SnS2/TiO2 photocatalyst filter screen and preparation method thereof

A photocatalyst and filter screen technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem that nano-titanium oxide powder cannot be reused, shorten the time used, and the process is simple and environmentally friendly. , the effect of improving the photocatalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

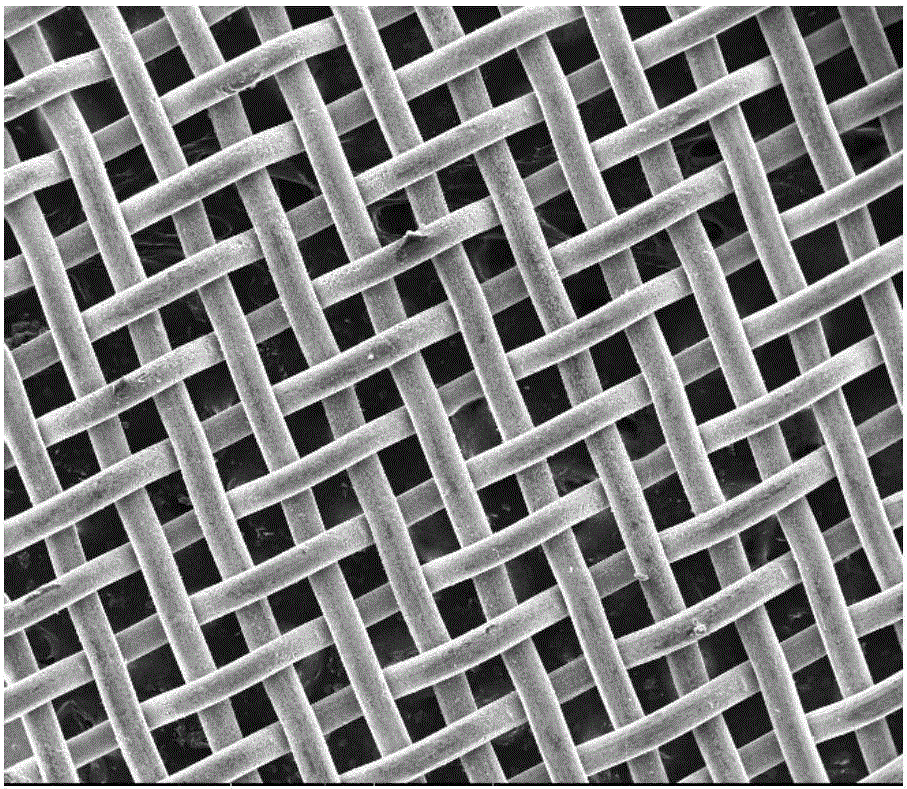

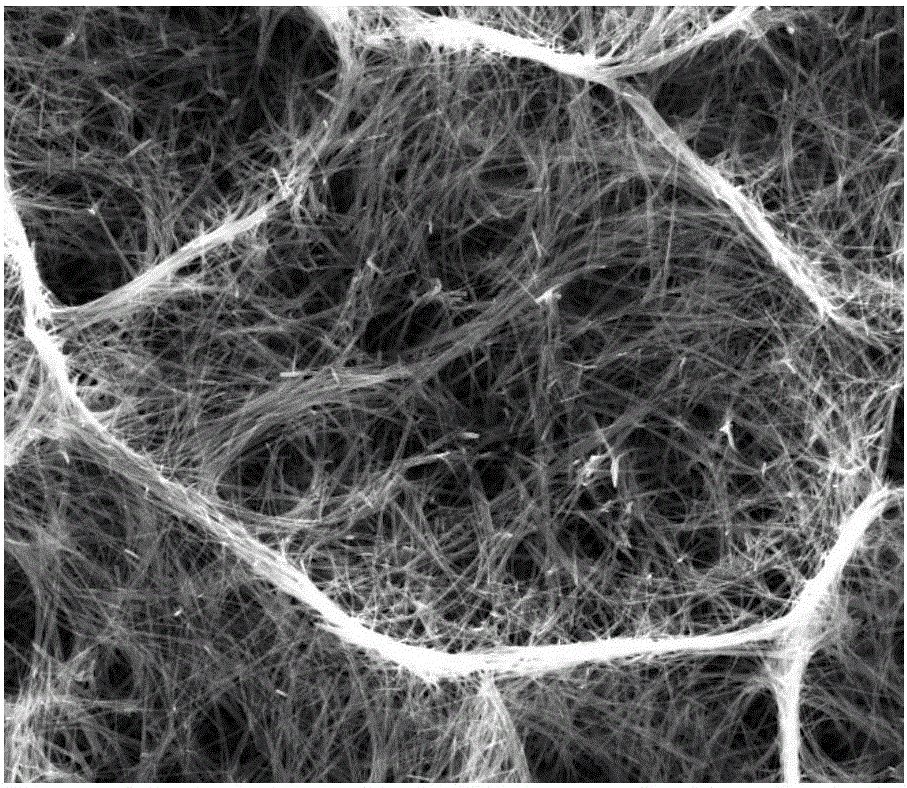

[0030] (1) Soak the cleaned titanium mesh in a mixture of polyethylene glycol and sodium hydroxide, wherein the volume ratio of polyethylene glycol PEG: water is 1:1, and the concentration of sodium hydroxide solution is 0.5M. Add 0.2M urea to carry out hydrothermal reaction, the hydrothermal temperature is 220°C, and the hydrothermal time is 25 hours. After the hydrothermal reaction, the titanium mesh was washed with water, soaked in 0.1M hydrochloric acid for 1 hour, washed with water, and dried. Put it into an annealing furnace, heat it to 400°C, keep it warm for 2 hours, and cool down with the furnace. A filter screen with titanium oxide nanowires grown on the surface is prepared.

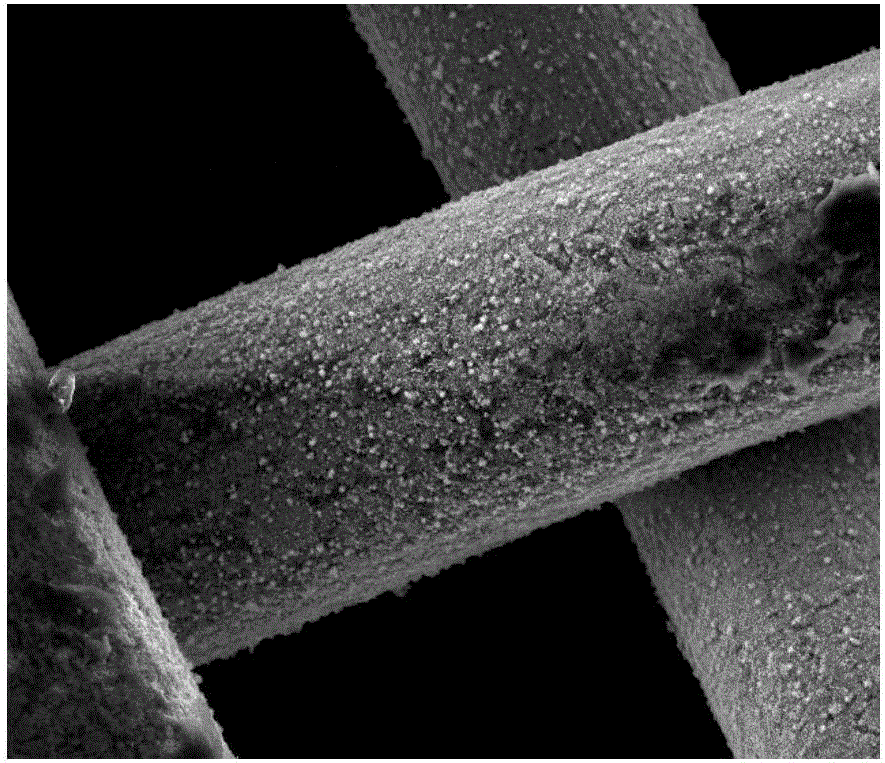

[0031] (2) Put the filter screen grown with titanium oxide nanowires into the hydrothermal tank, and the hydrothermal agent is SnCl 4 0.1M, EDTA concentration is 0.1M, Na 2 S concentration is 0.2M, SnCl 4 :Na 2 The S molar ratio is 1:2.0. The hydrothermal temperature is 110°C, and the hy...

Embodiment 2

[0034] (1) Soak the cleaned titanium screen in a mixture of polyethylene glycol, urea and sodium hydroxide, wherein the polyethylene glycol PEG: water volume ratio is 0.2:1, and the concentration of sodium hydroxide solution is 0.5M . Add 0.5M urea to carry out hydrothermal reaction, the hydrothermal temperature is 160°C, and the hydrothermal time is 5 hours. After the hydrothermal reaction, the titanium mesh was washed with water, soaked in 0.1M hydrochloric acid for 1 hour, washed with water, and dried. Put it into an annealing furnace, heat it to 500°C, keep it warm for 2 hours, and cool it with the furnace. A filter screen with titanium oxide nanosheets grown on the surface was prepared.

[0035] (2) Put the filter screen grown with titanium oxide nanosheets into the hydrothermal tank, and the hydrothermal agent is SnCl 4 0.3M, EDTA concentration is 0.1M, ammonia concentration is 1M, Na 2 S concentration is 0.78M, SnCl 4 :Na 2 The molar ratio of S is 1:2.6. The hyd...

Embodiment 3

[0039] (1) Soak the cleaned titanium screen in a mixture of polyethylene glycol, urea and sodium hydroxide, wherein polyethylene glycol PEG: water volume ratio is 0.5:1, urea 0.8M, sodium hydroxide solution Concentration 0.5M. Carry out hydrothermal reaction, hydrothermal temperature 200 ℃, hydrothermal time 15 hours. After the hydrothermal reaction, the titanium mesh was washed with water, soaked in 0.1M hydrochloric acid for 1 hour, washed with water, and dried. Put it into an annealing furnace, heat it to 700°C, keep it warm for 4 hours, and cool down with the furnace. A filter screen with titanium oxide nanowires grown on the surface is prepared.

[0040] (2) Put the filter screen grown with titanium oxide nanowires into the hydrothermal tank, and the hydrothermal agent is SnCl 4 0.2M, EDTA concentration is 0.1M, thioacetamide concentration is 0.24M, ammonia concentration is 0.1M, SnCl 4 : Thioacetamide molar ratio is 1:2.2. The hydrothermal temperature is 130°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com