A kind of silicon quantum dot and its preparation method and application

A technology of silicon quantum dots and quantum dot solution, applied in the field of silicon quantum dots and their preparation, can solve the problems of complicated and lengthy process, rivalry of semiconductor silicon quantum dots, etc., and achieves simple and fast operation process, excellent water solubility, and abundant and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing silicon quantum dots, comprising the following steps:

[0042] ①Weigh 1.86g of sodium citrate dihydrate, add 40mL of deionized water to fully stir to dissolve, and then bubble nitrogen for 30min.

[0043] ② Measure 10mL of 3-aminopropyltrimethoxysiloxane, add it to the solution of sodium citrate, stir well for 10min, then transfer the solution into a microwave reaction tank.

[0044] ③ Set the reaction temperature to 160°C and the reaction time to 15 minutes.

[0045] ④ After the solution was cooled to room temperature, the crude product was taken out, transferred into a dialysis bag with a molecular weight cut-off of 1 kDa, and the water was replaced every 4 hours to ensure that the total dialysis time was 12 hours to obtain a silicon quantum dot solution.

[0046] ⑤ Place the silicon quantum dot solution obtained above in a freeze dryer, set the cooling temperature to minus 40° C., and dry for 72 hours; obtain silicon quantum dots.

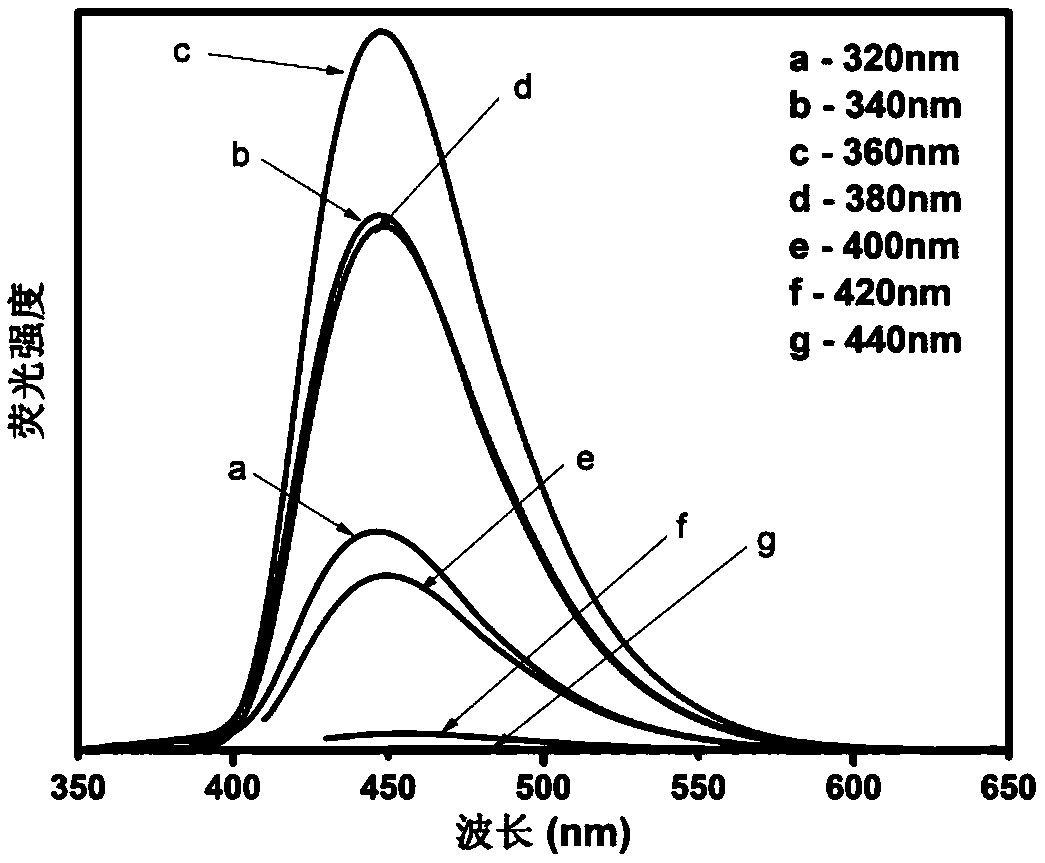

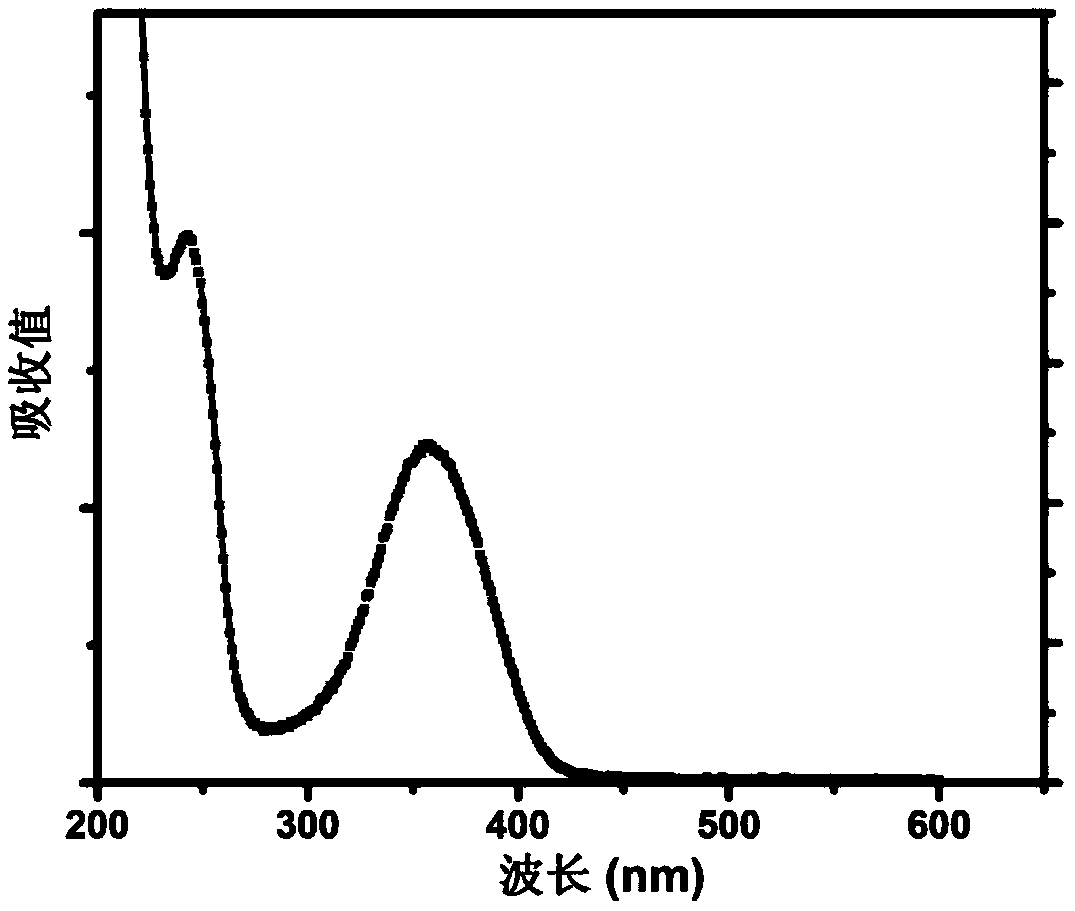

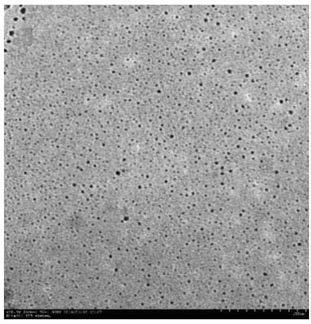

[0047] Af...

Embodiment 2

[0049] The same steps as in Example 1 were taken to prepare silicon quantum dots, except that the sodium citrate dihydrate in Example 1 was replaced with 1.40 g of citric acid, and other reaction conditions were not changed.

[0050] Through TEM characterization, it is shown that the particle morphology is uniform, and the average particle diameter is about 2.5nm, and its particle diameter is slightly increased compared with the product obtained in Example 1; the absolute quantum efficiency measured value is 13.37%; the solution after dialysis is placed for 15 Precipitation occurs after more than 1 day, the particle agglomeration phenomenon is serious, and the storage stability is not good, indicating that its surface groups are relatively complex.

Embodiment 3

[0052] Take the same steps as in Example 1 to prepare silicon quantum dots, the difference is that the 3-aminopropyltrimethoxysiloxane in Example 1 is replaced with 10mL of N-β (aminoethyl)-γ-aminopropyl Triethoxysilane, other reaction conditions were not changed.

[0053] After TEM characterization, it shows that the particles have a uniform shape and an average particle size of about 2.4nm; the absolute quantum efficiency is 65.09%; the solution after dialysis is placed for more than 15 days to precipitate, the particle agglomeration is serious, and its storage stability is not good. It shows that its surface groups are more complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com