Resin-base nonlinear composite material for low temperature environment and preparation method of resin-base nonlinear composite material

A composite material, low temperature environment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

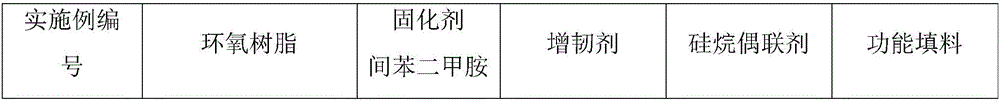

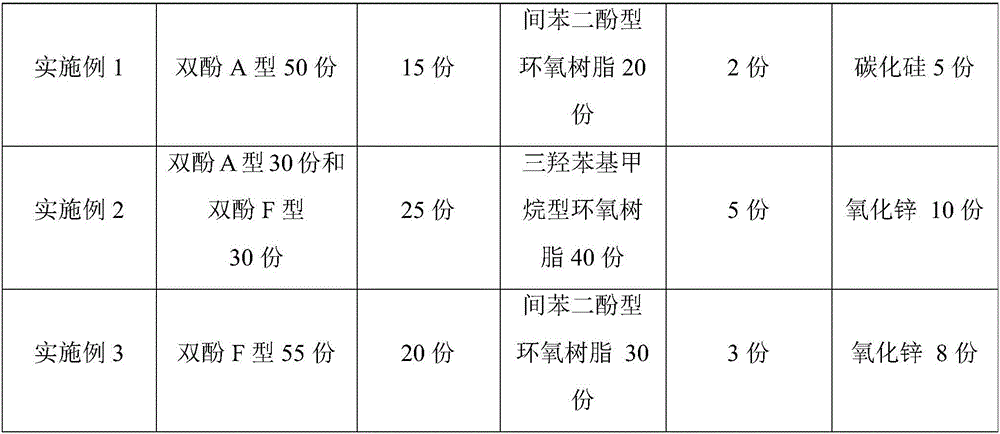

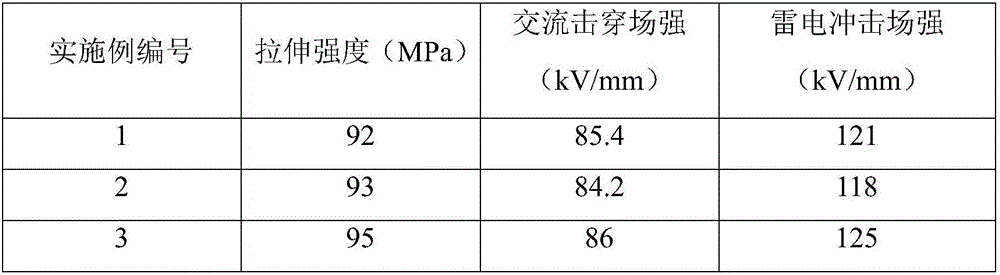

Examples

Embodiment 1

[0026] The preparation process of resin-based nonlinear composite materials for low temperature environment is as follows:

[0027] (1) First add a weighed functional filler into the flask with a particle size of 10-100nm, then add an appropriate amount of anhydrous ethanol and a silane coupling agent in turn, and stir the above mixture for 2.5 hours with a magnetic stirrer until it is evenly mixed Afterwards, the solution was suction-filtered, put into a drying oven, and dried at about 100°C for 10 hours for later use.

[0028] (2) Add the weighed epoxy resin matrix and the above-mentioned functional fillers into the four-necked flask, and stir the mixed solution with a mixer for about 0.5h, so that the epoxy resin matrix and the functional fillers are fully mixed evenly.

[0029] (3) Add the weighed toughening agent and curing agent in sequence to the above mixed solution, and stir the mixture with a mixer for 40 minutes until the mixture becomes transparent without bubbles....

Embodiment 2

[0033] The preparation process of resin-based nonlinear composite materials for low temperature environment is as follows:

[0034] (1) First, add a weighed functional filler into the flask with a particle size of 10-100nm, then add an appropriate amount of anhydrous ethanol and a silane coupling agent in turn, and stir the above mixture for 3.5 hours with a magnetic stirrer until it is evenly mixed Afterwards, the solution was suction-filtered, put into a drying oven, and dried at about 100°C for 12 hours for later use.

[0035] (2) Add the weighed epoxy resin matrix and the above-mentioned functional fillers into the four-necked flask, and stir the mixed solution with a mixer for about 1 hour to fully mix the epoxy resin matrix and the functional fillers.

[0036] (3) Add the weighed toughening agent and curing agent in sequence to the above mixed solution, and stir the mixture for 1 hour with a stirrer until the mixture becomes transparent without bubbles.

[0037] (4) Use...

Embodiment 3

[0040] The preparation process of resin-based nonlinear composite materials for low temperature environment is as follows:

[0041] (1) First, add a weighed functional filler into the flask with a particle size of 10-100nm, then add an appropriate amount of anhydrous ethanol and a silane coupling agent in turn, and stir the above mixture for 3 hours with a magnetic stirrer, and wait until it is evenly mixed Suction filter the solution, put it in a drying oven, and dry it at about 100°C for 11 hours for later use.

[0042] (2) Add the weighed epoxy resin matrix and the above-mentioned functional fillers into the four-necked flask, and stir the mixed solution with a mixer for about 50 minutes to fully mix the epoxy resin matrix and the functional fillers.

[0043] (3) Add the weighed toughening agent and curing agent in sequence to the above mixed solution, and stir the mixture with a mixer for 50 minutes until the mixture becomes transparent without bubbles.

[0044] (4) Use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com