A kind of preparation method of high concentration d-arabinose

A technology of arabinose and sugar liquid, applied in the field of functional sugar, can solve the problems of low yield of D-arabinose, high production cost, complicated process, etc., and achieve the effect of simple extraction and crystallization steps, reduced production cost, and rich applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In one embodiment of the present invention, the preparation method of the high-concentration D-arabinose of the present invention comprises the following steps:

[0025] 1), adding a catalyst to the sodium gluconate solution, adding hydrogen peroxide and sodium gluconate, and oxidizing to prepare D-arabinose solution;

[0026] 2), refined to obtain D-arabinose liquid;

[0027] 3) Crystallization to prepare D-arabinose crystals.

[0028] In one embodiment of the present invention, in the method for preparing high-concentration D-arabinose of the present invention, the catalyst in the above step 1) is a soluble iron salt. More preferably, in yet another embodiment of the present invention, in the method for preparing high-concentration D-arabinose in the present invention, the catalyst in step 1) is ferric chloride, ferrous sulfate, and ferric sulfate. More preferably, in yet another embodiment of the present invention, in the preparation method of the high-concentratio...

Embodiment 1

[0035] (1) Oxidation to prepare high-concentration D-arabinose crude solution

[0036] The raw material formula of D-arabinose liquid adopts mass percent, and 175 grams of sodium gluconate are added in the 3 liters of reaction tanks that are added with 1176 grams of water, make concentration be 13% weight 1354g, add 2.98g of soluble iron salt iron sulfates as catalyst, The consumption of catalyst is 0.017 of the molar weight of sodium gluconate.

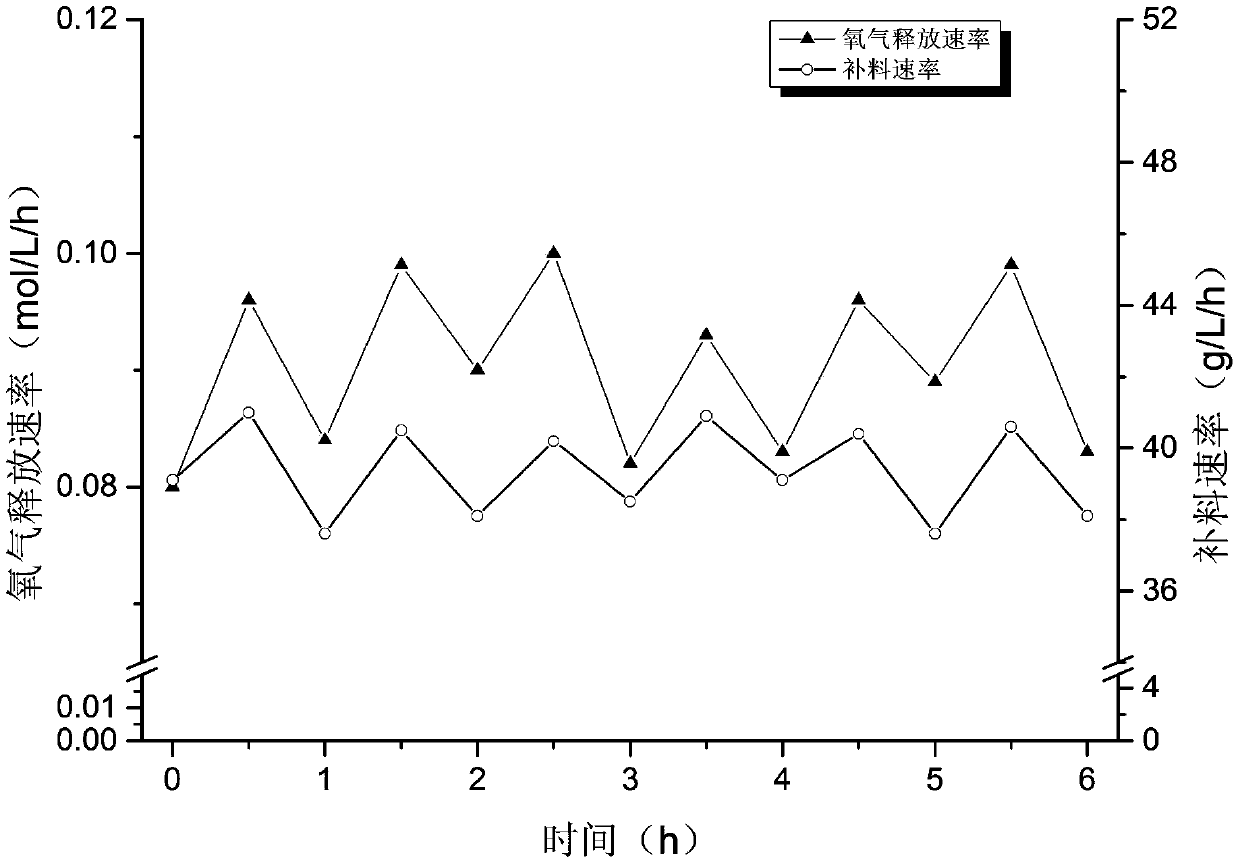

[0037] Such as figure 1 Shown, the sodium gluconate that feeds is added according to tail gas (oxygen) mass spectrometer system control feeds in the reaction process, and oxygen amount is controlled at 0.06-0.09moL / (L h), and the sodium gluconate mass concentration that feeds is 60% And the feeding liquid is placed in an environment of 80° C. to prevent the crystallization of sodium gluconate, and the feeding amount is 38-42 g / (L·h). The flow acceleration rate changes according to the change of tail oxygen. When the tail oxygen is ...

Embodiment 2

[0052] (1) Preparation of D-arabinose solution

[0053] The D-arabinose liquid raw material formula adopts mass percentage, and 175 gram sodium gluconate is added in the 3 liters of reaction tanks that are added with 1060 gram water, is made into mass percentage concentration and is 14% weight 1235g, and sodium gluconate is according to process oxygen tail mass spectrometer The system counter-controls feed feeding, the oxygen amount is controlled at 0.08-0.09moL / (L h), the mass concentration of sodium gluconate fed into feed is 60%, and the fed feed liquid is placed in an environment of 80°C to prevent sodium gluconate from crystallizing. The amount is 38-42g / (L·h). Slowly add hydrogen peroxide while stirring, hydrogen peroxide concentration is 30% weight 800mL in hydrogen peroxide, temperature of reaction is 50 ℃, the adding speed of hydrogen peroxide is 150-300mL / h, the equivalent of hydrogen peroxide is 5 times of sodium gluconate equivalent.

[0054] (2) Refining of D-ara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com