Woven fully-degradable magnesium alloy airway stent and preparation method thereof

A magnesium alloy, fully degradable technology, applied in stents, medical science, prostheses, etc., can solve the problems of poor support force and resilience, and achieve the effect of improving support force and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

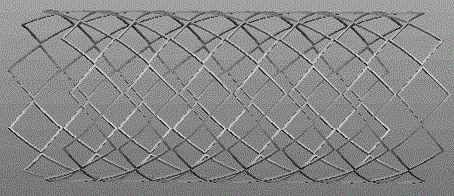

[0024] A braided fully degradable magnesium alloy airway stent, the preparation process is as follows:

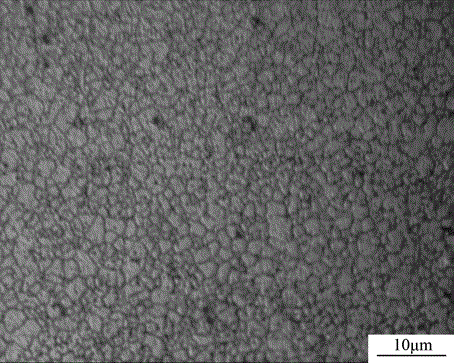

[0025] (1) Preparation of Mg-Zn-Y-Nd alloy wire: (a) as-cast Mg-Zn-Y-Nd alloy (for its preparation method, please refer to patent ZL201110043303.8, the same below) and homogenize at 480°C After treatment for 48 hours, an alloy rod with a diameter of 3 mm was prepared by hot extrusion at a temperature of 380 °C, an extrusion ratio of 44, and an extrusion rate of 2 m / min; (b) a traditional drawing device was used at room temperature to The alloy bar is drawn 3 to 4 times, and the single-pass deformation of the drawing is 15%. After the drawing is completed, it is annealed. The annealing temperature is 200 ° C, and the annealing time is 15 minutes; The diameter is 0.28mm wire, the tensile strength of 0.28mm wire is 300MPa, the yield strength is 220MPa, and the elongation is 15% measured by a universal tensile machine; the internal structure of the wire is 1~3µm through a metal...

Embodiment 2

[0030] A braided fully degradable magnesium alloy airway stent, the preparation process is as follows:

[0031] (1) Preparation of Mg-Zn-Y-Nd alloy wire: same as step (1) of Example 1;

[0032] (2) Weaving forming: same as step (2) of embodiment 1;

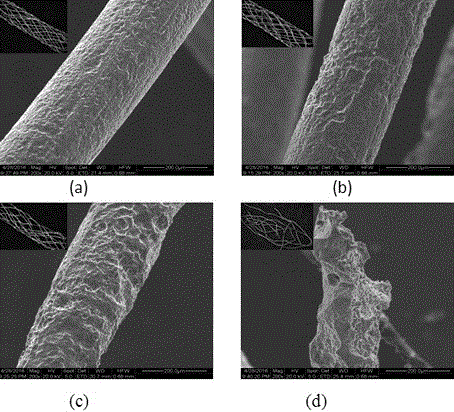

[0033] (3) Surface treatment: The above-mentioned heat-set magnesium alloy airway bracket was treated for 5 seconds in an electrolytic polishing solution composed of 5v% glycerin, 25v% phosphoric acid and 70v% alcohol, polishing voltage 10V, current 2A , then immerse the polished stent in a coupling agent for coupling treatment, the immersion time is 3min, the coupling agent is 5v% silane KH-570 aqueous solution, after coupling, the stent is dried, and 1v% chitosan The aqueous solution is dip-coated on the inner and outer surfaces of the stent, and the dip-coating is repeated 6 times, each dipping time is 10s, and it is dried. The tensile strength of the stent is 380MPa, the elongation is 35%, and the support force is 5N, measure...

Embodiment 3

[0036] A braided fully degradable magnesium alloy airway stent, the preparation process is as follows:

[0037] (1) Preparation of Mg-Zn-Y-Nd-Zr alloy wire: (a) cast Mg-Zn-Y-Nd-Zr alloy (for its preparation method, refer to patent ZL201310418031.4, the same below) at 460°C Homogenization treatment was carried out under the condition of hot extrusion method to prepare alloy rods with a diameter of 3mm, the extrusion temperature was 400°C, the extrusion ratio was 44, and the extrusion speed was 2m / min; (b) the traditional drawing method was used at room temperature The drawing device draws the alloy bar 3~4 times, the single-pass deformation of the drawing is 15%, and annealing treatment is carried out after the drawing is completed, the annealing temperature is 250°C, and the annealing time is 10min; (c) repeat the step (b ) until it is made into a wire with a diameter of 0.24mm. The tensile strength is 330MPa, the yield strength is 250MPa, and the elongation is 18%. The inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com