A kind of degradable rare earth magnesium alloy medical biological material and preparation method

A biomaterial, rare earth magnesium technology, applied in the field of magnesium alloy materials, can solve problems such as excessive corrosion rate, poor mechanical integrity, and insufficient time for healing, and achieve excellent mechanical properties, good mechanical properties and processing properties, and complete degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the degradable rare earth magnesium alloy medical biological material of the present invention comprises the following steps:

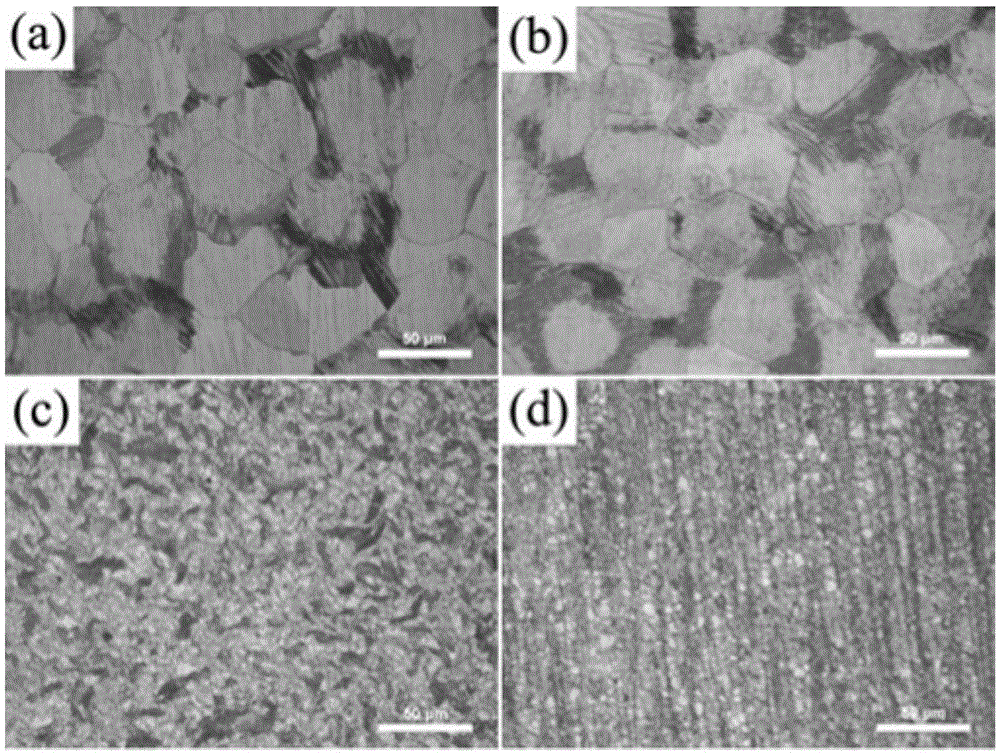

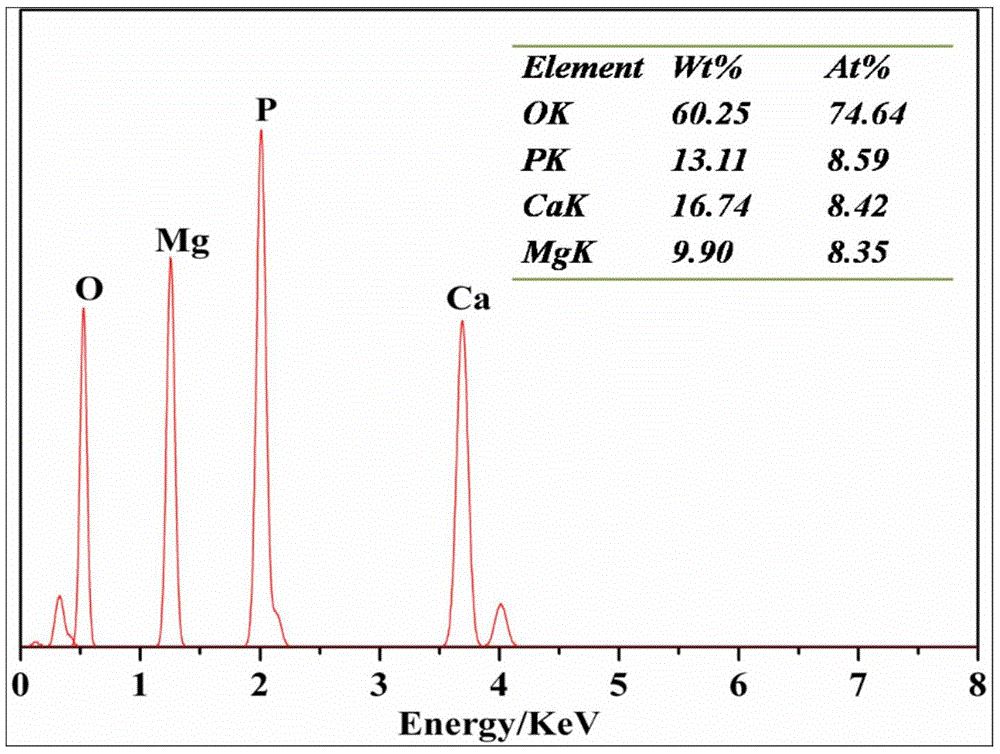

[0025] (1) Alloy smelting: Raw materials are batched according to the ratio, the surface is sandblasted and peeled and preheated to 200°C; the cast iron crucible is preheated to 300°C, and SF 6 :CO 2 Add magnesium ingots to the protective gas with a volume ratio of 1:200; when the metal in the crucible is completely melted and the melt temperature reaches 740°C, add metal zinc, magnesium-yttrium master alloy, and magnesium-dysprosium master alloy in sequence; when the melt temperature When it reaches 770°C, add magnesium-zirconium master alloy, after stirring, when the melt temperature drops to 730°C, continue to pass in argon gas for refining for 5 minutes, and stand at 730°C for 20 minutes; when the melt temperature drops to 720°C , casting the alloy liquid into a water-cooled mold to make a degradable rare earth ma...

Embodiment 1

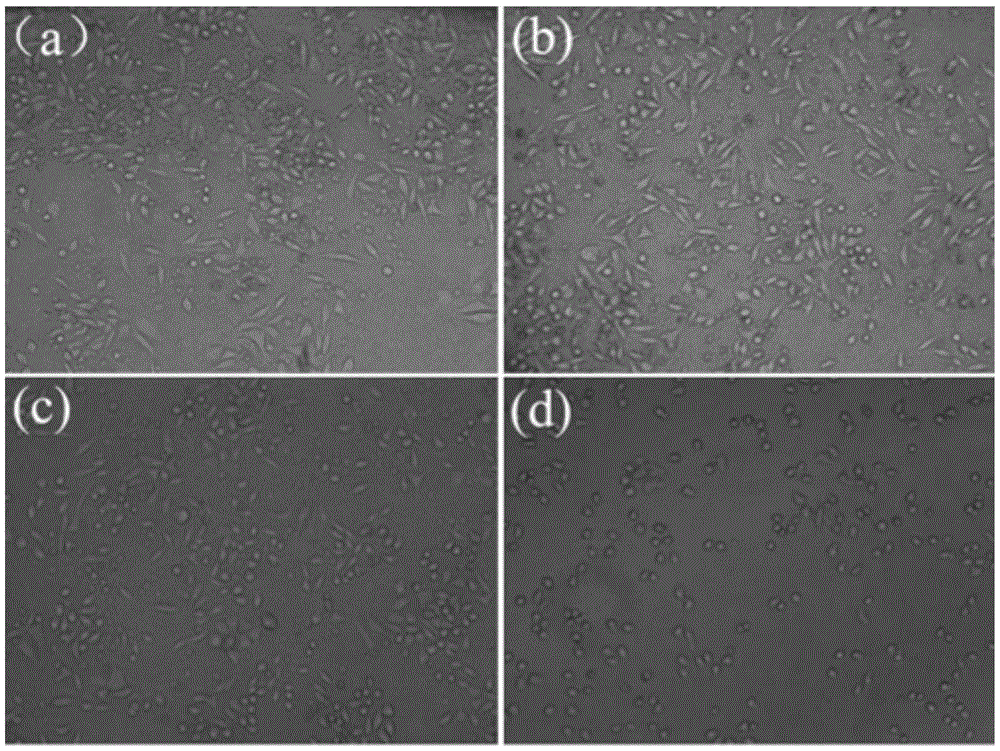

[0030] Example 1: Mg-0.5Y-0.1Dy-0.8Zn-0.4Zr degradable rare earth magnesium alloy

[0031] The preparation method of Mg-0.5Y-0.1Dy-0.8Zn-0.4Zr degradable rare earth magnesium alloy is as follows:

[0032] 1. Preparation of magnesium-rare earth yttrium and magnesium-zirconium master alloys. According to the ratio of 80wt% by mass of magnesium metal and 20wt% by mass of rare earth yttrium, the metal magnesium and rare earth yttrium are put into a cast iron or graphite crucible, heated and melted and heated to 780°C, stirred evenly and left to stand for 20 minutes, then Cast into magnesium-yttrium master alloy ingot. SF is introduced into the smelting process 6 :CO 2 Protective gas with a volume ratio of 1:200. According to the same process parameters and raw material ratio, magnesium-yttrium, magnesium-zirconium and magnesium-dysprosium master alloys were prepared respectively. A magnesium-zirconium master alloy ingot is prepared by adopting the above-mentioned process in...

Embodiment 2

[0040] Example 2: Mg-1.0Y-0.3Dy-1.0Zn-0.4Zr degradable rare earth magnesium alloy

[0041] The preparation method of Mg-1.0Y-0.3Dy-1.0Zn-0.4Zr degradable rare earth magnesium alloy is as follows:

[0042] 1. Preparation of magnesium-rare earth yttrium and magnesium-zirconium master alloys. According to the ratio of 80% by mass of magnesium metal and 20% by mass of rare earth yttrium, metal magnesium and rare earth yttrium are put into a cast iron or graphite crucible, heated and melted and heated to 780°C, stirred evenly and left to stand for 20 minutes. It is then cast into a magnesium-yttrium master alloy ingot. SF is introduced into the smelting process 6 :CO 2 Protective gas with a volume ratio of 1:200. According to the same process parameters and raw material ratio, magnesium-yttrium, magnesium-zirconium and magnesium-dysprosium master alloys were prepared respectively. The magnesium-zirconium master alloy ingot is prepared by adopting the above-mentioned process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com