Nitrogen dioxide adsorbent, nitrogen dioxide absorbing device and manufacturing method of nitrogen dioxide absorbing device

A nitrogen dioxide and adsorption device technology, applied in the fields of nitrous oxide capture, alkali metal oxides/hydroxides, chemical instruments and methods, etc., can solve the problems of non-use, achieve uniform pore size distribution, and enhance surface potential energy , the effect of improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

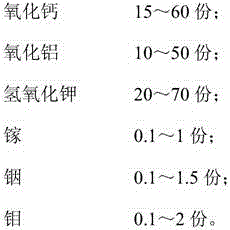

[0053] Embodiment 1~3 prepares raw material by table 1:

[0054] The raw material weight part of table 1 embodiment 1~3

[0055] raw material Example 1 Example 2 Example 3 calcium salt 60 copies 40 copies 15 copies Aluminum salt 10 copies 15 copies 45 copies potassium salt 20 copies 50 copies 65 copies Gallium salt 1 copy 0.5 parts 0.2 parts Indium salt 0.2 parts 1 copy 1.5 servings Molybdenum salt 2 copies 0.5 parts 1 copy

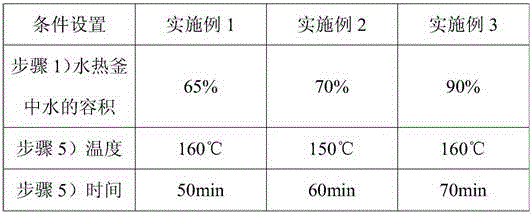

[0056] And according to the parameter adjustment manufacturing method shown in table 2, carry out the manufacture of nitrogen dioxide adsorption device:

[0057] The manufacturing conditions of table 2 embodiment 1~3

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com