A kind of rod-like oligomeric carbon nitride and its preparation method and application

A technology of polycarbonitride and carbonitride, which is applied in the field of oligopolycarbonitride and its preparation, can solve the problems of weak light absorption ability, few active sites, difficult to capture bacteria, etc., and achieve low recombination rate and no secondary Secondary pollution, enhance the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

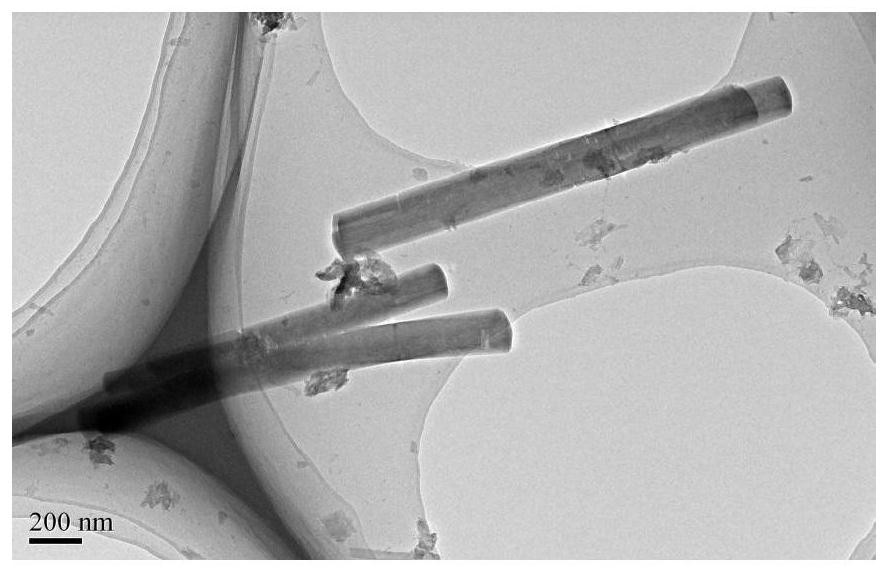

[0049] This example provides a kind of oligomeric carbon nitride, which is prepared through the following steps:

[0050] (1) Weigh 15g of melamine and 5g of silica pellets into a crucible containing 20mL of water, heat and stir for 30min to fully dissolve them, put them into a high-temperature box-type electronic furnace at 500°C for 4h, and then cool naturally to At room temperature, the white solid was collected by triturating.

[0051] (2) Take by weighing 1.5g of the above-mentioned prepared white solid and put it into a 100mL beaker, pour into 25mL of 50% hydrofluoric acid by volume, stir for 60min and wash the product obtained three times with ethanol and deionized water respectively, Then dry in a vacuum oven at 80 °C for 6 h.

[0052] (3) Weigh 400 mg of the product obtained in step (2) into 100 mL of DMSO solution, and stir at 25° C. for 7 days. Use a 10000rcf centrifuge to remove the centrifuged sediment, and then use a 20000rcf centrifuge to wash the obtained mat...

Embodiment 2

[0063] This example provides a kind of oligomeric carbon nitride, which is prepared through the following steps:

[0064] (1) Weigh 15g of melamine and 5.0g of silica pellets into a crucible containing 20mL of water, heat and stir for 30min to fully dissolve them, then put them into a high-temperature box-type electronic furnace at 500°C for 4h, and then cool naturally to room temperature and triturated to collect a white solid.

[0065] (2) Take by weighing 1.5g of the above-mentioned prepared white solid and put it into a 100mL beaker, pour into 25mL of 50% hydrofluoric acid by volume, stir for 60min and wash the product obtained three times with ethanol and deionized water respectively, Then dry in a vacuum oven at 80°C for 6 hours to obtain oligomeric carbon nitride.

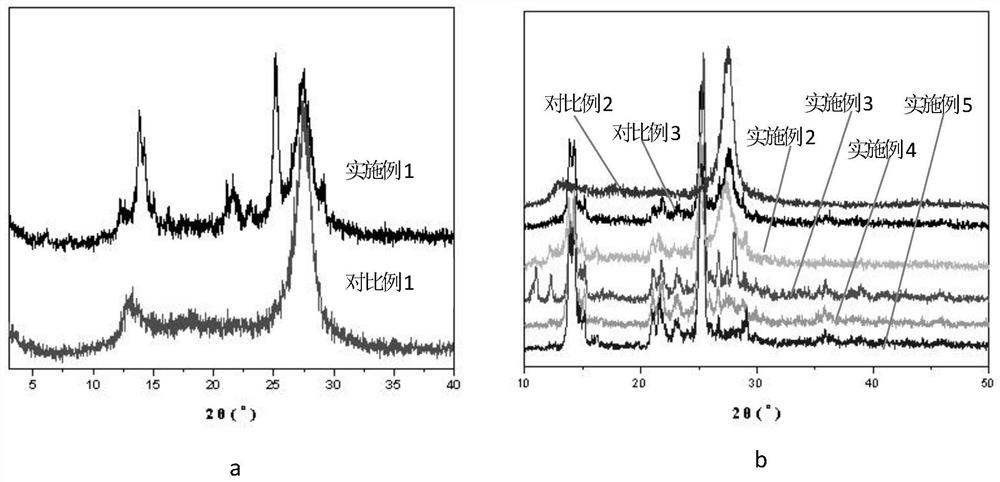

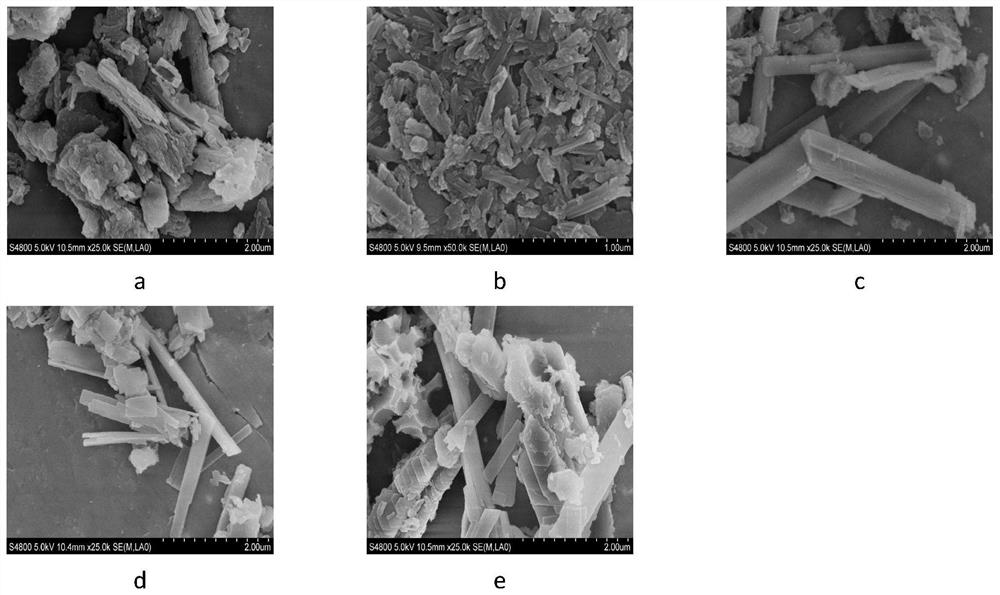

[0066] The obtained oligomeric carbon nitride was subjected to XRD analysis, ultraviolet-visible light absorption experiment, SEM test and photocatalytic activity test respectively. XRD analysis results se...

Embodiment 3

[0075] This example provides an oligomeric carbon nitride, the preparation process of which is basically the same as in Example 2, except that the amount of silicon oxide is changed to 0.5g.

[0076] The obtained oligomeric carbon nitride was analyzed by XRD, ultraviolet-visible light absorption experiment and photocatalytic activity test. XRD analysis results see figure 1 b, showing that the obtained oligomeric carbon nitride is a oligomeric carbon nitrogen material. The structure of the ultraviolet-visible light absorption experiment is as follows: Figure 4 As shown, it can be seen that the oligomeric carbon nitride of this embodiment has certain visible light absorption. For photocatalytic activity results see Figure 6 , indicating that the oligomeric carbon nitride of this example has certain photocatalytic activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com