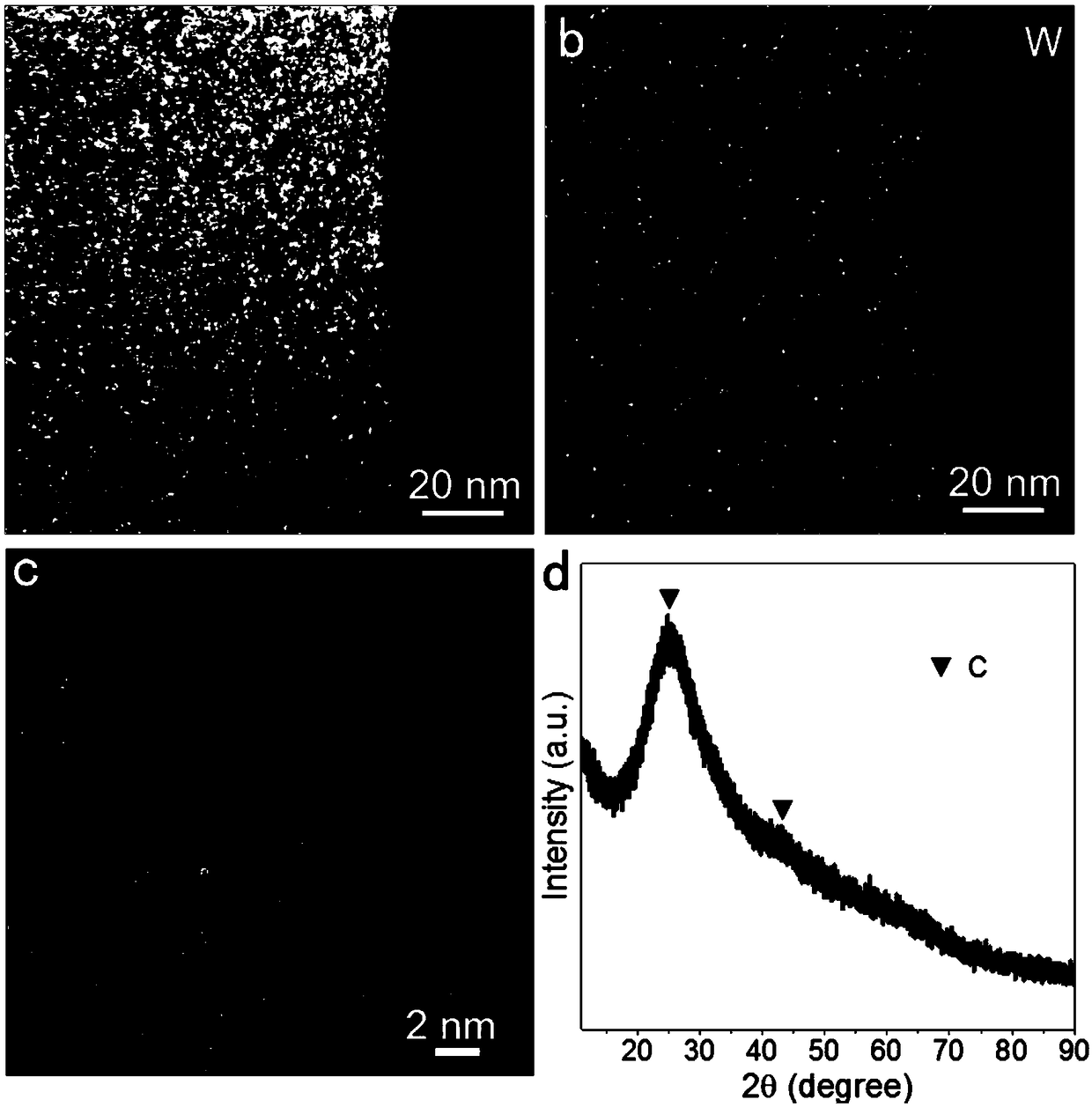

[0049] Synthesis of W single-atom catalyst: using ammonium molybdate, hydroxylamine hydrochloride, and glucose as precursors, and synthesized through the steps of dissolution, precipitation, and calcination, the details are as follows:

[0050] (1) Weigh 0.0111 grams of ammonium tungstate and 0.69 grams of hydroxylamine hydrochloride into a beaker, add 40 milliliters of deionized water, and ultrasonically dissolve them for 5 minutes, then add 40 milliliters of alcohol, and then add 0.0544 grams of anhydrous glucose. After ultrasonically dissolving the mixture, it was dried in an oven at 70 °C.

[0051] (2) Take out the dried sample and put it in a porcelain boat, transfer it to a vacuum tube furnace, feed high-purity argon gas at a rate of 50 ml / min for protection, and turn the vacuum tube furnace at a speed of 5 degrees Celsius / min From room temperature to 600 degrees Celsius, keep warm for 4 hours.

[0052] (3) Cool down to room temperature in a vacuum tube furnace, take ou...

Embodiment 2

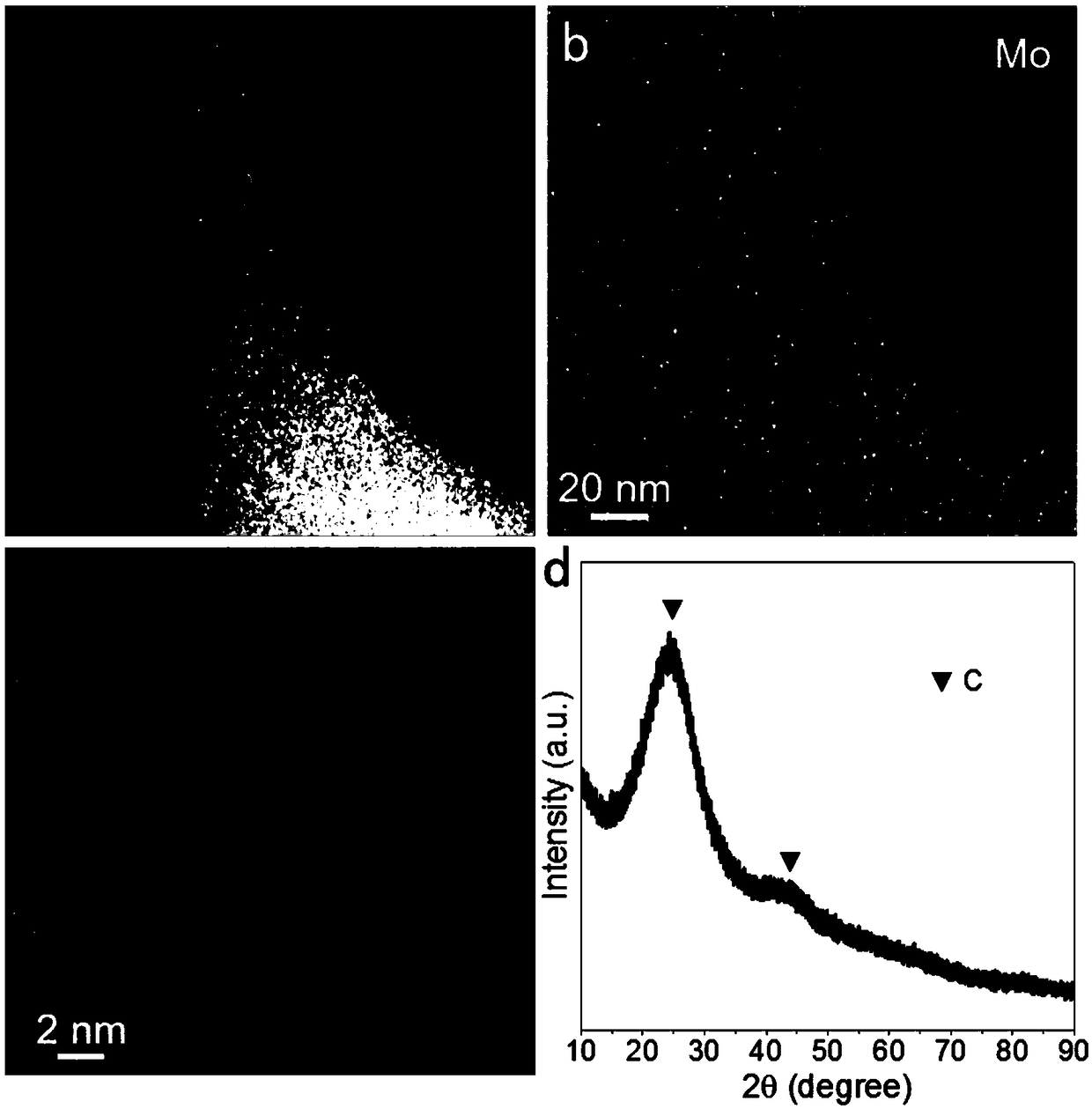

[0055] Synthesis of Mo single-atom catalyst: its synthesis steps are the same as W single-atom catalytic synthesis in Example 1, except that 0.0111 gram of ammonium tungstate is replaced by 0.0155 gram of ammonium molybdate, and the temperature of the vacuum tube furnace is changed to 650 degrees Celsius.

[0056] The nitrogen-doped carbon-supported metal single-atom catalyst prepared in this example is as figure 2 as shown, figure 2 a is the scanning transmission dark field image of Example 2, it can be seen that no obvious agglomerated particles appear, figure 2 b It can be seen that the Mo element is evenly distributed on the substrate, figure 2 c is an atomic resolution high-angle annular dark field image, it can be clearly seen that Mo single atoms are dispersed on the substrate, figure 2 In d, except for the X-ray diffraction peak of carbon element, there are no other crystal diffraction peaks. These results indicate that W element atoms are dispersedly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com